16 arms and platform positioning and support, Arms and platform positioning and support -62, Tilt sensor removal -62 – JLG 3246ES Service Manual User Manual

Page 98: Tilt sensor harness for 4000021 -62, Tilt sensor harness for 1001114936 -62

SECTION 3 - CHASSIS & SCISSOR ARMS

3-62

– JLG Lift –

3121166

3.16

ARMS AND PLATFORM POSITIONING AND

SUPPORT

CAUTION

PLATFORM IS HEAVY AND PRESENTS A CRUSHING HAZARD.

TAKE GREAT CARE WHEN REMOVING PLATFORM OR SCISSOR

ARM ASSEMBLY

The arm stack can be supported by using an overhead

crane,(See Figure 3-47.). If an overhead crane is not

available the stack may also be lifted by using a fork-

truck using the following instructions:

1.

With the forks on the forktruck slid close together,

enter from the front of the machine and place the

forks on the cross tube of the second arm weld-

ment below the platform.

2.

Slowly lift the arm stack with the forktruck while

the manual descent valve is being engaged (this

allows the oil to drain back into the tank).

3.

Place machine on safety prop and leave the fork-

truck in place.

4.

At this point the lift cylinder removal may begin.

(Refer to Section 4.6, Lift Cylinder Removal)

If removal of the platform becomes necessary use the

above procedure to stabilize the platform for pin and

platform removal.

3

1

4

2

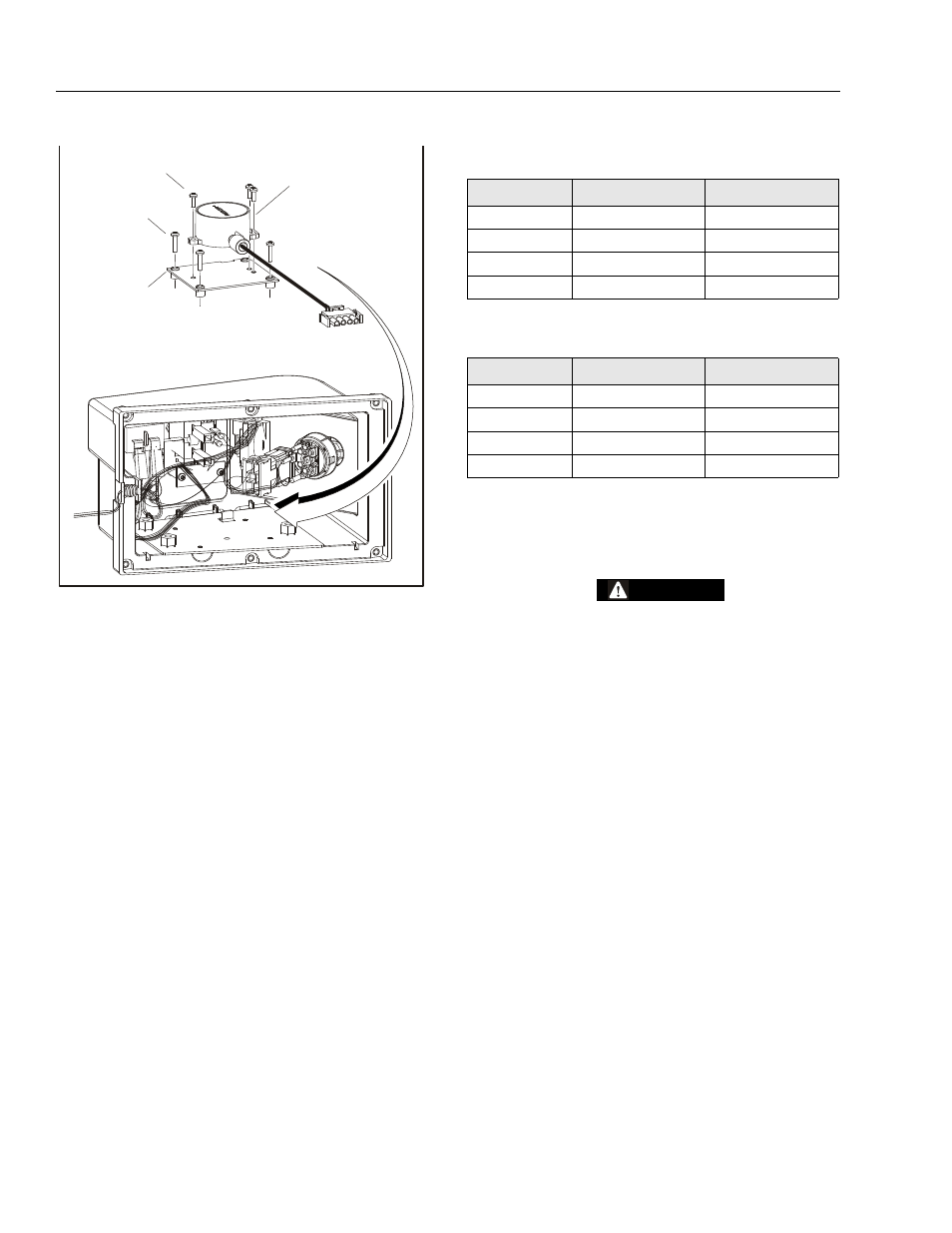

1.

Tilt Sensor (JLG P/N 4000021

or

1001114936)

2.

Sensor Mount

3.

Screw, 3.5 x 0.6 x 16 LG

4.

Screw, 3.5 x 0.6 x 10 LG

Figure 3-46. Tilt Sensor Removal

Table 3-7. Tilt Sensor Harness for 4000021

Wire Color

Function

Connector Pin

Red

VCC

1

Green

PWMX

2

White

PWMY

3

Black

Ground

4

Table 3-8. Tilt Sensor Harness for 1001114936

Wire Color

Function

Connector Pin

Red

VCC

1

White

CANH

2

Green

CANL

3

Black

Ground

4