4 cylinder drift test, Platform drift, Cylinder drift – JLG 450A_AJ Series II Service Manual User Manual

Page 41: 5 pins and composite bearing repair guidelines, Cylinder drift test -5, Platform drift -5 cylinder drift -5, Pins and composite bearing repair guidelines -5, Cylinder drift -5

SECTION 2 - GENERAL

3121180

– JLG Lift –

2-5

2.4 CYLINDER DRIFT TEST

Measure maximum acceptable cylinder drift using the fol-

lowing methods.

Platform Drift

Measure platform to ground drift. Lower booms (if

equipped) slightly elevated, upper boom fully extended

with rated load in the platform and power off. Maximum

allowable drift is 2" (5 cm) in 10 minutes. If machine does

not pass this test, proceed with the following:

Cylinder Drift

Drift is to be measured at cylinder rod with a calibrated

dial indicator. Cylinder oil must be at ambient temperature

and temperature stabilized.

Cylinder must have normal platform load applied.

If cylinder passes this test, it is acceptable.

NOTE: This information based on 6 drops per minute cylinder

leakage.

2.5 PINS AND COMPOSITE BEARING

REPAIR GUIDELINES

Filament wound bearings.

1. Pinned joints should be disassembled and

inspected if the following occurs:

a. Excessive sloppiness in joints.

b. Noise originating from joint during operation.

2. Filament wound bearings should be replaced if any

of the following is observed:

a. Frayed or separated fibers on liner surface.

b. Cracked or damaged liner backing.

c. Bearings that have moved or spun in their housing.

d. Debris embedded in liner surface.

3. Pins should be replaced if any of the following is

observed (pin should be properly cleaned prior to

inspection):

a. Detectable wear in bearing area.

b. Flaking, pealing, scoring, or scratches on pin

surface.

c. Rusting of pin in bearing area.

4. Re-assembly of pinned joints using filament wound

bearings.

a. Housing should be blown out to remove all dirt

and debris. Bearings and bearing housings

must be free of all contamination.

b. Clean bearing/pins with a solvent to remove all

grease and oil. Filament wound bearing are a

dry joint and should not be lubricated.

c. Inspect pin to ensure it is free of burrs, nicks,

and scratches which would damage bearing

during installation and operation.

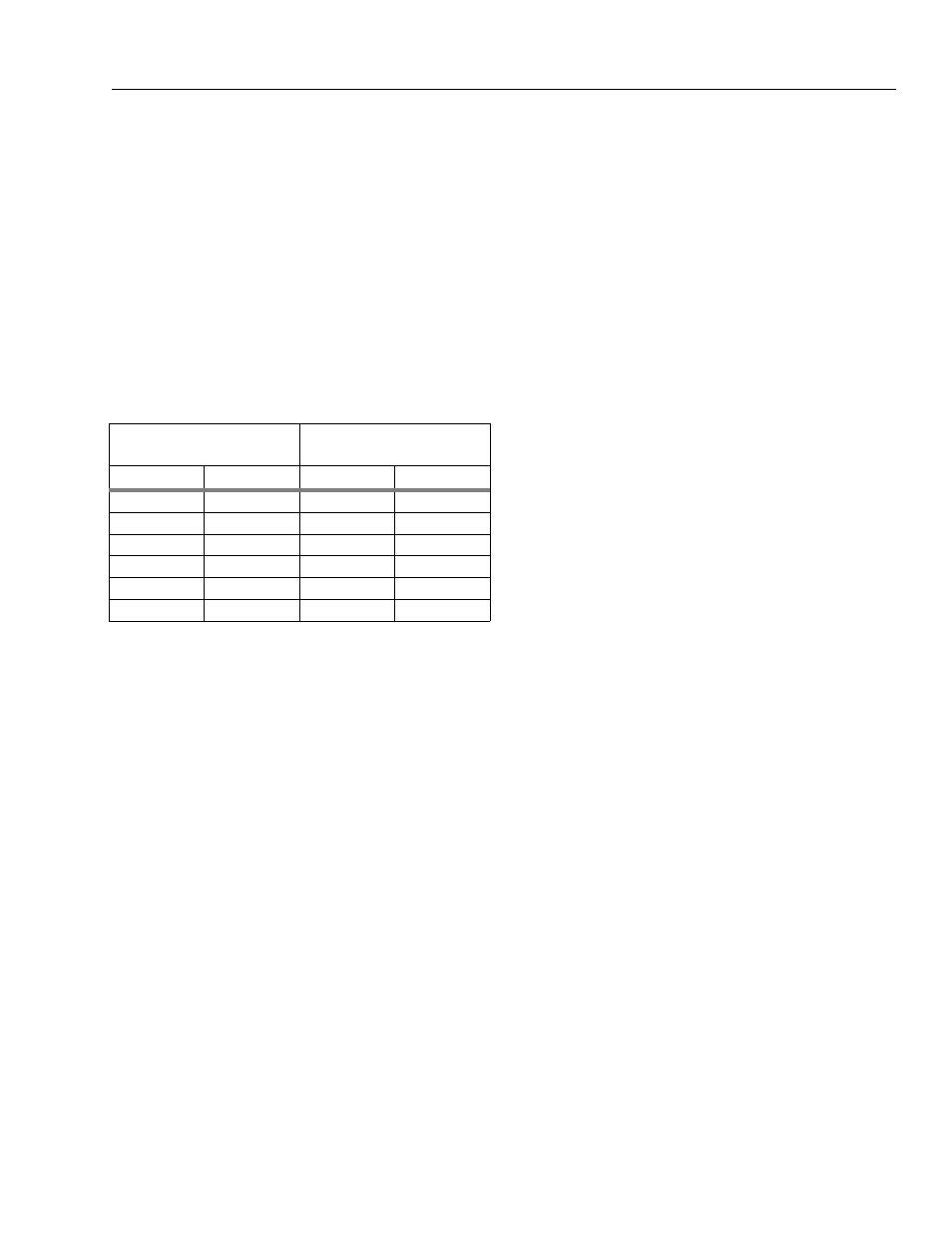

Table 2-2. Cylinder Drift

Cylinder Bore Diameter

Max. Acceptable Drift

in 10 Minutes

inches

mm

inches

mm

3

76.2

0.026

0.66

3.5

89

0.019

0.48

4

101.6

0.015

0.38

5

127

0.009

0.22

6

152.4

0.006

0.15

7

177.8

0.005

0.13