Lpf fuel system diagnosis -133 – JLG 450A_AJ Series II Service Manual User Manual

Page 183

SECTION 3 - CHASSIS & TURNTABLE

3121180

– JLG Lift –

3-133

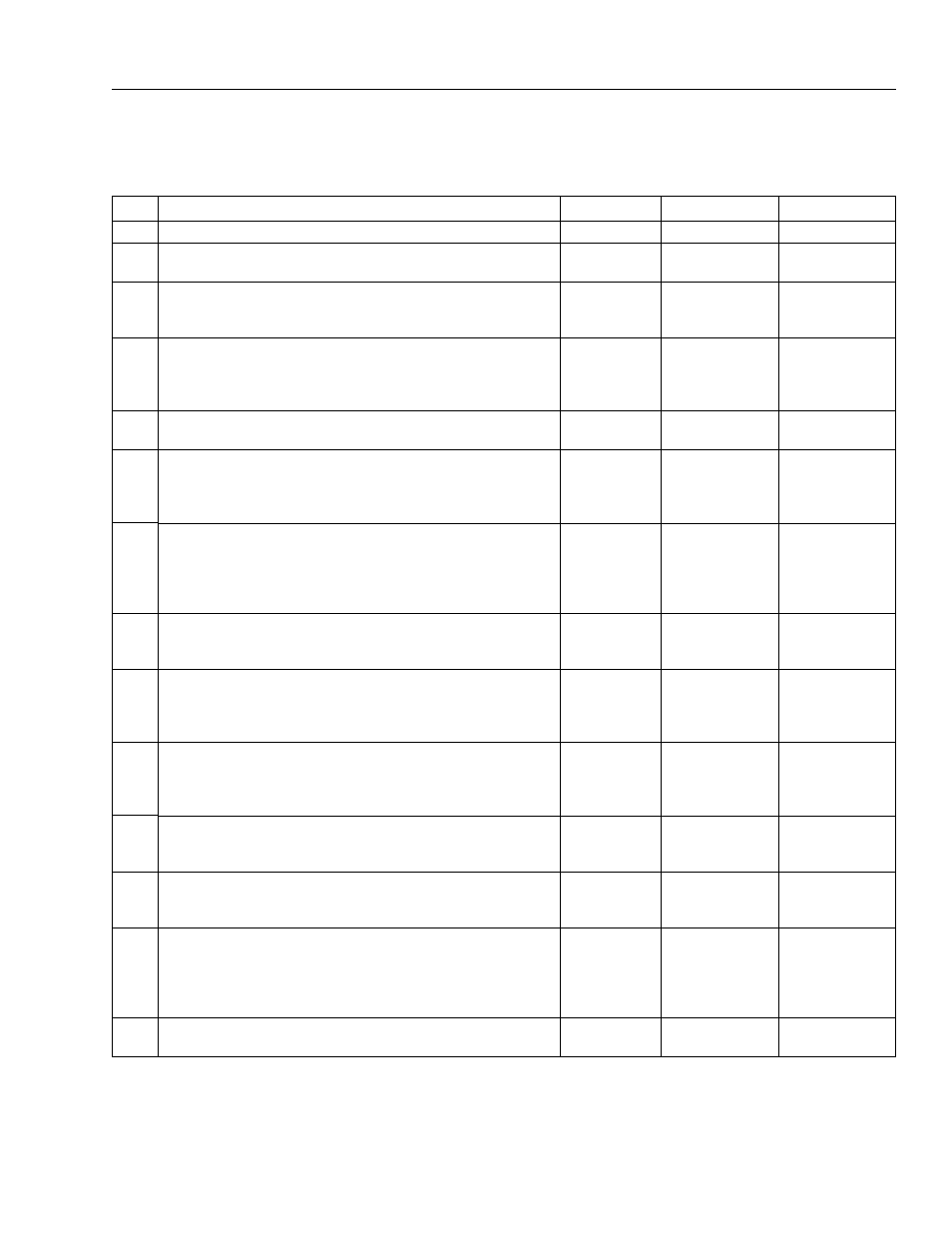

Table 3-14. LPF Fuel System Diagnosis

STEP

ACTION

VALUE(S)

YES

NO

1

Were you referred to this procedure by a DTC diagnostic chart?

- -

Go to Step 3

Go to Step 2

2

Perform On Board Diagnostic (OBD) System Check.

Are any DTCs present in the ECM?

- -

Go to the

applicable DTC Table

Go to Step 3

3

Verify LPG fuel tank has a minimum of 1/4 tank of fuel, manual valve is open and

tank quick connect is fully engaged

Does vehicle have fuel?

- -

Go to Step 4

- -

4

1. Connect a water column gauge or a manometer to Low Pressure Regulator

(LPR) secondary test port.

2. Start engine and allow it to reach operating temperature.

Does engine start and run?

- -

Go to Step 5

Go to Step 8

5

With engine idling, observe pressure reading for LPR secondary pressure.

Does fuel pressure fluctuate rhythmically OUTSIDE specified range?

-1.0" to

-2.0" w.c

Go to Step 25

Go to Step 6

6

1. Disconnect EPR electrical connectors. NOTE: This action will cause a DTC to

be set by the ECM

2. With engine idling, observe pressure reading on secondary test port.

Is fuel pressure WITHIN specified range?

-1.0" to

-2.0" w.c

Go to Fuel Control

System Diagnosis

Go to Step 7

7

1. Inspect air intake stream between mixer assembly and throttle body for leaks.

2. Inspect fuel hose connection between LPR and mixer assembly for damage

or leakage.

3. Inspect vacuum hoses for leaks

Was a problem found and corrected?

- -

Go to Step 26

Go to Step 22

8

1. Connect a water column gauge or a manometer to LPR secondary test port.

2. Crank engine and observe pressure reading for LPR secondary pressure.

Does fuel pressure indicate a vacuum is present?

- -

Go to Step 12

Go to Step 9

9

1. Remove Air induction hose to mixer

2. Observe air valve for movement while engine is cranking. Note: Movement of

air valve will be minimal at cranking speeds.

Does air valve move when engine is cranked?

- -

Go to Step 11

Go to Step 10

10

1. Inspect air intake stream to mixer assembly and throttle body for vacuum

leaks.

2. Inspect vacuum hoses from mixer for proper connection and condition.

Was a problem found and repaired?

- -

Go to Step 26

Go to Step 24

11

Inspect fuel hose connection between LPR and mixer assembly for damage or

leakage.

Was a problem found and repaired?

- -

Go to Step 26

Go to Step 12

12

1. Connect a 0-10 psi gauge to primary test port of LPR.

2. Crank engine and observe pressure reading for LPR primary pressure.

Is fuel pressure ABOVE specified value?

1- 3 PSI

Go to Step 22

Go to Step 13

13

1. Turn OFF ignition.

2. Disconnect LPL connector.

3. Install a test light between pins of LPL connector.

4. Crank engine. Test light should illuminate.

Does test light illuminate?

- -

Go to Step 14

Go to Step 16

14

Using a DVOM, check resistance of Low Pressure Lock-off (LPL).

Is resistance within specified range?

12W - 16W

Go to Step 15

Go to Step 23