24 diagnostic trouble code fault descriptions, Dtc 116- ect higher than expected stage 1, Diagnostic trouble code fault descriptions -162 – JLG 450A_AJ Series II Service Manual User Manual

Page 212: Dtc 116- ect higher than expected stage 1 -162, 103. clear faults prompt -162, Figure 3-103

SECTION 3 - CHASSIS & TURNTABLE

3-162

– JLG Lift –

3121180

3.24 DIAGNOSTIC TROUBLE CODE FAULT

DESCRIPTIONS

DTC 116- ECT Higher Than Expected Stage 1

• Engine Coolant Temperature Sensor.

• Check Condition-Engine Running.

• Fault Condition-Engine Coolant Temperature reading

or estimate greater than stage 1 limit when operating at

a speed greater than defined in diagnostic calibration.

• Corrective Action(s): Sound audible warning or illumi-

nate secondary warning lamp, disable adaptive learn

fueling correction during active fault. Recommend a

power derate 1/2 and/or a low rev limit to protect

engine from possible damage.

• Non-emissions related fault.

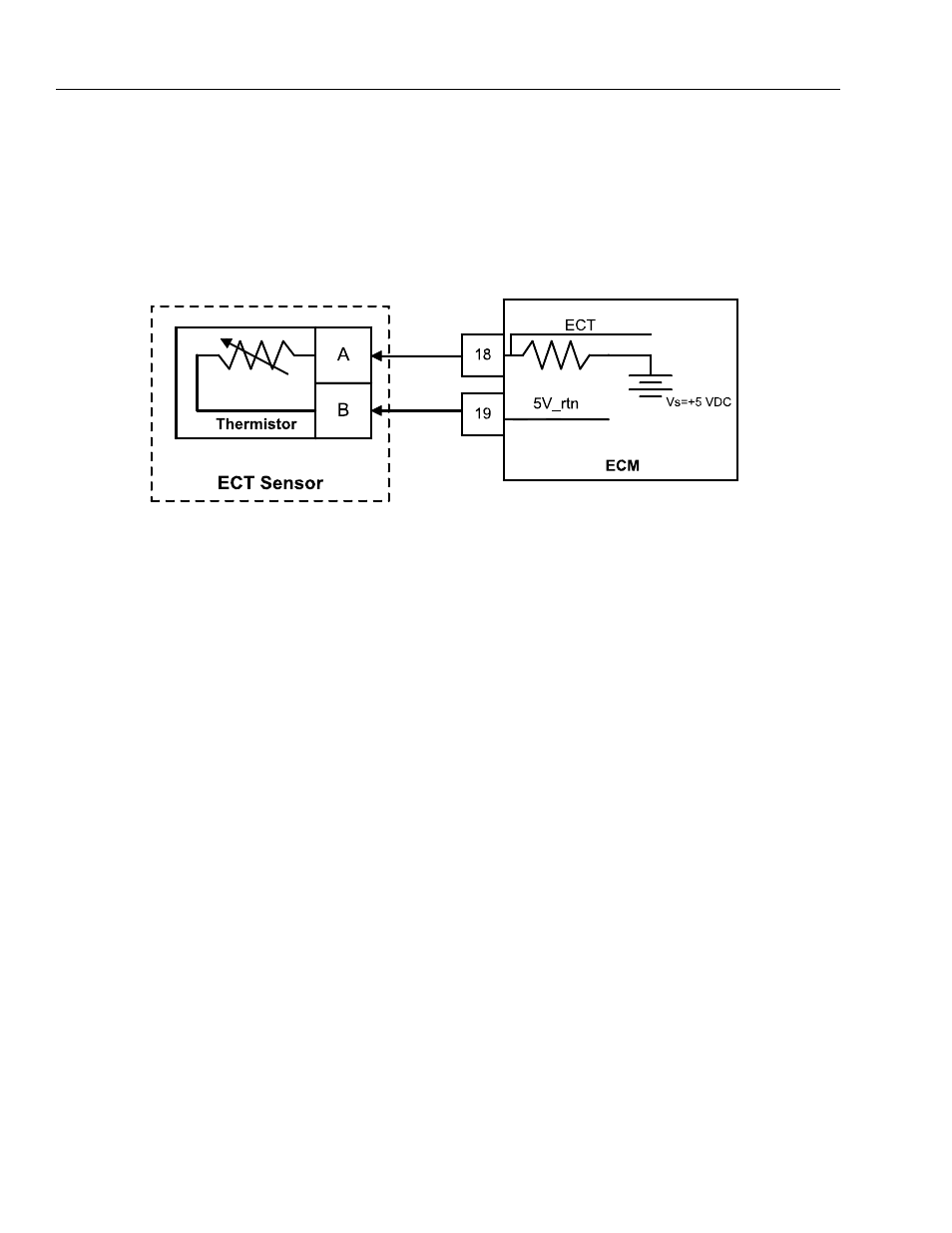

The Engine Coolant Temperature sensor is a thermistor

(temperature sensitive resistor) located in engine coolant.

Some engines use a CHT sensor located in cylinder head

coolant. Some engines use an ECT (Engine Coolant Tem-

perature) sensor located in coolant near the thermostat. If

engine is equipped with a CHT sensor, the ECT value is

estimated. If equipped with an ECT sensor, the CHT value

is estimated. They are used for engine airflow calculation,

ignition timing control, to enable certain features, and for

engine protection. The ECM provides a voltage divider cir-

cuit. The sensor reads higher voltage when cold and

lower when warm.

This fault helps protect engine in the event of over temper-

ature. When coolant exceeds x deg. F and engine RPM

exceeds y RPM for the latch time this fault will set.

Diagnostic Aids

If “ECT High Voltage” fault is also present, follow trouble-

shooting procedures for that fault as it may have caused

“ECT Higher Than Expected 1.”

Cooling system with air-to-water heat exchanger (radiator)

and fan:

• Check radiator has a proper amount of ethylene glycol/

water and is not leaking.

• Ensure there is no trapped air in cooling path.

• Inspect cooling system (radiator and hoses) for cracks

and connections are leak free.

• Check fan is operating properly.

• Check thermostat is not stuck closed.

Cooling system with water-to-water heat exchanger:

• Check heat exchanger has proper amount of ethylene

glycol/water and that the heat exchanger is not leaking.

• Ensure there is no trapped air in the cooling path.

• Inspect cooling system (radiator and hoses) for cracks

and connections are leak free.

• Check raw water pickup is not blocked/restricted by

debris and hose is tightly connected.

• Check thermostat is not stuck closed.

• Check raw water pump/impeller is intact and not

restricted.

Figure 3-103. Clear Faults Prompt