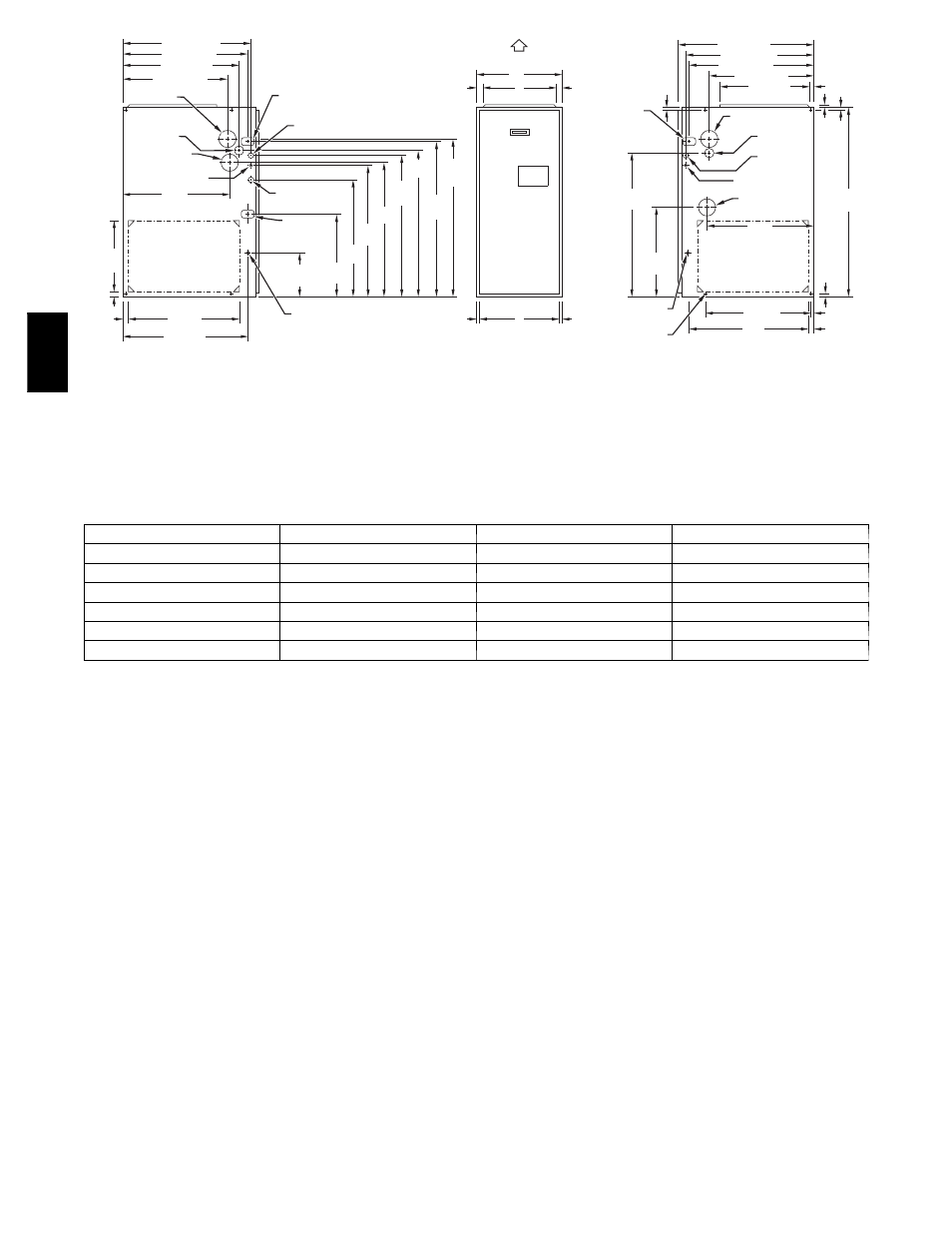

355a, Dimensions -- in. (mm) – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 4

4

NO TES: 1. Minimum retur n-air openings at fur nace , based on metal duct. If fle x duct is used,

see fle x duct manuf acturerí s recommendations f or equiv alent diameters .

2. Minimum retur n-air opening at fur nace:

a. F or 800 CFM–16-in. (406mm) round or 14

1

/

2

(368 mm)x 12-in. (305 mm) rectangle

.

b. F or 1200 CFM–20-in. (508mm) round or 14

1

/

2

(368mm)x 19

1

/

2

-in. (495mm) rectangle

.

c. F or 1600 CFM–22-in. (559mm) round or 14

1

/

2

(368mm)x 23

1

/

4

-in. (591mm) rectangle

.

d. F or airflo w requirements abo v e 1800 CFM, see Air Deliv er y tab le in Product Data

literature f or specific use of single side inlets . The use of both side inlets , a

combination of 1 side and the bottom, or the bottom only will ensure adequate

retur n air openings f or airflo w requirements abo v e 1800 CFM .

17

5

⁄

16

"

24

1

⁄

2

"

27

9

⁄

16

"

TYP

27

5

⁄

8

"

29

11

⁄

16

"

TYP

30

13

⁄

16

"

32

5

⁄

8

"

TYP

33

1

⁄

4

"

TYP

CONDENSA TE

DRAIN TRAP

LOCA TION

(AL TERNA TE

UPFL OW )

7

⁄

8

-IN . DI A (22mm)

A CCESSOR Y

PO WER ENT RY

7

⁄

8

-IN . DI A (22mm)

PO WER CONN

CONDENSA TE DRAI N

TRAP LOCA TION

(DO WNFLO W &

HORIZONT AL LEFT )

26

15

⁄

16

"

24

1

⁄

2

"

22

5

⁄

16

"

2-IN . (51 mm) COMBUSTION-

AIR CONN

1

⁄

2

-IN . (13mm) DI A

GAS CONN

2-IN (51mm)

.

VENT CONN

1

⁄

2

-IN . DIA (13mm)

THERMOST AT ENT RY

22

11

⁄

16

"

SIDE INLE T

23

1

⁄

4

" TYP

SIDE INLE T

1

1

⁄

4

"

1 "

OUTLET

26

15

⁄

16

"

28

1

⁄

2

"

22

5

⁄

16

"

19 "

13

⁄

16

"

5

⁄

8

"

5

⁄

16

"

1 "

39

7

⁄

8

"

22

1

⁄

4

" TYP

11

⁄

16

"

7

⁄

16

"

24

3

⁄

16

"

BO TT OM INLE T

18

1

⁄

4

"

22

11

⁄

16

"

2-IN . (51mm)

COMBUSTION-AIR CONN

1

⁄

2

-IN . DI A (13mm)

GAS CONN

7

⁄

8

-IN . DI A (22mm)

PO WER CONN

1

⁄

2

-IN . DI A (13 mm)

THERMOS TA T ENTR Y

2-IN . (51 mm)

VENT CONN

DIMPLE LOCA T ORS

FOR HORIZONT AL

HANGING

14

1

⁄

2

"

TYP

SIDE INLE T

9

7

⁄

16

"

TYP

26

15

⁄

16

" TYP

CONDENSA TE

DRAIN LOCA TIO N

(UPFLO W)

30

1

⁄

2

"

9

⁄

16

"

TYP

CONDENSA TE

DRAIN LOCA TION

(UPFL OW )

E

INLE T

11

/

16

"

11

/

16

"

D

13

/

16

"

13

/

16

"

OUTLET

A

AIRFL OW

26

1

⁄

4

"

26

1

⁄

4

"

CONDENSA TE DRAI N

TRAP LOCA TION

(DO WNFL OW &

HORIZONT AL RIGHT)

OR AL TERNA TE

1

⁄

2

-IN . DIA GAS CONN

(684 mm)

(667 mm)

(622 mm)

(567 mm)

(368 mm)

(32 mm)

(25mm)

(591 mm)

(684 mm)

(240 mm)

(439 mm)

(622 mm)

(700 mm)

(702 mm)

(754 mm)

(783 mm)

(829 mm)

(845 mm)

(21 mm)

(17 mm)

(17 mm)

(21 mm)

(775 mm)

(464 mm)

(14 mm)

(614 mm)

(565 mm)

(576 mm)

(483 mm)

(567 mm)

(667 mm)

(684 mm)

(724 mm)

(21 mm)

(16 mm)

(16 mm)

(1013 mm)

(25 mm)

(11 mm)

(25 mm)

(576 mm)

A05124

Dimensions -- In. (mm)

UNIT SIZE

A

D

E

040---14 / 042040

24---1/2 (622)*

22---7/8 (581)*

23 (584)*

060---14 / 042060

17---1/2 (445)

15---7/8 (403)

16 (406)

080---14 / 042080

21 (533)

19---3/8 (492)

19---1/2 (495)

080---20 / 060080

21 (533)

19---3/8 (492)

19---1/2 (495)

100---20 / 060100

21 (533)

19---3/8 (492)

19---1/2 (495)

120---20 / 060120

24---1/2 (622)

22---7/8 (581)

23 (584)

*These dimensions reflect the wider casing for the Trophy (96.6% AFUE) furnace.

Fig. 2 -- Dimensional Drawing

The 355AAV Multipoise Condensing Gas--Fired Furnaces are CSA

(formerly AGA and CGA) design--certified for natural and propane

gases (see furnace rating plate) and for installation in alcoves,

attics, basements, closets, utility rooms, crawlspaces, and garages.

The furnace is factory--shipped for use with natural gas. A CSA

listed gas conversion kit is required to convert furnace for use with

propane gas.

See Fig. 3 for required clearances to combustibles.

Maintain a 1--in. (25 mm) clearance from combustible materials to

supply air ductwork for a distance of 36 inches (914.4 mm)

horizontally from the furnace. See NFPA 90B or local code for

further requirements.

These furnaces SHALL NOT be installed directly on carpeting,

tile, or any other combustible material other than wood flooring. In

downflow installations, factory accessory floor base MUST be

used when installed on combustible materials and wood flooring.

Special base is not required when this furnace is installed on

Manufacturer’s Coil Assembly or when Manufacturer’s Coil Box

is used. These furnaces are suitable for installation in a structure

built on site or a manufactured building completed at final site. The

design of this furnace line is NOT CSA design--certified for

installation in recreation vehicles, manufactured (mobile) homes or

outdoors.

This furnace is designed for continuous return--air minimum

temperature of 60_F (16_C) db or intermittent operation down to

55_F (13_C) db such as when used with a night setback

thermostat. Return--air temperature must not exceed 80_F (27_C)

db. Failure to follow these return air limits may affect reliability of

heat exchangers, motors and controls. (See Fig. 4.)

These furnaces are shipped with the drain and pressure tubes

connected for UPFLOW applications. Minor modifications are

required when used in DOWNFLOW, HORIZONTAL RIGHT, or

HORIZONTAL

LEFT

(supply--air

discharge

direction)

applications as shown in Fig. 1. See details in Applications section.

Install this furnace only in a location and position as specified in

LOCATION and INSTALLATION sections of these instructions.

Combustion products must be discharged outdoors. Connect this

furnace to an approved vent system only, as specified in the

Combustion Air and Vent piping sections of these instructions.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for detection of leaks to

check all connections as specified in the GAS PIPING section of

these instructions.

Always install the furnace to operate within the furnace’s intended

rise range with a duct system which has an external static pressure

within the allowable range as specified in the SET

TEMPERATURE RISE section of these instructions.

355A