Installation, Combination of indoor and outdoor air, Step 1 — leveling legs (if desired) – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 20: 355a

20

1 SQ IN .

PER

4000

BTUH*

DUCTS

TO

O UTDOORS

1 SQ IN.

PER 4000

BTUH*

C

IRCULA

TING

AIR DUCTS

VENT

THR OUGH

R OOF

D

B

A

C

E

1 SQ IN.

PER 4000

BTUH*

DUCT

TO

OUTDOORS

CIRCULA TING AIR DUCT S

1 SQ IN.

PER 2000

BTUH*

1 SQ IN.

PER 2000

BTUH*

DUCT S

TO

OUTDOORS

12

″ MAX

12

″ MAX

12

″ MAX

12

″

MAX

12

″

MAX

OUTDOORS

1 SQ IN .

PER

4000

BTUH*

F

G

CLEARANCE IN FRONT

OF COMB

USTION AIR

OPENINGS SHALL BE

AT LEAST 3 IN

.

(305mm)

(305mm)

(305mm)

(305mm)

(305mm)

(76mm)

*Minimum dimensions of 3 in. (76 mm).

Use any of the following combinations of openings:

A & B C & D D & E F & G

A03174

Fig. 19 -- Air for Combustion, Ventilation, and Dilution for

Outdoors

When combustion air ducts are used, they must be of the same

cross sectional area as the free area of the openings to which they

connect. The minimum dimension of ducts must not be less than 3

in. (76 mm).

Combination of Indoor and Outdoor Air

1. Indoor openings shall compy with the Indoor Combustion

Air Method below and,

2. Outdoor openings shall be located as required in the

Outdoor Combustion Air Method mentioned previously

and,

3. Outdoor openings shall be sized as follows:

a. Calculate the Ratio of all Indoor Space volume divided

by required volume for Indoor Combustion Air

Method below.

b. Outdoor opening size reduction Factor is 1 minus the

Ratio in a. above.

c. Minimum size of Outdoor openings shall be the size

required in Outdoor Combustion Air Method above

multiplied by reduction Factor in b. above. The

minimum dimension of air openings shall be not less

than 3 in. (76 mm).

INSTALLATION

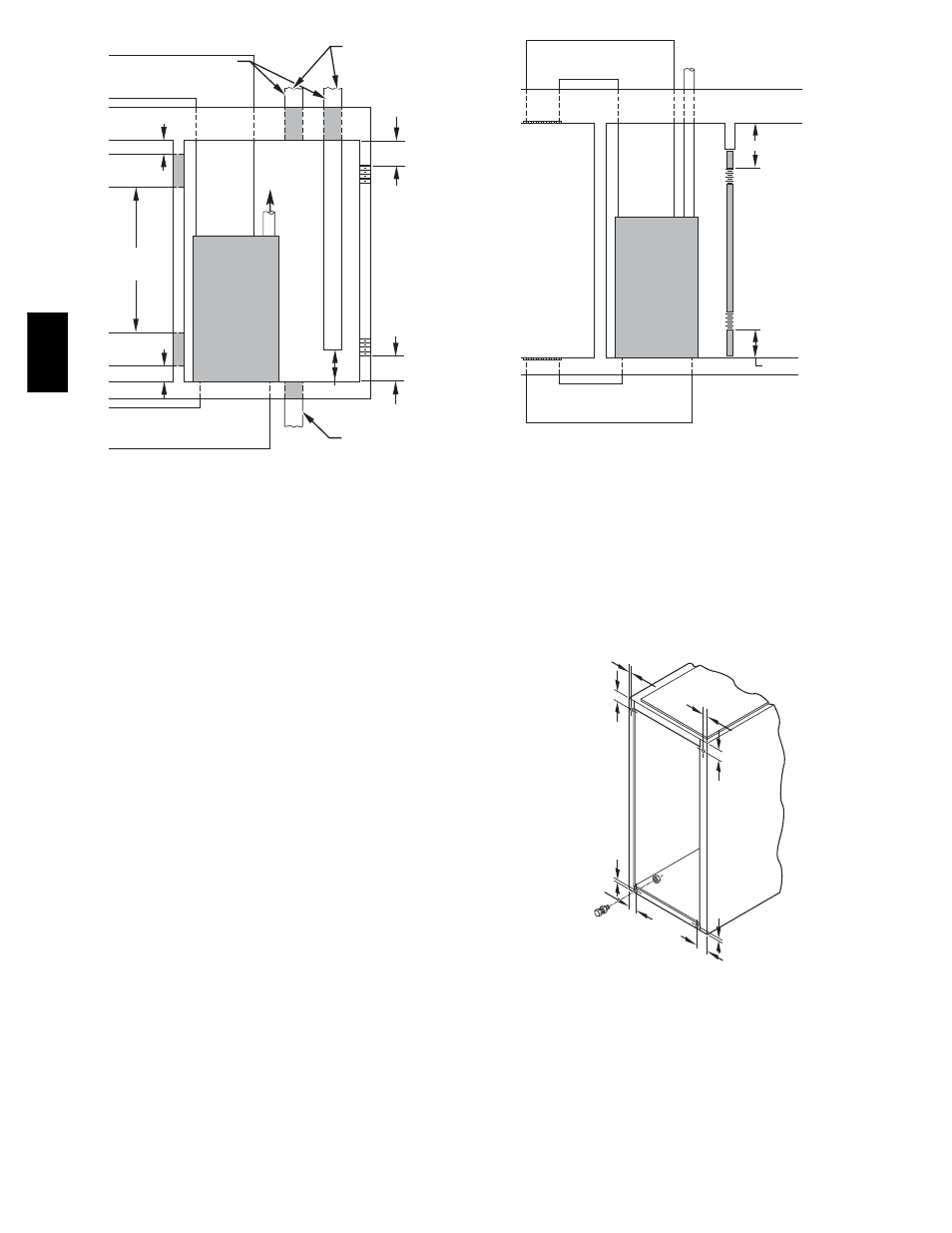

Step 1 — Leveling Legs (If Desired)

When furnace is used in upflow position with side inlet(s), leveling

legs may be desired. (See Fig. 21.) Install field--supplied,

corrosion--resistant 5/16--in. (8 mm) machine bolts and nuts.

NOTE: The maximum length of bolt should not exceed 1--1/2 in.

(38 mm).

1. Position furnace on its back. Locate and drill a 5/16--in. (8

mm) diameter hole in each bottom corner of furnace. (See

Fig. 21.) Holes in bottom closure panel may be used as

guide locations.

CIRCULATING AIR

DUCTS

6" MIN

(FRONT)

Ü

CIRCULATING AIR DUCTS

VENT THROUGH ROOF

1 SQ IN.

PER 1000

BTUH* IN DOOR

OR

WALL

12" MAX

1 SQ IN.

PER 1000

BTUH* IN DOOR

OR

WALL

12" MA X

UNCONFINED

SPACE

INTERIOR

HEATED

SPACE

CLEARANCE IN FRONT OF COMBUSTION AIR

OPENINGS SHALL

BE A

T LEAST 3 IN.

(305mm)

(152mm)

(305mm)

* Minimum opening size is 100 sq in. with minimum dimensions of 3 in. (76 mm)

† Minimum of 3 in. (76 mm) when type-B1 vent is used.

A03175

Fig. 20 -- Air for Combustion, Ventilation, and Dilution from

Indoors

2. For each hole, install nut on bolt and then install bolt and

nut in hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install flat

washer if desired.)

1

3

/

4

″

1

3

/

4

″

1

3/

4

″

1

3/

4

″

5/

16

″

5

/

16

″

5/

16

″

5/

16

″

(44mm)

(8mm)

(44mm)

(8mm)

(8mm)

(8mm)

(44mm)

(44mm)

A89014

Fig. 21 -- Leveling Legs

4. Adjust outside nut to provide desired height, and tighten inside

nut to secure arrangement.

NOTE: Bottom closure must be used when leveling legs are used.

See Bottom Closure Panel section.

Step 2 — Installation in Upflow or Downflow

Applications

NOTE: This furnace is approved for use on combustible flooring.

Special base is not required when this furnace is installed on

355A