Warning, Vent pipe – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 36

36

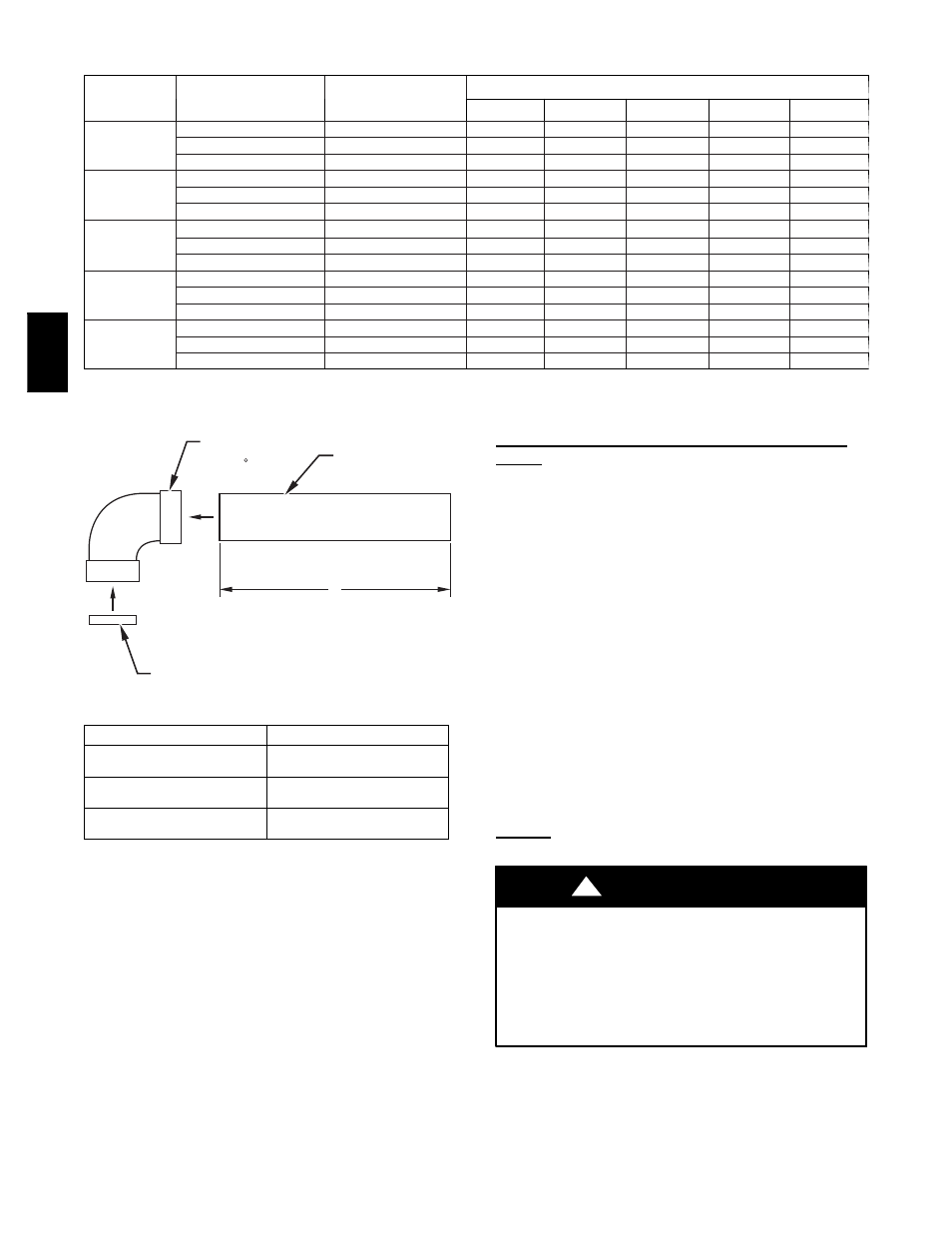

Table 10 – Maximum Allowable Exposed Vent Pipe Length (Ft / M) with Insulation in

Winter Design Temperature Ambient*

UNIT SIZE

WINTER DESIGN

TEMPERATURE

MAXIMUM PIPE

DIAMETER

INSULATION THICKNESS --- IN. (mm)†

TEMPERATURE

F (C)

DIAMETER

IN. (mm)

0 (0)

3/8” (10)

1/2” (13)

3/4” (19)

1” (25)

040

20_F (---6.7_)

2 (51)

21 (6)

37 (11)

42 (13)

50 (15)

57 (17)

0_F (---17.8_)

2 (51)

10 (3)

22 (7)

25 (8)

30 (9)

35 (11)

---20_F (---28.9_)

2 (51)

5 (2)

14 (4)

17 (5)

21 (6)

25 (8)

060

20_F (---6.7_)

2 (51)

30 (9)

55 (17)

61 (19)

70 (21)

70 (21)

0_F (---17.8_)

2 (51)

16 (5)

33 (10)

38 (12)

46 (14)

53 (16)

---20_F (---28.9_)

2 (51)

9 (3)

23 (7)

26 (8)

33 (10)

38 (12)

080

20_F (---6.7_)

2 (51)

37 (11)

65 (20)

70 (21)

70 (21)

70 (21)

0_F (---17.8_)

2 (51)

20 (6)

39 (12)

45 (14)

55 (17)

63 (19)

---20_F (---28.9_)

2 (51)

11 (3)

27 (8)

31 (9)

39 (12)

45 (14)

100

20_F (---6.7_)

2---1/2 (64)

41 (13)

70 (21)

70 (21)

70 (21)

70 (21)

0_F (---17.8_)

2---1/2 (64)

21 (6)

42 (13)

48 (15)

59 (18)

68 (21)

---20_F (---28.9_)

2---1/2 (64)

11 (3)

28 (8)

33 (10)

41 (13)

49 (15)

120

20_F (---6.7_)

3 (76)

49 (15)

70 (21)

70 (21)

70 (21)

70 (21)

0_F (---17.8_)

3 (76)

26 (8)

51 (16)

58 (18)

70 (21)

70 (21)

---20_F (---28.9_)

3 (76)

15 (5)

35 (11)

40 (12)

50 (15)

59 (18)

* Pipe length (ft./m) specified for maximum pipe lengths located in unconditioned spaces. Pipes located in unconditioned space cannot exceed total allowable

pipe length as specified in Table 11.

†

Insulation thickness based on R value of 3.5 per in. (25 mm)

FIELD-SUPPLIED

2-IN. (51 mm) DIA.

PVC PIPE

FIELD-SUPPLIED

2-IN. (51 mm) DIA.

PVC 90 ELBOW

COMBUSTION-AIR DISC LOCATION-NON DIRECT

VENT/1-PIPE SYSTEM (FACTORY-SUPPLIED IN

LOOSE PARTS BAG)

A

A05122

CASING WIDTH

A

17---1/2 (445)

8---1/2 +/--- ½

(216 +/--- 13)

21 (533)

10---1/2 +/--- ½

(267 +/--- 13)

24---1/2 (622)

12 +/--- ½

(305 +/--- 13)

Fig. 39 -- Combustion--Air Inlet Pipe Assembly --

In. (mm)

4. Insert assembled combustion air inlet pipe into intake

housing as shown in Fig. 38.

5. Drill a 1/8--in. hole in 2--in, combustion air pipe using the

hole in intake housing as a guide.

6. Install a field--supplied No. 6 or No. 8 sheet metal screw

into combustion air pipe.

7. Install casing hole filler cap (factory--supplied in loose parts

bag) in unused combustion air pipe casing hole.

NOTE: Do not attach combustion air intake pipe permanently to

combustion air intake housing since it may be necessary to remove

pipe for service of igniter or flame sensor.

Attachment of Combustion Air Intake Housing Plug

Fitting

The combustion--air intake plug fitting must be installed in unused

combustion air intake housing. This fitting must be attached by

using RTV sealant, or by drilling a 1/8--in. (3 mm) hole in fitting,

using hole in intake housing as a guide. Install a field--supplied No.

6 or No. 8 sheet metal screw.

NOTE: DO NOT OVERTIGHTEN SCREW. Breakage of intake

housing or fitting may cause air leakage to occur.

A plugged drain connection has been provided on this fitting for

use when moisture is found in combustion air intake pipe and

combustion box. If use of this drain connection is desired, drill out

fitting’s tap plug with 3/16--in. drill and connect a field--supplied

3/8--in. tube. This tube should be routed to open condensate drain

for furnace and A/C (if used), and should be trapped, as shown in

Fig. 41.

NOTE:

(Direct Vent/2--Pipe System ONLY). Moisture in

combustion air intake may be a result of improper termination.

Ensure combustion air pipe termination is similar to those as

shown in Fig. 43 so that it will not be susceptible to area where

light snow or others sources of moisture could be pulled in.

VENT PIPE

General

Furnace vent connection must be attached as shown in Fig. 38.

CARBON MONOXIDE POISONING AND PROPERTY

DAMAGE HAZARD

Failure to follow this warning could result in property damage,

personal injury, or death.

Vent pipes must be airtight. NOTE: A 2--in. (51 mm) diameter

pipe must be used within the furnace casing. Make all pipe

diameter transitions outside furnace casing per Fig. 40.

!

WARNING

NOTE: A 2--in. (51 mm) diameter pipe must be used within the

furnace casing. Make all pipe diameter transitions outside furnace

casing per Fig. 40.

355A