Spindle disassembly, Spindle disassembly -15 – JLG 3246ES Service Manual User Manual

Page 51

SECTION 3 - CHASSIS & SCISSOR ARMS

3121166

– JLG Lift –

3-15

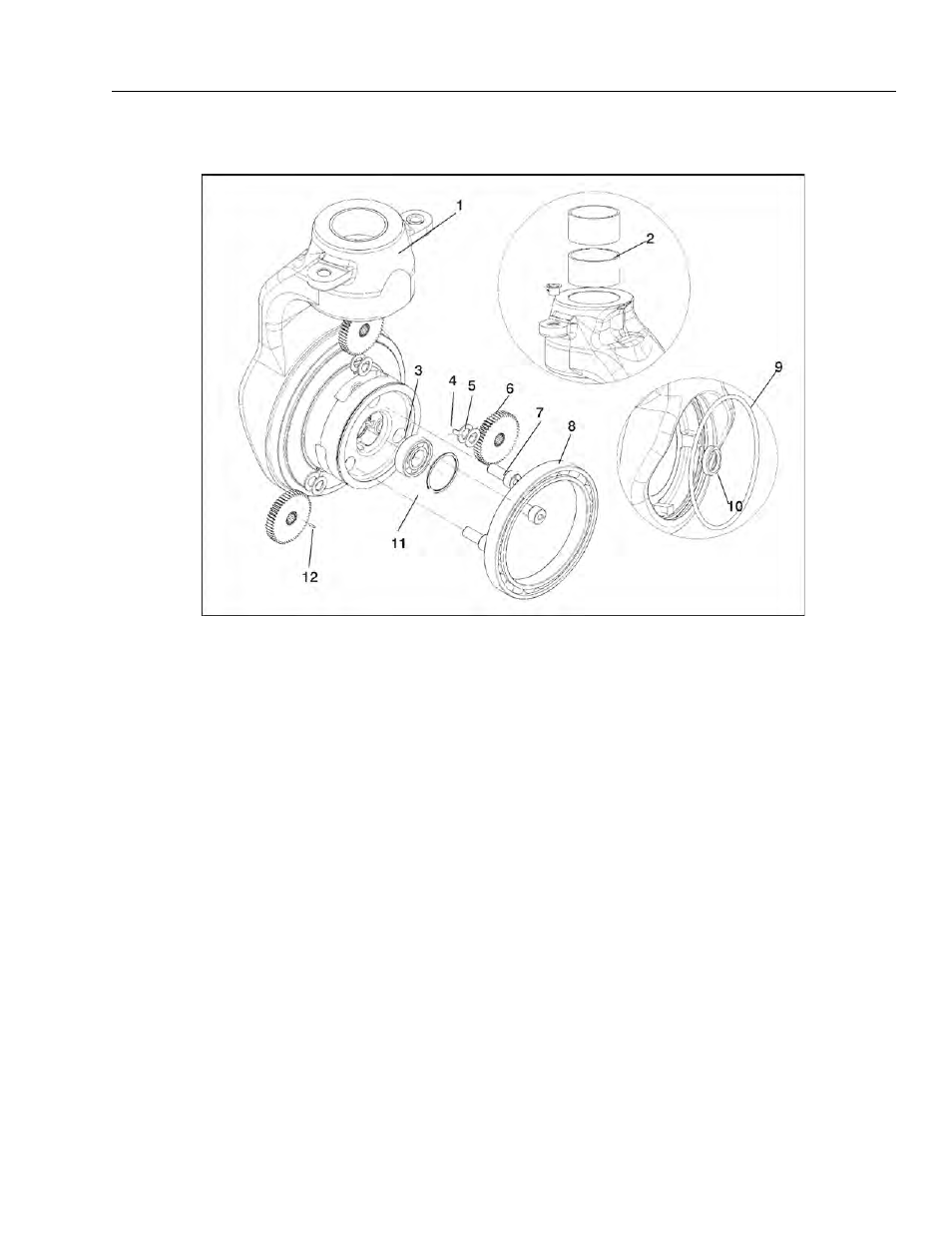

Spindle Disassembly

1.

Place unit on bench with planet gears facing up.

2.

Remove 3 output planet shafts.

NOTE: These planet shafts are held in with a press fit. Use

the tapped hole in the end of the pin in conjunction

with a slide hammer or similar tool to remove them.

3.

Remove the output planet gear, thrust washer, and

tanged washer out of each gear “window” of the

spindle.

NOTE: The output planet gears are a very similar size to the

input planet gears, tag or label the planet gears to

avoid confusion.

4.

Using a screwdriver remove the shaft bearing snap

ring.

5.

Remove the shaft ball bearing from the center

bore.

6.

Press out the motor shaft seal from the center

bore.

7.

Remove the main bearing from the outside diame-

ter of the spindle.

NOTE: This bearing is held in with a press fit. You will need to

pry against the spindle to remove it. The bearing will

need to be replaced when this is done.

8.

Press out the main bushings at the top of the spin-

dle neck.

9.

Remove the motor O’ring from the groove on side

opposite from the carrier side.

1.

Spindle Sub-Assembly

2.

Main Bushing

3.

Shaft Ball Bearing

4.

Tanged Washer

5.

Thrust Washer

6.

Output Planet Gear

7.

Output Planet Pins

8.

Main Bearing

9.

O-Ring

10.

Shaft Seal

11.

Snap Ring

12.

Needle Roller Bearings

Figure 3-14. Spindle DIsassembly