2 service and guidelines, General, Safety and workmanship – JLG 450A_AJ Series II Service Manual User Manual

Page 38: Cleanliness, Components removal and installation, Service and guidelines -2, Inspection and maintenance -2, 2 service and guidelines general

SECTION 2 - GENERAL

2-2

– JLG Lift –

3121180

2.2 SERVICE AND GUIDELINES

General

The following information is provided to assist you in the

use and application of servicing and maintenance proce-

dures contained in this manual.

Safety and Workmanship

Your safety, and that of others, is the first consideration

during maintenance of equipment. Always be conscious

of weight. Never attempt to move heavy parts without the

aid of a mechanical device. Do not allow heavy objects to

rest in an unstable position. When raising a portion of the

equipment, ensure that adequate support is provided.

Cleanliness

1. The most important single item in preserving the

long service life of a machine is to keep dirt and for-

eign materials out of the vital components. Precau-

tions have been taken to safeguard against this.

Shields, covers, seals, and filters are provided to

keep air, fuel, and oil supplies clean; however, these

items must be maintained on a scheduled basis in

order to function properly.

2. At any time when air, fuel, or oil lines are discon-

nected, clean openings, fittings, and adjacent areas.

As soon as a line or component is disconnected,

cap or cover all openings to prevent entry of foreign

matter.

3. Clean and inspect all parts during servicing or main-

tenance. Ensure all passages and openings are

unobstructed. Cover all parts to keep them clean. Be

sure all parts are clean before they are installed.

Keep new parts in their containers until needed.

Components Removal and Installation

1. Use adjustable lifting devices if mechanical assis-

tance is required. All slings (chains, cables, etc.)

should be parallel to each other and as near perpen-

dicular as possible to top of part being lifted.

2. Should it be necessary to remove a component on

an angle, keep in mind the capacity of an eyebolt or

similar bracket lessens, as the angle between the

supporting structure and component becomes less

than 90 degrees.

3. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc., have been

removed and no adjacent parts are interfering.

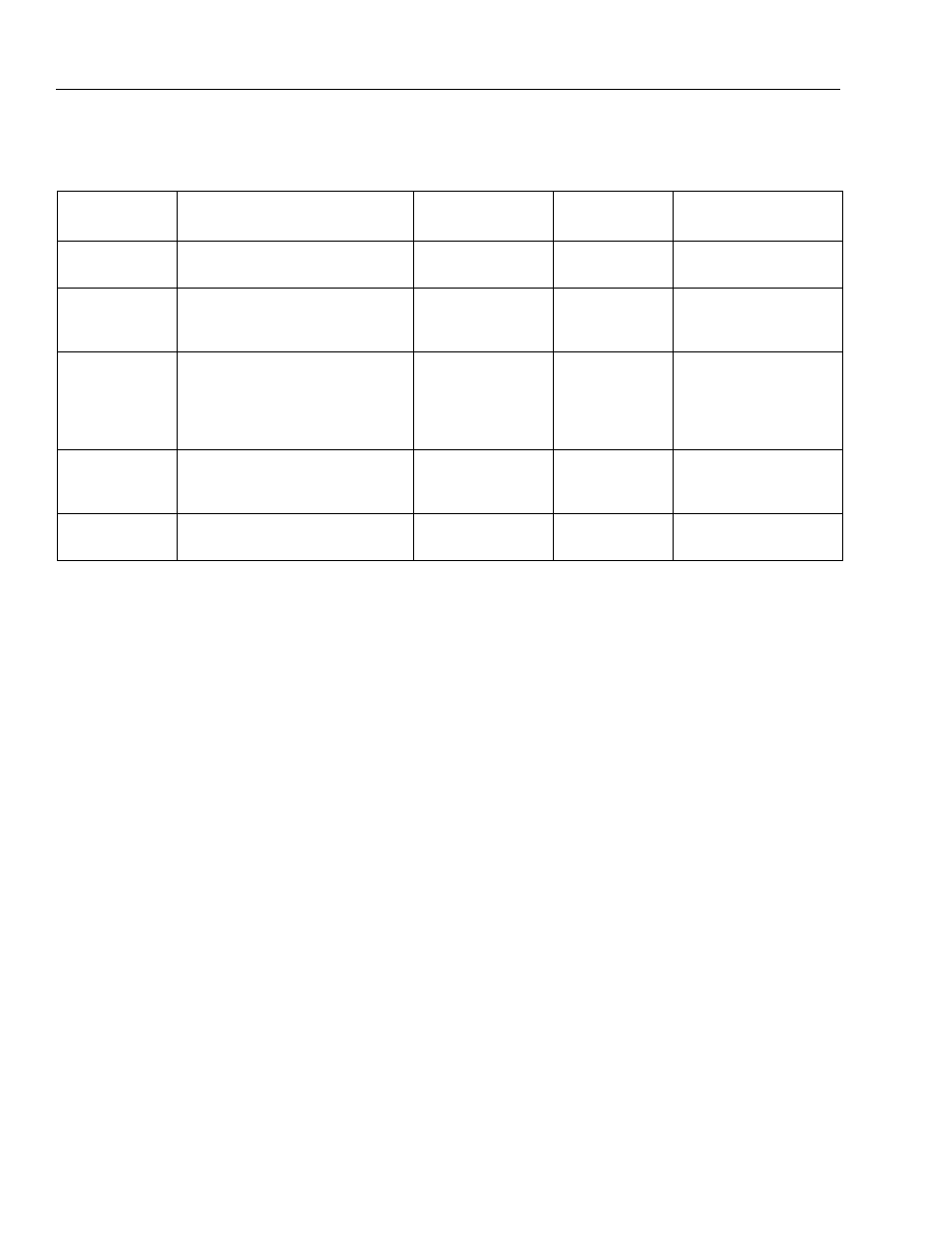

Table 2-1. Inspection and Maintenance

Type

Frequency

Primary

Responsibility

Service

Qualification

Reference

Pre-Start Inspection

Prior to use each day; or

At each Operator change.

User or Operator

User or Operator

Operator and Safety Manual

Pre-Delivery

Inspection

Prior to each sale, lease, or

rental delivery.

Owner, Dealer, or User

Qualified JLG

Mechanic

Service and Maintenance

Manual and applicable JLG

inspection form.

Frequent Inspection

In service for 3 months or 150 hours, which-

ever comes first; or

Out of service for a period of more than 3

months; or

Purchased used.

Owner, Dealer, or User

Qualified JLG

Mechanic

Service and Maintenance

Manual and applicable JLG

inspection form.

Annual Machine

Inspection

Annually, no later than 13 months from the

date of the prior inspection.

Owner, Dealer, or User

Factory-Certified

Service Technician

Service and Maintenance

Manual and applicable JLG

inspection form.

Preventative

Maintenance

At intervals as specified in the Service and

Maintenance Manual.

Owner, Dealer, or User

Qualified JLG

Mechanic

Service and Maintenance

Manual