0 help comments – JLG 3246ES Service Manual User Manual

Page 157

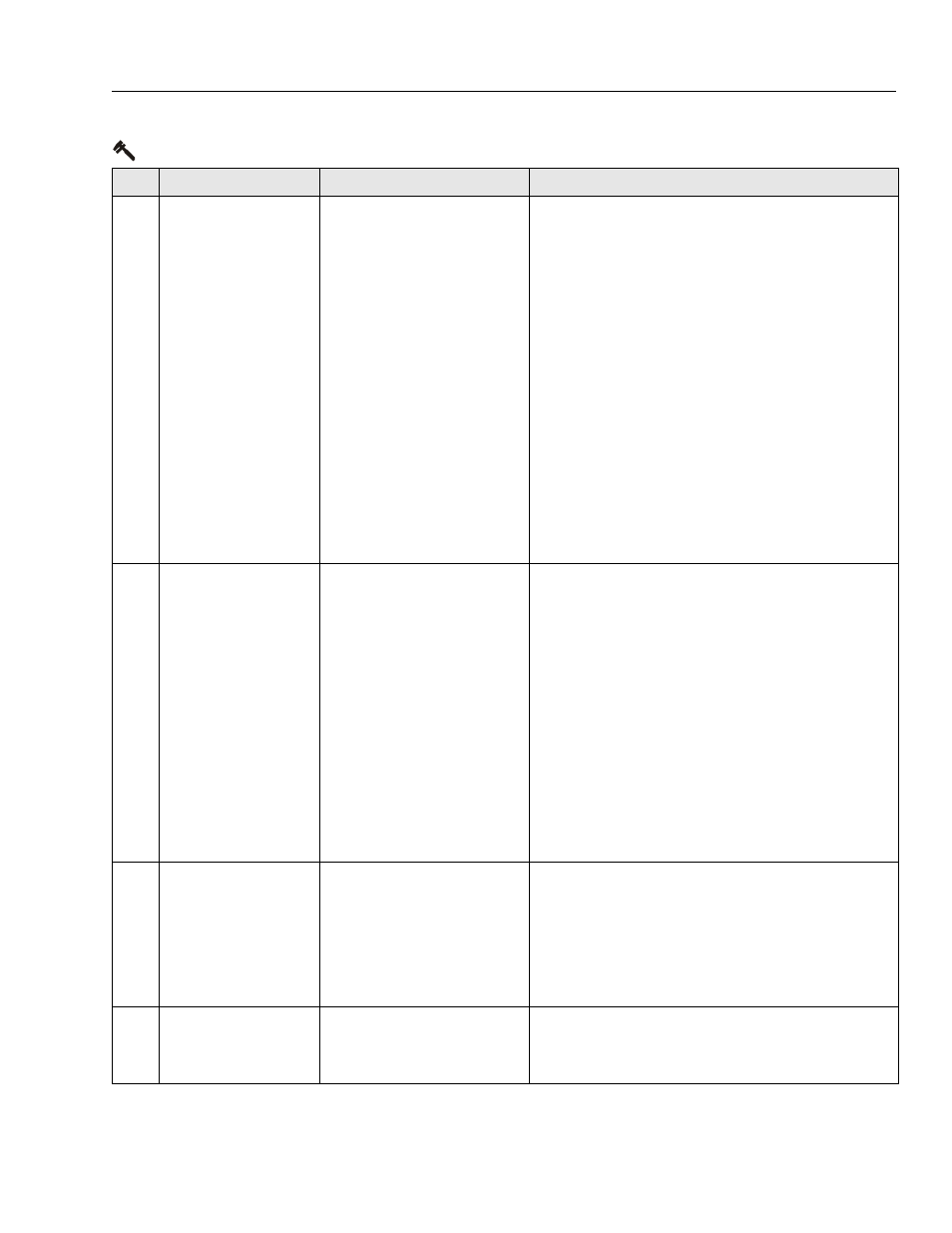

SECTION 6 - DIAGNOSTIC TROUBLE CODES

3121166

– JLG Lift –

6-5

005

DRIVE & LIFT UP PRE-

VENTED - TILTED & ELE-

VATED

Driving is not possible since the

platform is elevated and the

chassis is not level.

• Check that the machine is tilted. If so, lower the plat-

form and reposition the machine to a level surface.

• Fully stow the platform.

• The tilt sensor is part of the ground control box. Check

that the ground control box is secured to the

machine.

• Check that the pothole protection switches are

securely mounted.

• Check that the elevation angle sensor is securely

mounted.

• Check the ANALYZER -> MACHINE SETUP -> MARKET

configuration.

• If MARKET is set to CE, ensure ANALYZER -> MACHINE

SETUP -> TILT CUTOUT parameter is set as desired.

• Check pothole protection switch adjustment.

• Backprobing ground board J1-18 should show about

0 volts.

• Backprobing ground board J1-10 should show about

0 volts.

• Calibrate the elevation sensor, see Section 5.5.

• Calibrate the tilt sensor, see Section 5.2.

006

LIFT UP PREVENTED -

MAX HEIGHT ZONE A

The vehicle has reached the

maximum height and further lift

up motion is not possible. Appli-

cable to 2630ES or 3246ES.

• Check that the zone is set appropriately for the plat-

form load.

• Check that the platform height is at the rated maxi-

mum height specification (20’ for 2630 or 26’ for the

3246).

• Check that the elevation angle sensor is securely

mounted.

• If there are any elevation sensor faults (DTC 251, 252,

2511, or 2512), troubleshoot those first.

• Check that ANALYZER -> MACHINE SETUP -> MODEL

setting is correct.

• Check that ANALYZER -> MACHINE SETUP -> MARKET

setting is correct.

• Check ANALYZER -> DIAGNOSTICS -> ELEV SENSOR ->

ZEROED is about 1.53V for the 3246 or about 1.22V for

the 2630 when at full height. If not, repair or replace

the elevation angle sensor.

007

DRIVING AT CUTBACK -

POTHOLE STILL

ENGAGED

While stowed, drive speed is

reduced since the control sys-

tem detected that the pot-hole

protection mechanism failed to

retract.

• Check for obstructions around the pot-hole protec-

tion mechanisms.

• Check that the PHP switches are securely mounted.

• Check PHP switches wiring from the ground board

and for proper operation. The left PHP input (24V) is

from J1-9 and its output (24V when deployed) is to J1-

10. The right PHP input (24V) is from J1-17 and its

output (24V when deployed) is to J1-18.

008

FUNCTIONS LOCKED

OUT - SYSTEM POW-

ERED DOWN

After 2 hours without activity,

the control system enters a low-

power state to preserve battery

charge.

• Normal operation should resume after a power cycle.

• Check batteries charge, condition, etc.

0-0 Help Comments

DTC

FAULT MESSAGE

DESCRIPTION

CHECK