Spindle-brake sub-assembly, Spindle-brake sub-assembly -14 – JLG 450A_AJ Series II Service Manual User Manual

Page 64

SECTION 3 - CHASSIS & TURNTABLE

3-14

– JLG Lift –

3121180

Spindle-Brake Sub-Assembly

UNCONTROLLED OBJECTS CAN CAUSE EYE DAMAGE OR SERI-

OUS INJURY. ALWAYS WEAR EYE PROTECTION.

This procedure applies only to units with integral input

brake (2).

NOTE: For this procedure, use Brake Assembly Drawing,

which shows proper balloon numbers for individual

brake components. In the following instructions, if

the number has a “-” between two numbers, it refers

to Brake Assembly Drawing only and NOT Torque

Hub Assembly Drawing.

NOTE: The Koenig Expander Pressure Plug (12) requires a

special installation tool. It is not recommended to

remove this plug unless it is leaking. The installation

tool is available from KVT Solutioneering Group

(http://www.kvt-koenig.us) or their distributors as of

the date of this manual.

1. Install Pressure Plug (12) into Spindle (1A) using the

following procedure:

• Clean hole in spindle using appropriate Loctite spray

• Dip collar of plug in Loctite 290 or 680 (keep

unplugged portion of hole free of Loctite)

• Using appropriate tool, install plug flush with surface of

spindle

2. Place Spindle (1A) with splined end facing down.

Using appropriate tool (See back of manual), install

Retaining Ring (2-1) into spindle groove within

splines.

3. Place Washer (2-10) on top of Retaining Ring (2-1).

4. Place Stator (2-9) on top of Washer (2-10).

5. Place Rotor (2-12) on top of Stator (2-9).

6. Repeat steps 3 & 4 until there are a total of 8 Stators (2-9)

and 7 Rotors (2-12) installed.

7. Place Piston (2-8) with smaller O.D. end facing up.

8. Grease large Backup Ring (2-3) and install in large-

diameter groove at bottom of Piston (2-8).

9. Grease large O-Ring (2-2) and install in large diame-

ter groove at bottom of Piston (2-8), on top of large

Backup Ring (2-3).

10. Grease small O-Ring (2-5) and install in small diame-

ter groove near top of Piston (2-8). Make sure O-

Ring is seated in bottom of groove.

11. Grease small Backup Ring (2-4) and install in small

diameter groove near top of Piston (2-8), on top of

small O-Ring (2-5).

NOTE: If piston comes pre-assembled with shipping bolts

(2-11), skip to Step 15.

12. Insert Piston (2-8) into Spindle (1A) until it contacts

Stator (2-9).

13. Insert appropriate number of Springs (2-13) into Pis-

ton (2-8) counterbore. Use brake spring chart below

and a bill of materials for your particular model num-

ber to determine number of springs.

14. Place Pressure Plate (2-7) on top of Springs (2-13).

15. Using snap ring pliers, install Retaining Ring (2-6)

into groove in Spindle (1A) and on top of Pressure

Plate (2-7). Make sure Retaining Ring (2-6) is seated

properly in groove.

16. Remove Shipping Bolts (2-11) in brake pressure plate

to release springs in brake. Before removing bolts,

use Coupling (9 - Figure 3-11.) to center and align

Brake Rotors (2-12) with Spindle (1A).

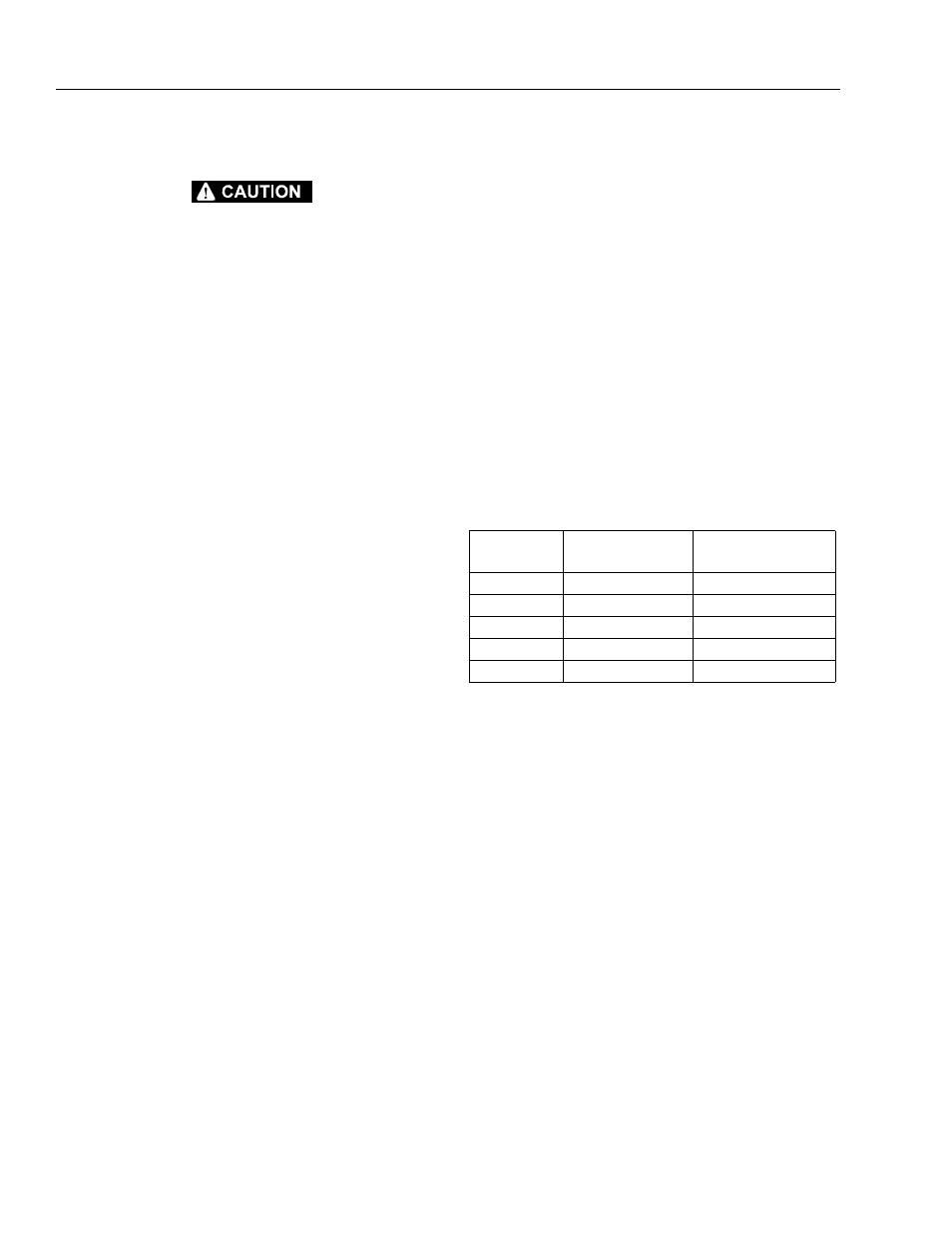

BRAKE

CODE

BRAKE P/N

NUMBER

OF SPRINGS

A

902337

12

B

902341

10

C

902342

8

D

902343

6

E

902345

9