7 adjustment procedure for lockout valve, Lockout cylinder bleeding (early cylinders), Lockout cylinder bleeding (ram cylinders) – JLG 450A_AJ Series II Service Manual User Manual

Page 114: Adjustment procedure for lockout valve -64, Valve adjustment -64

SECTION 3 - CHASSIS & TURNTABLE

3-64

– JLG Lift –

3121180

3.7 ADJUSTMENT PROCEDURE FOR

LOCKOUT VALVE

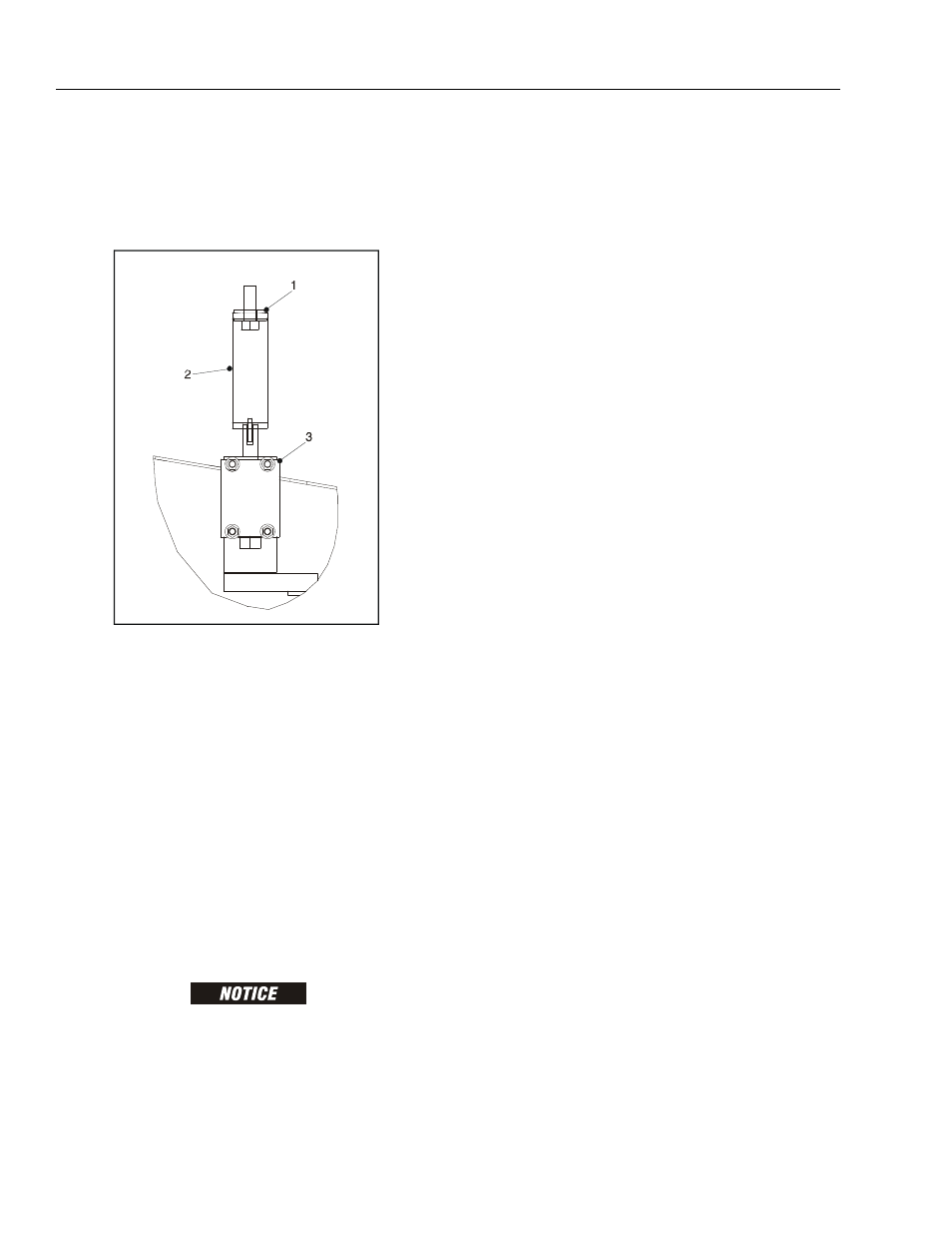

11. With turntable centered, adjust bracket with washers

to push plunger in 5/16" ± 1/16" (7.9 ± 1.6 mm).

1. The ideal adjustment is 3/8" (9.5 mm). Do not push

plunger in more than 3/8" (9.5 mm). The extra

adjustment is needed for turntable bearing play.

3.8 OSCILLATING AXLE BLEEDING

PROCEDURE AND LOCKOUT TEST

Lockout Cylinder Bleeding (Early Cylinders)

NOTE: The following procedure is for machines built in the

USA prior to S/N 0300107512 and machines built in

Belgium prior to S/N 1300003222.

FULLY LOWER PLATFORM AND CENTER BOOM OVER REAR AXLE

BEFORE STARTING BLEEDING PROCEDURE.

ENSURE MACHINE IS ON A LEVEL SURFACE AND REAR WHEELS

ARE BLOCKED, AND BRAKE WIRE IS DISCONNECTED.

1. Make sure machine is on a level surface.

2. Center boom over rear axle to make sure cam valve

in the rotary coupling is depressed.

3. Place chocks under tires to ensure machine does

not move. Disable machine brakes by disconnecting

brake solenoid(s) on brake valve.

4. Use suitable containers to catch excess hydraulic

fluid. Place containers under each lockout cylinder.

5. Open one bleeder screw at a time.

6. Start engine, position drive control lever forward or

reverse.

7. Close bleeder screws when all air is dissipated

(bled).

8. Reconnect brake solenoid(s) and remove wheel

chocks.

9. Perform oscillating axle lockout test.

10. If necessary, repeat steps 1 thru 7.

Lockout Cylinder Bleeding (Ram Cylinders)

NOTE: The following procedure is for machines built in the

USA S/N 0300107512 to present and machines built

in Belgium S/N 1300003222 to present.

1. Position turntable to normal stowed position so axle

is free to oscillate. Drive charge pressure will pass

through lockout valve built into swivel and down to

pilot section of holding valves on cylinders. This will

automatically purge air from pilot section of circuit.

2. Attach end of clear tubing to bleeder valve nipple

and place other end in container to catch oil. Using

a 3/8" wrench, slowly turn bleeder valve counter-

clockwise to bleed air from cylinder. Have operator

in platform just crack drive controller in reverse. This

will activate brake valve sending charge pressure to

lockout cylinder. Close valve when an unbroken,

steady stream of oil is seen.

3. Repeat procedure for other lockout cylinder.

1. Washer

2. Bracket

3. Lockout Valve

Figure 3-47. Valve Adjustment