Caution, Location, Step 1 — general – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 15

15

1. Collector Box Drain Tube

a. Remove factory--installed plug from LOWER collector

box drain tube (blue and white striped label).

b. Install removed clamp and plug into UPPER collector

box drain tube (blue label) which was previously

connected to condensate trap.

c. Connect LOWER collector box drain tube (blue and

white striped label) to condensate trap. Tube does not

need to be cut.

d. Clamp tube to prevent any condensate leakage.

2. Inducer Housing Drain Tube

a. Remove factory--installed cap and clamp from LOWER

inducer housing drain connection.

b. Remove and discard UPPER (molded) inducer housing

drain tube which was previously connected to

condensate trap.

c. Install cap and clamp on UPPER inducer housing drain

connection where molded drain tube was removed.

d. Use inducer housing drain extension tube (violet label

and factory--supplied in loose parts bag) to connect

LOWER inducer housing drain connection to

condensate trap.

e. Determine appropriate length, cut, and connect tube to

condensate trap.

f. Clamp tube to prevent any condensate leakage.

3. Relief Port Tube

Refer to Pressure Switch Tubing section for connection procedure.

Condensate Trap Field Drain Attachment

Refer to Condensate Drain section for recommendations and

procedures.

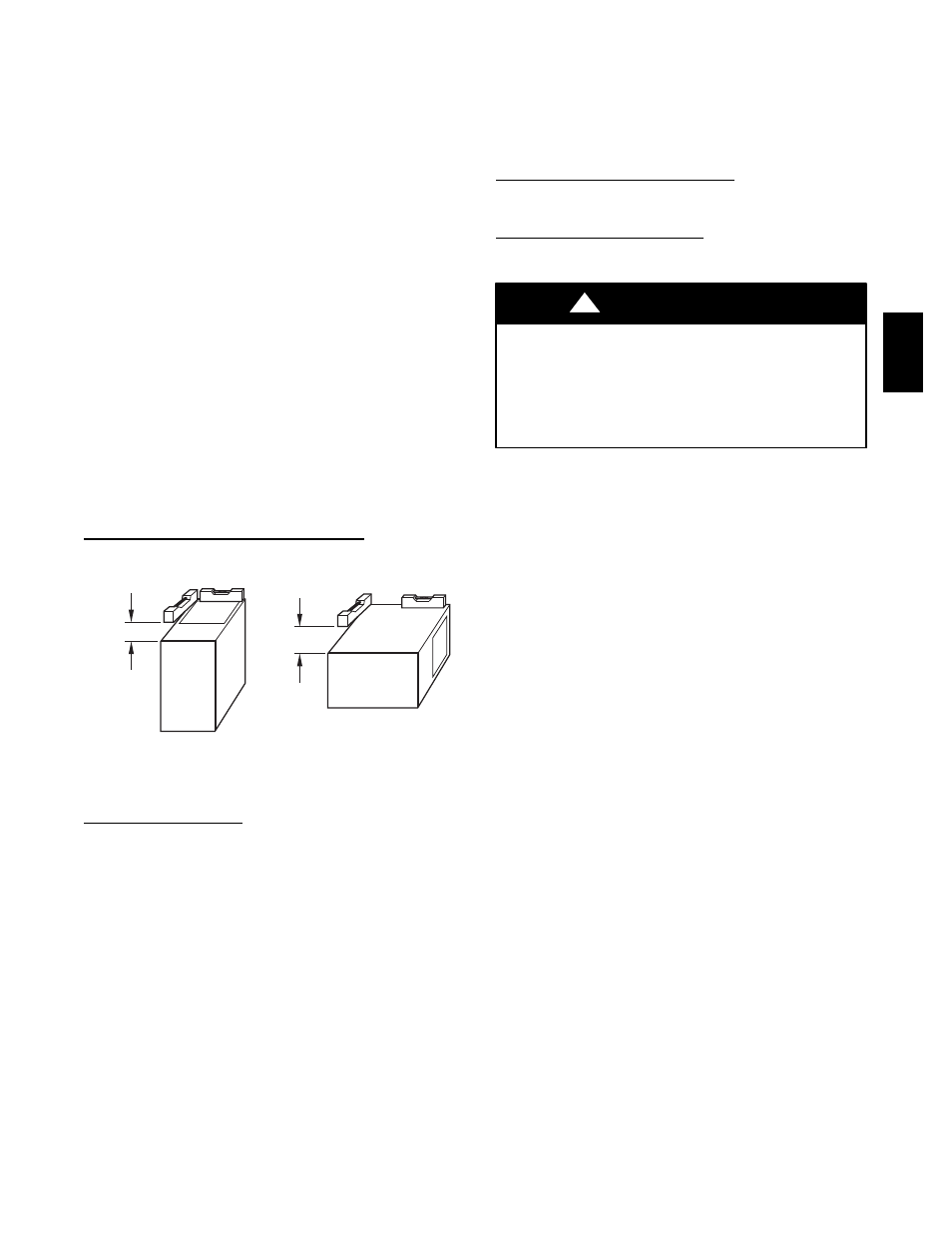

UPFLOW OR DOWNFLOW

HORIZONTAL

FRONT

LEVEL 0

″

TO

1

⁄

2

″ MAX

MIN

1

⁄

4

″

TO

1

⁄

2

″ MAX

FRONT

(0 to 13 mm)

(6 to 13 mm)

A02146

Fig. 15 -- Proper Condensate Drainage

Pressure Switch Tubing

One collector box pressure tube (pink label) is factory connected to

the pressure switch for use when furnace is installed in UPFLOW

or HORIZONTAL LEFT applications. This tube MUST be

disconnected and used for the condensate trap relief port tube. The

other collector box pressure tube (green label) which was factory

connected to the condensate trap relief port connection MUST be

connected to the pressure switch in DOWNFLOW or

HORIZONTAL RIGHT applications.

NOTE: See Fig. 14 or tube routing label on main furnace door to

check for proper connections.

Relocate tubes as described below.

1. Disconnect collector box pressure tube (pink label) attached

to pressure switch.

2. Extend collector box pressure tube (green label) which was

previously connected to condensate trap relief port

connection

by

splicing

to

small

diameter

tube

(factory--supplied in loose parts bag).

3. Connect collector box pressure tube (green label) to

pressure switch connection labeled COLLECTOR BOX.

4. Use remaining small diameter tube (factory--supplied in

loose parts bag) to extend collector box pressure tube (pink

label) which was previously connected to pressure switch.

5. Route this extended tube (pink label) to condensate trap

relief port connection.

6. Determine appropriate length, cut, and connect tube.

7. Clamp tube to relief port connection.

Condensate Trap Freeze Protection

Refer to Condensate Drain Protection section for recommendations

and procedures.

Construct a Working Platform

Construct working platform where all required furnace clearances

are met. (See Fig. 3 and 12 or 13.)

UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent unit

operation.

The condensate trap MUST be installed below furnace. See

Fig. 6 for dimensions. The drain connection to condensate trap

must also be properly sloped to an open drain.

CAUTION

!

NOTE: A 12--in. (305 mm) minimum offset pipe section is

recommended with short (5 to 8 ft./ 1.5 -- 2.4 M) vent systems.

This recommendation is to reduce excessive condensate droplets

from exiting the vent pipe. (See Fig. 12, 13 or 42.)

LOCATION

Step 1 — General

This furnace must

S

be installed so the electrical components are protected from

water.

S

not be installed directly on any combustible material other than

wood flooring (refer to SAFETY CONSIDERATIONS).

S

be located so combustion--air and vent pipe maximum lengths

are not exceeded. Refer to Table 11.

S

be located where available electric power and gas supplies meet

specifications on the furnace rating plate.

S

be attached to an air distribution system and be located as close

to the center of the distribution system as possible. Refer to Air

Ducts section.

S

be provided with ample space for servicing and cleaning.

Always comply with minimum fire protection clearances shown

on the furnace clearance--to--combustibles label. (See Fig. 3.)

This furnace may be located in a confined space without special

provisions for dilution or ventilation air.

NOTE: For upflow/downflow applications install furnace so that

it is level or pitched forward within 1/2--in. (13 mm) for proper

furnace operation. For horizontal applications pitch 1/4--in. (6

mm) minimum to 1/2--in. (13 mm) maximum forward to ensure

proper condensate drainage from secondary heat exchangers. (See

Fig. 15.)

When a furnace is installed so that supply ducts carry air circulated

by the furnace to areas outside the space containing the furnace, the

return air shall also be handled by ducts sealed to furnace casing.

The ducts terminate outside the space containing the furnace to

ensure there will not be a negative pressure condition within

equipment room or space.

355A