Turntable bearing mounting bolt condition check, Check frame to bearing bolts, Swing bearing torque sequence -70 – JLG 450A_AJ Series II Service Manual User Manual

Page 120: Swing bearing feeler gauge check -70

SECTION 3 - CHASSIS & TURNTABLE

3-70

– JLG Lift –

3121180

IF COMPRESSED AIR OR ELECTRICALLY OPERATED IMPACT

WRENCH IS USED TO TIGHTEN BEARING ATTACHMENT BOLTS,

CHECK TORQUE SETTING ACCURACY OF TOOL BEFORE USE.

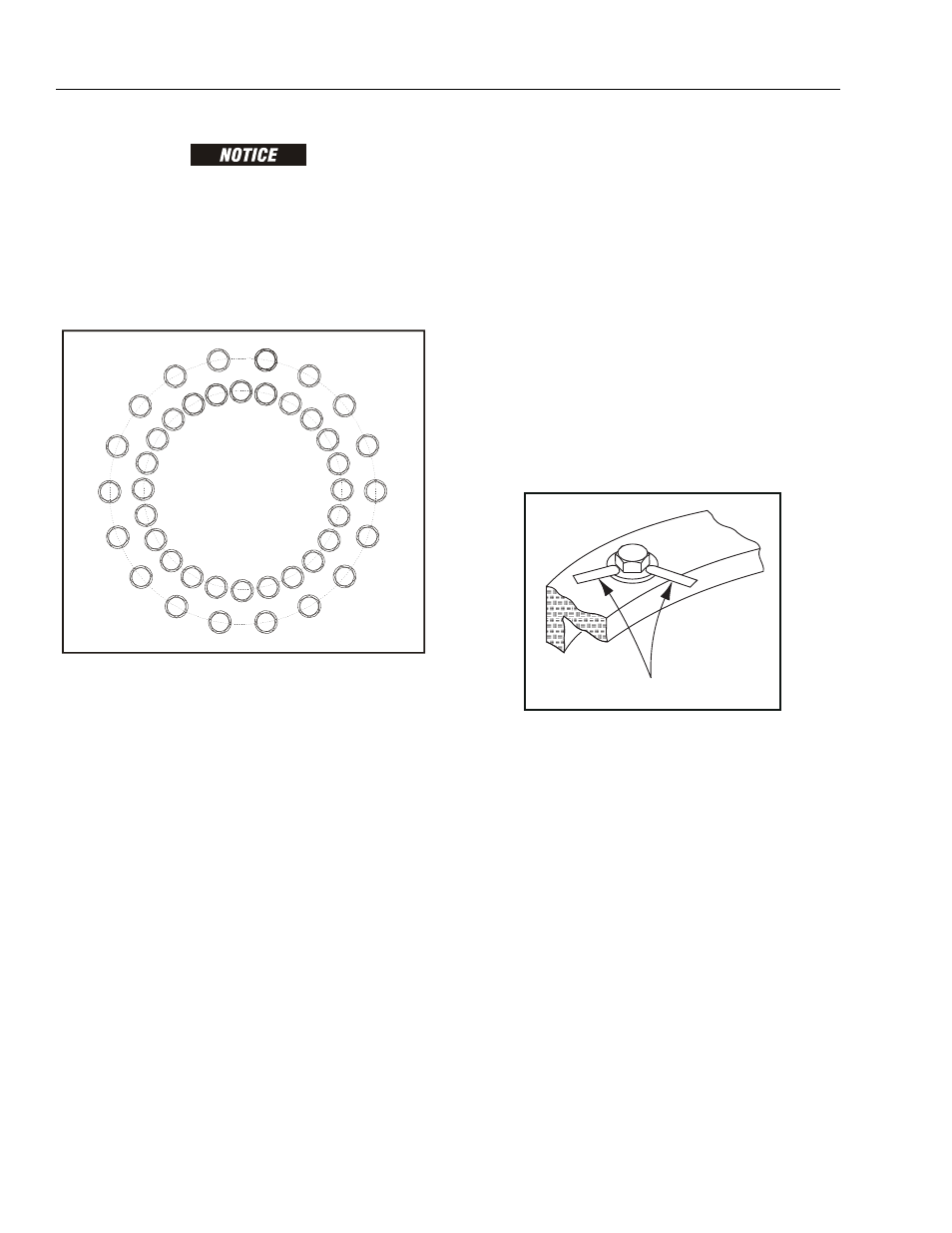

7. Tighten bolts to an initial torque of 130 ft-lb (176 Nm)

following torque sequence shown in Figure 3-50.,

Swing Bearing Torque Sequence. Tighten to a final

torque of 190 ft-lb (257 Nm) following same

sequence.

8. Remove lifting equipment from bearing.

9. Use suitable lift equipment to carefully position turn-

table assembly above machine frame.

10. Carefully lower turntable onto swing bearing. Ensure

scribed line of inner race of bearing aligns with

scribed mark on turntable. If a new swing bearing is

used, ensure filler plug fitting is at 90 degrees from

fore and aft centerline of turntable.

11. Apply a light coating of Loctite 271 to new bearing

bolts and install through turntable and inner race of

bearing.

12. Tighten bolts to an initial torque of 130 ft-lb (176 Nm)

following torque sequence shown in Figure 3-52.

Tighten to a final torque of 190 ft-lb (257 Nm) follow-

ing same sequence.

13. Remove lift equipment.

14. Route hydraulic lines through center of turntable and

frame. Connect as tagged prior to removal.

15. Following all applicable safety precautions, activate

hydraulic system and functionally check swing sys-

tem for proper and safe operation.

Turntable Bearing Mounting Bolt Condition

Check

NOTE: This check is designed to replace existing bearing

bolt torque checks on JLG Lifts in service. This

check must be performed after first 50 hours of

machine operation and every 600 hours of machine

operation thereafter. Replace missing or loose bolts

with new bolts and torque to value specified in

torque chart after lubricating bolt threads with Loctite

#271. After replacing and re-torquing bolt or bolts,

recheck all existing bolts for looseness.

Check Frame To Bearing Bolts

1. Fully retracted boom and elevate to 70 degrees (full

elevation).

2. Try and insert a 0.0015" feeler gauge between bolt

head and hardened washer at positions shown in

Figure 3-51., Swing Bearing Feeler Gauge Check.

3. Ensure 0.0015" feeler gauge will not fit under bolt

head to bolt shank.

4. Swing turntable 90 degrees, and check some

selected bolts at the new position.

5. Continue rotating turntable at 90 degrees intervals

until a sampling of bolts have been checked in all

quadrants.

3

7

21

17

13

9

5

1

24

20

16

12

22

18

14

10

6

2

23

19

15

11

8

4

17

13

9

5

1

16

12

18

14

10

6

2

15

7

3

11

8

4

Figure 3-50. Swing Bearing Torque Sequence

.0015" Feeler Gauge

Figure 3-51. Swing Bearing Feeler Gauge Check