Caution, Combustion air pipe – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 31

31

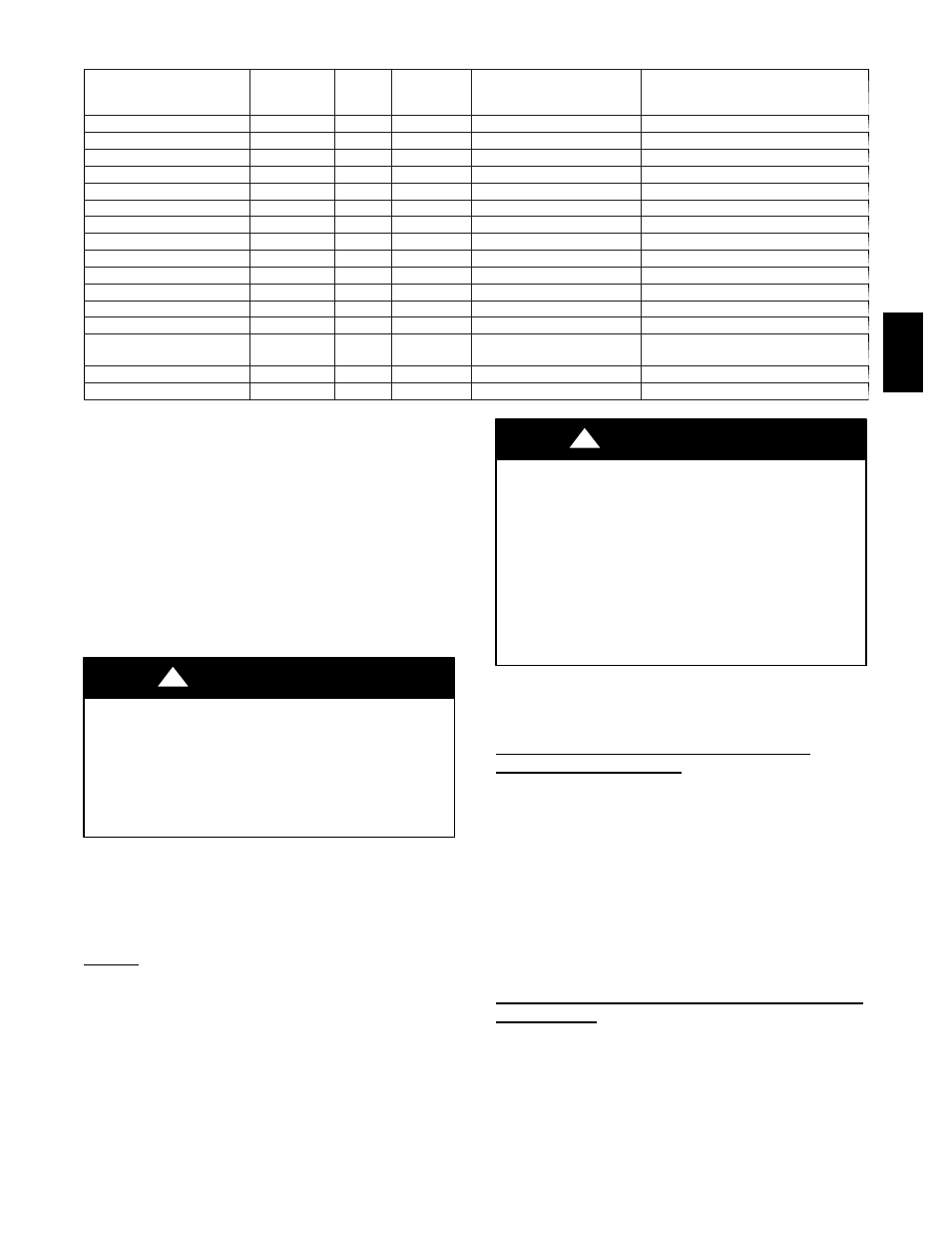

Table 7 – Approved Combustion--Air and Vent Pipe, Fitting and Cement Materials

ASTM SPECIFICATION

(MARKED ON

MATERIAL)

MATERIAL

PIPE

FITTINGS

SOLVENT CEMENT AND

PRIMERS

DESCRIPTION

D1527

ABS

Pipe

—

—

Schedule—40

D1785

PVC

Pipe

—

—

Schedule—40

D2235

For ABS

—

—

Solvent Cement

For ABS

D2241

PVC

Pipe

—

—

SDR—21 & SDR—26

D2466

PVC

—

Fittings

—

Schedule—40

D2468

ABS

—

Fittings

—

Schedule—40

D2564

For PVC

—

—

Solvent Cement

For PVC

D2661

ABS

Pipe

Fittings

—

DWV at Schedule—40 IPS sizes

D2665

PVC

Pipe

Fittings

—

DWV

F438

CPVC

—

Fittings

—

Schedule—40

F441

CPVC

Pipe

—

—

Schedule—40

F442

CPVC

Pipe

—

—

SDR

F493

For CPVC

—

—

Solvent Cement

For CPVC

F628

ABS

Pipe

—

—

Cellular Core DWV at Schedule---40

IPS sizes

F656

For PVC

—

—

Primer

For PVC

F891

PVC

Pipe

—

—

Cellular Core Schedule---40 & DWV

An abandoned masonry chimney may be used as a raceway for

properly

insulated

and

supported

combustion--air (when

applicable) and vent pipes. Each furnace must have its own set of

combustion--air and vent pipes and be terminated individually, as

shown in Fig. 43 for Direct Vent (2--Pipe) system and Fig. 44 for

Non--Direct Vent (1--Pipe) system.

A furnace shall not be connected to a chimney flue serving a

separate appliance designed to burn solid fuel.

Other gas appliances with their own venting system may also use

the abandoned chimney as a raceway providing it is permitted by

local code, the current edition of the National Fuel Gas Code and

the vent or liner manufacturer’s installation instructions. Care must

be taken to prevent the exhaust gases from one appliance from

contaminating the combustion air of other gas appliances.

UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent unit

operation.

When vent pipe is exposed to temperatures below freezing,

such as when it passes through an unheated space or when a

chimney is used as a raceway, pipe must be insulated as shown

in Table 10 with Armaflex--type insulation.

CAUTION

!

Furnace combustion air and vent pipe connections are sized for

2--in. (51 mm) pipe. Any pipe size change should be made outside

furnace casing in vertical pipe. The transition has to be made as

close to the furnace as reasonably possible. See Fig. 40.

COMBUSTION AIR PIPE

General

Furnace combustion--air connection must be attached as shown in

Fig. 38. Combustion--air intake housing plug may need to be

relocated in some applications.

For Non--Direct Vent (1--Pipe) system, combustion--air must

terminate outside of furnace casing with 1 elbow. Orient elbow so

that its opening faces down for upflow or downflow applications.

Orient elbow so that its opening faces sideways (left or right) for

horizontal left or horizontal right applications (See Fig. 38.)

Maintain a 3--in minimum clearance between the opening of the

combustion--air inlet pipe and any object.

UNIT CORROSION HAZARD

Excessive exposure to contaminated combustion air may result

in safety and performance related problems.

Combustion air must not be taken from inside structure

because inside air is frequently contaminated by halogens,

which include fluorides, chlorides, bromides, and iodides.

These elements are found in aerosols, detergents, bleaches,

cleaning solvents, salts, air fresheners, adhesives, paint, and

other household products. Locate combustion--air inlet as far

as possible from swimming pool and swimming pool pump

house. pipe.

CAUTION

!

NOTE: All pipe joints must have cemented attachment of

combustion--air inlet pipe to inlet housing connection, since it may

be necessary to remove pipe for servicing.

Assembly of Combustion Air Pipe (Non--Direct

Vent/1--Pipe System ONLY)

1. Permanently install perforated disk assembly (factory sup-

plied in loose parts bag) in combustion--air elbow using

RTV or by cementing, as shown in Fig. 39. For 120,000

Btuh size units only: separate the 2 halves of perforated disk

assembly and use only the shouldered disk half.

2. Determine the length of straight portion of combustion--air

inlet pipe from Fig. 39.

3. Cut field--supplied 2--in. (51 mm) diameter PVC pipe to

length as determined per Fig. 39.

4. Permanently attach elbow/perforated disk assembly to

straight portion of pipe using RTV or by cementing as

shown in Fig. 39.

Assembly of Combustion Air Pipe (Direct Vent--2--Pipe

System ONLY)

1. Using Table 11, individually determine the smallest

combustion air and vent pipe diameters permitted for each

pipe. Pick the larger of these two pipe diameters and use this

for both combustion--air and vent pipes.

NOTE: Do not count elbows or pipe sections in terminations or

within furnace (All elbows shown in Fig. 43 are not to be counted).

355A