Codes and standards, Step 1 — safety, Step 2 — general installation – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 6: Step 3 — combustion and ventilation air, Step 4 — duct systems, Step 5 — acoustical lining and fibrous glass duct, Step 6 — gas piping and gas pipe pressure testing

6

construction process must be either changed or thoroughly

cleaned prior to occupancy.

S

The furnace, ductwork and filters are cleaned as necessary to

remove drywall dust and construction debris from all HVAC

system components after construction is completed.

S

After construction is complete, verify furnace operating

conditions including ignition, input rate, temperature rise and

venting, according to the manufacturer’s instructions. If this

furnace is installed with a direct--vent (combustion air and flue)

system, a factory accessory termination kit must be installed. In a

direct--vent system, all air for combustion is taken directly from

the outside atmosphere. See furnace and factory accessory

termination kit instructions for proper installation.

S

These furnaces are shipped with the following materials to assist

in proper furnace installation. These materials are shipped in the

main blower compartment.

Installer Packet Includes:

Installation, Start---up, and Operating Instructions

Service and Maintenance Instructions

User’s Information Manual

Warranty Certificate

Loose Parts Bag includes:

Quantity

Pressure tube extension

1

Collector Box or condensate trap extension tube

1

Inducer Housing drain tube

1

1/2---in. (13 mm) CPVC street elbow

2

Drain tube coupling

1

Drain tube coupling grommet

1

Gas line grommet

1

Vent pipe grommet

1

Combustion---air pipe grommet

2

Gas line entry hole filler plug

1

Power entry hole filler plug

2

Condensate trap hole filler plug

3

Vent and combustion---air intake hole filler plug

2

Combustion---air pipe perforated disk assembly

1

S

The furnace shall be installed so that the electrical components

are protected from water.

S

For accessory installation details, refer to applicable installation

literature.

CODES AND STANDARDS

Follow all national and local codes and standards in addition to

these instructions. The installation must comply with regulations of

the serving gas supplier, local building, heating, plumbing, and

other codes. In absence of local codes, the installation must comply

with the national codes listed below and all authorities having

jurisdiction in Canada.

In the United States and Canada, follow all codes and standards for

the following:

Step 1 — Safety

S

US: National Fuel Gas Code (NFGC) NFPA 54--2006/ANSI

Z223.1--2006 and the Installation Standards, Warm Air Heating

and Air Conditioning Systems ANSI/NFPA 90B

S

CANADA: National Standard of Canada, Natural Gas and

Propane Installation Code (NSCNGPIC) CAN/CSA B149.1--05

Step 2 — General Installation

S

US: NFGC and the NFPA 90B. For copies, contact the National

Fire Protection Association Inc., Batterymarch Park, Quincy,

MA 02269; or for only the NFGC contact the American Gas

Association, 400 N. Capitol, N.W., Washington DC 20001

S

CANADA: NSCNGPIC. For a copy, contact Standard Sales,

CSA International, 178 Rexdale Boulevard,

Step 3 — Combustion and Ventilation Air

S

NFPA 54--2006/ANSI Z223.1--2006, Air for Combustion and

Ventilation

S

CANADA: Part 8 of the NSCNGPIC CAN/CSA B149.1--05,

Venting Systems and Air Supply for Appliances

Step 4 — Duct Systems

S

US and CANADA: Air Conditioning Contractors Association

(ACCA) Manual D, Sheet Metal and Air Conditioning

Contractors National Association (SMACNA), or American

Society of Heating, Refrigeration, and Air Conditioning

Engineers (ASHRAE) 2005 Fundamentals Handbook Chapter

35.

Step 5 — Acoustical Lining and Fibrous Glass

Duct

S

US and CANADA: current edition of SMACNA, NFPA 90B as

tested by UL Standard 181 for Class I Rigid Air Ducts

Step 6 — Gas Piping and Gas Pipe Pressure

Testing

S

US: NFGC; chapters 5, 6, 7, and 8 and national plumbing codes

S

CANADA: NSCNGPIC Parts 4, 5, 6 and 9. In the state of

Massachusetts:

S

This product must be installed by a licensed plumber or gas

fitter.

S

When flexible connectors are used, the maximum length shall

not exceed 36 inches.

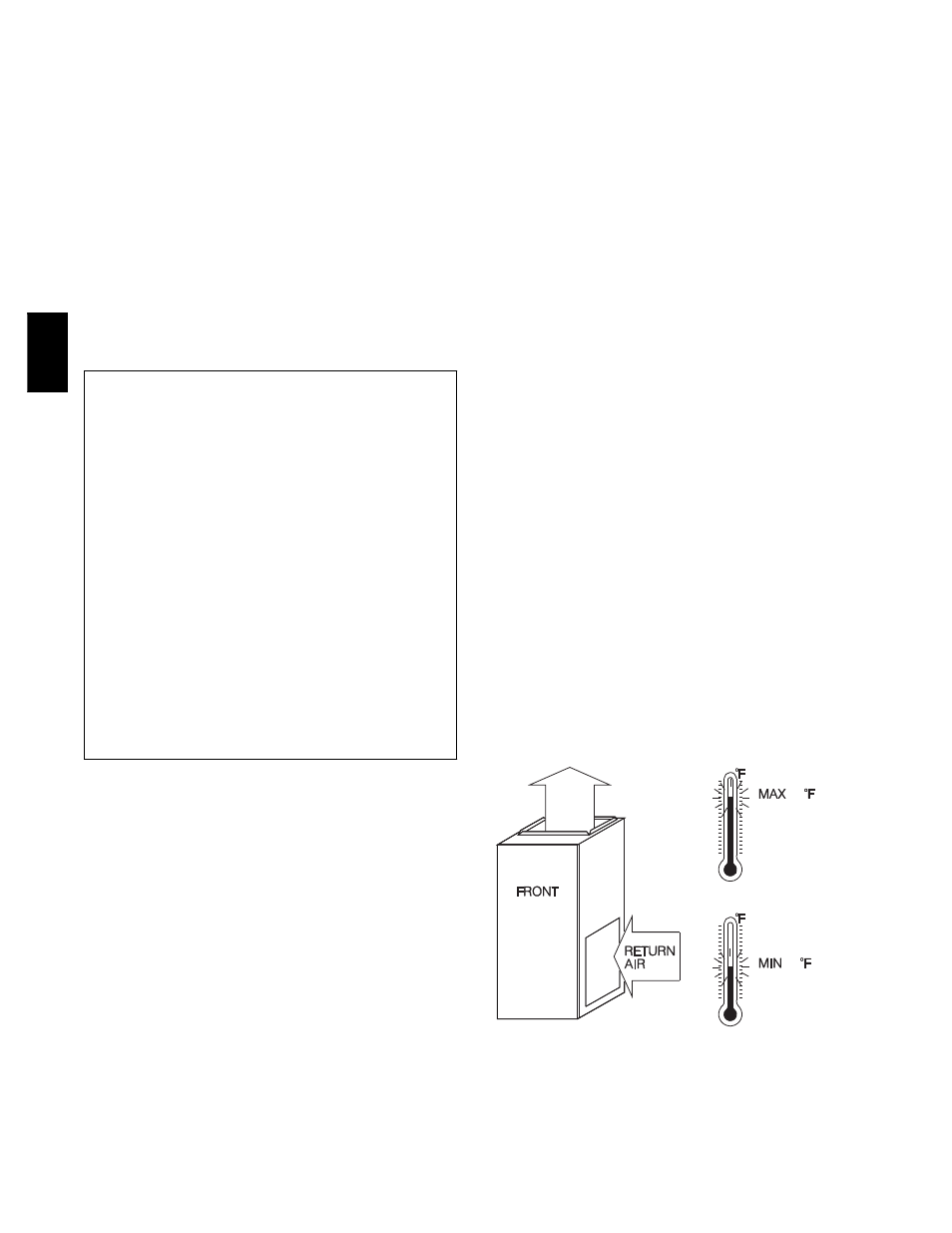

60

80

/ 27 C

/ 16 C

A06745

Fig. 4 -- Return--Air Temperature

355A