Pump removal, Pump removal -8 – JLG 3246ES Service Manual User Manual

Page 110

SECTION 4 - HYDRAULICS

4-8

– JLG Lift –

3121166

persist (erratic PUMP PWM%, PUMP CUR around

150A), examine the cabling between the Pump

Motor and Power Module compartment for a

short-circuit (most likely near area where cylinder

retracts between frame side sheets or near pot-

hole mechanism). If the symptoms change, sus-

pect a short-circuited (or mechanically frozen)

pump motor.

A clamp-on ammeter (set for 200A DC) can be

placed on either Pump Motor Cable for verifica-

tion. During Lift Up, the ammeter will read

approximately 150A.

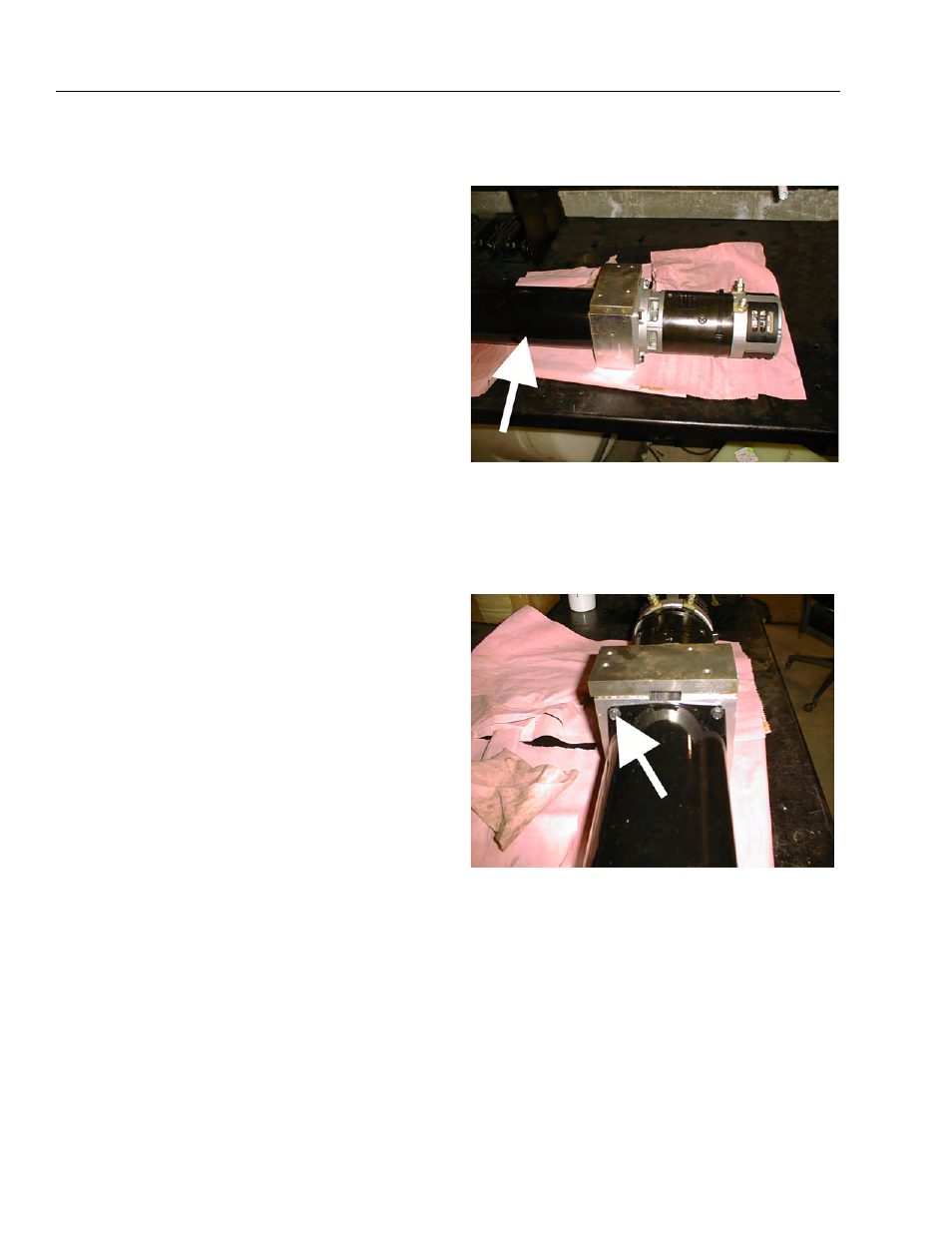

Pump Removal

1.

Place the pump/motor assembly on a clean work-

bench.

NOTE: Drain the hydraulic oil by carefully removing the oil

fill plug located on the left side of the hydraulic reser-

voir.

2.

Remove the oil tank from the lift cylinder as fol-

lows:

a. Slowly loosen and remove the four bolts that

hold the tank on to the cylinder.

b. Carefully remove the tank from the valve body

taking care not to damage internal pickup

tube or o-ring gasket on tank.

c. Place tank on a suitable work bench or work

area.

NOTE: The filter and bypass are located on the pickup tube

inside the tank.

The filter should be changed once a year.