3 cylinder checking procedure, 4 lift pressure setting procedure, Cylinder checking procedure -2 – JLG 3246ES Service Manual User Manual

Page 104: Lift pressure setting procedure -2, Lift pressure setting -2

SECTION 4 - HYDRAULICS

4-2

– JLG Lift –

3121166

4.3

CYLINDER CHECKING PROCEDURE

NOTE: Cylinder check must be performed anytime a system

component is replaced or when improper system

operation is suspected.

Cylinders Without Counterbalance Valves and

Steer Cylinder

1.

Using all applicable safety precautions, activate

pump motor and fully extend cylinder to be

checked.

2.

Carefully disconnect hydraulic hoses from retract

port of cylinder. There will be some initial weeping

of hydraulic fluid which can be caught in a suitable

container. After the initial discharge, there should

be no further drainage from the retract port.

3.

Activate pump motor and extend cylinder.

4.

If cylinder retract port leakage is less than 6-8

drops per minute, carefully reconnect hose to port

and retract cylinder. If leakage continues at a rate

of 6-8 drops per minute or more, cylinder repair

must be made.

5.

With cylinder fully retracted, shut down machine

power and carefully disconnect hydraulic hose

from cylinder extend port.

6.

Activate pump motor and retract cylinder. Check

extend port for leakage.

7.

If extend port leakage is less than 6-8 drops per

minute, carefully reconnect hose to extend port,

than activate cylinder through one complete cycle

and check for leaks. If leakage continues at a rate

of 6-8 drops per minute or more, cylinder repairs

must be made.

4.4

LIFT PRESSURE SETTING PROCEDURE

1.

Place 120% of the rated load of the machine on

the platform.

2.

Increase lift pressure to raise the platform and set

the safety prop.

3.

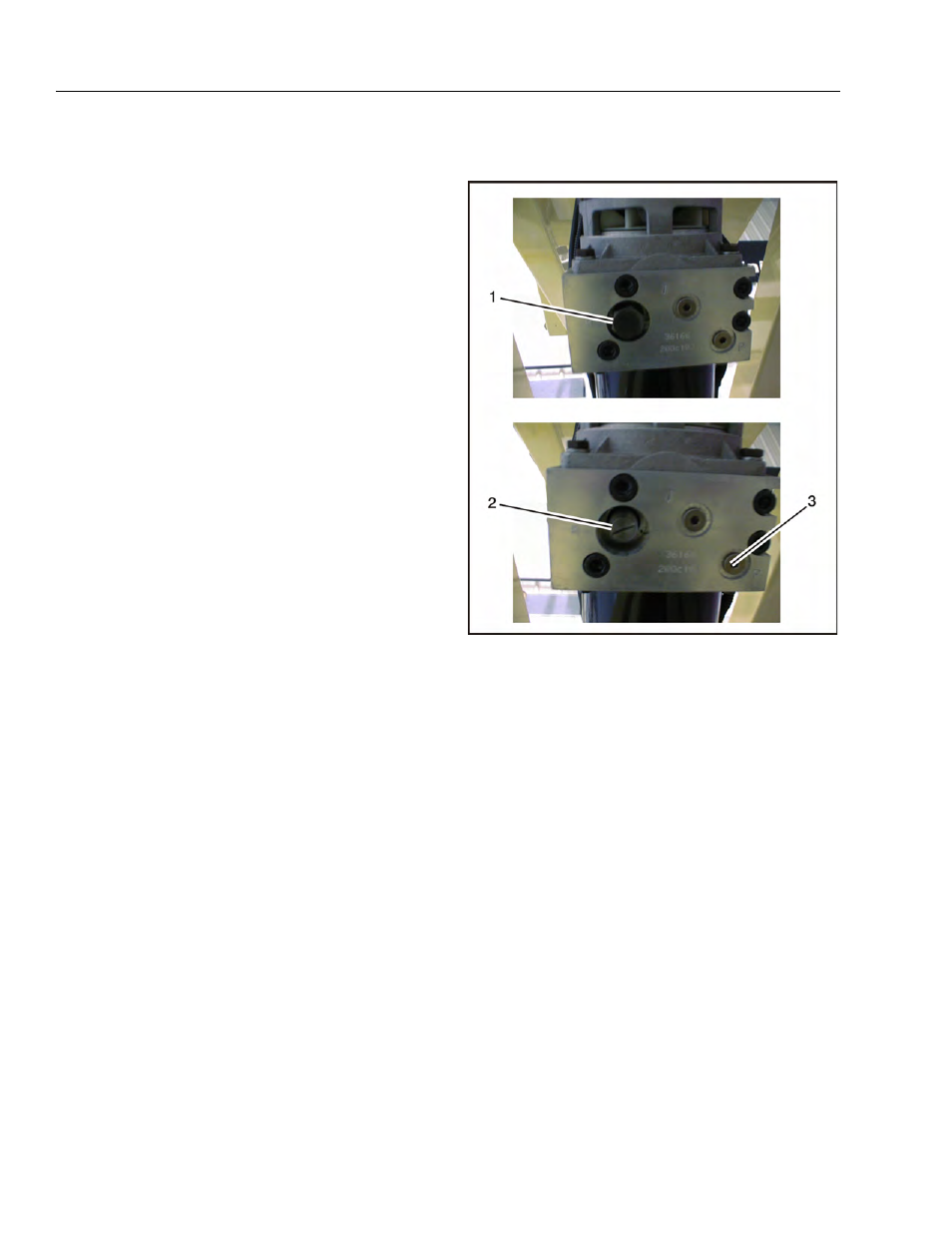

Locate the Large Nut (1) on the underside of the

valve block.

4.

Using a 7/8 in. wrench, remove the large nut (1).

This will expose the Pressure Setting Screw (2).

5.

Remove plug from P port (3) and install a pressure

gauge.

6.

Raise the platform and take a pressure reading.

7.

Adjust the Pressure Setting Screw to reach the

proper lift pressure per model as listed in Table 4-

1.

Figure 4-1. Lift Pressure Setting

1. Large Nut

2. Pressure Setting Screw

3. P port