Step 11 — condensate drain – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 41

41

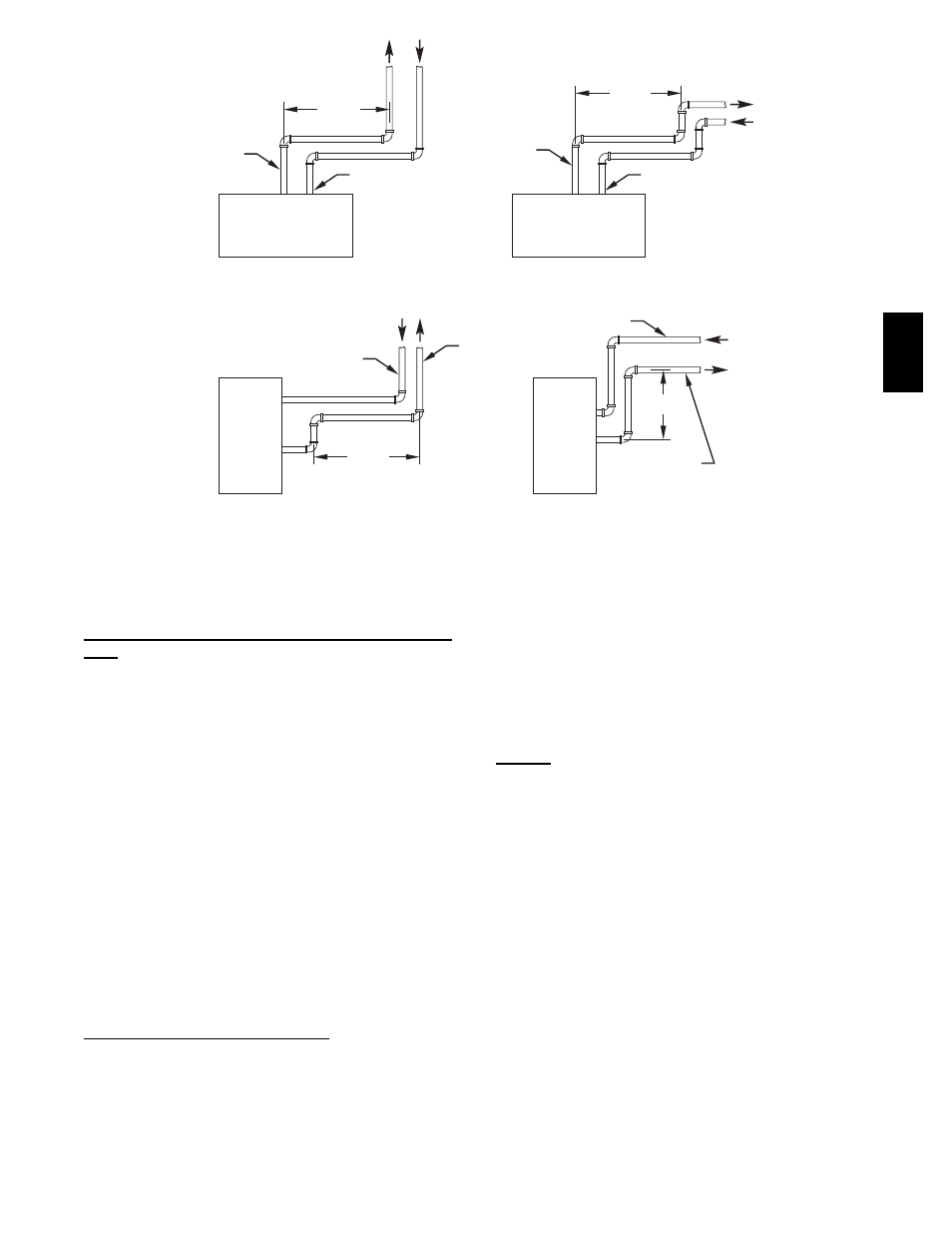

HORIZONTAL TO ROOF

HORIZONTAL TO SIDEWALL

VERTICAL TO SIDEWALL

VERTICAL TO ROOF

VENT PIPE

COMBUSTION-AIR PIPE

COMBUSTION-AIR PIPE

VENT PIPE

COMBUSTION-AIR PIPE

VENT PIPE

COMBUSTION-AIR PIPE

VENT PIPE

12

″ MIN

12

″ MIN

12

″ MIN

(304.8mm)

12

″ MIN

(304.8mm)

NOTE: A 12-in. (304.8mm) minimum offset pipe section is recommended

with short (5 to 8 ft / 1.5 to 2.5M) vent systems. This recommendation

is to reduce excessive condensate droplets.

(305mm)

(305mm)

A96230

Fig. 42 -- Short Vent (5 to 8 Ft. or 1.5M -- 2.4M) System

Two--Pipe Termination Kit (Direct Vent/2--Pipe System

Only

Determine an appropriate location for termination kit using the

guidelines provided in section “Vent Termination: General” in this

instruction.

1. Cut 2 holes, 1 for each pipe, of appropriate size for pipe size

being used.

2. Loosely install elbow in bracket and place assembly on

combustion--air pipe.

Roof terminations--Loosely install pipe coupling on prop-

erly cut vent pipe. Coupling must be positioned so bracket

will mount as shown in Fig. 43.

For applications using combustion--air pipe option, indic-

ated by dashed lines in Fig. 43, install 90_ street elbow into

90_ elbow, making a U--fitting. A 180_ U--fitting may be

used.

Sidewall terminations--Install bracket as shown in Fig. 43.

For applications using vent pipe option indicated by dashed

lines in Fig. 43, rotate vent elbow 90_ from position shown

in Fig. 43.

3. Disassemble loose pipe fittings. Clean and cement using

same procedures as used for system piping.

4. Check required dimensions as shown in Fig. 43.

Multiventing and Vent Terminations

When 2 or more 355AAV Furnaces are vented near each other,

each furnace must be individually vented. NEVER common vent

or breach vent 355AAV furnaces.

(Direct Vent/2--Pipe System ONLY)--When 2 or more 355AAV

furnaces are vented near each other, 2 vent terminations may be

installed as shown in Fig. 43, but next vent termination must be at

least 36 in. (914 mm) away from first 2 terminations. It is

important that vent terminations be made as shown in Fig. 43 to

avoid recirculation of flue gases.

Step 11 — Condensate Drain

General

Condensate trap is shipped installed in the blower shelf and factory

connected for UPFLOW applications. Condensate trap must be

RELOCATED for use in DOWNFLOW and HORIZONTAL

applications.

Condensate trap MUST be used for all applications.

An external trap is not required when connecting the field drain to

this condensate trap.

The field drain connection (condensate trap or drain tube coupling)

is sized for 1/2--in. (13 mm) CPVC, 1/2--in. PVC (13 mm), or

5/8--in. (16 mm) ID tube connection.

Drain pipe and fittings must conform to ANSI standards and

ASTM D1785, D2466, or D2846. CPVC or PVC cement must

conform to ASTM D2564 or F493. Primer must conform to

ASTM F656. In Canada, use CSA or ULC certified schedule 40

CPVC or PVC drain pipe, fittings, and cement.

When a condensate pump is required, select a pump which is

approved for condensing furnace applications. To avoid

condensate spillage, select a pump with an overflow switch.

355A