Warning, Start--up, adjustments and safety check, Application – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 43: Condensate drain protection, Step 1 — general

43

Table 12 – Vent Termination Kit for Direct Vent / 2--Pipe System

DIRECT VENT (2 PIPE) TERMINATION KIT

TERMINATION SYSTEM

DIAMETER OF COMBUSTION AIR AND

VENT PIPES --- IN. (MM)

2---in. (51 mm) Concentric Vent Kit

Single Penetration of Wall or Roof

1, 1---1/2, 2, or 2---1/2

(25, 38, 51, or 64)

3---in. (76 mm) Concentric Vent Kit

Single Penetration of Wall or Roof

2---1/2, 3 or 4 (64, 76, or 102)

2---in. (51 mm)Termination Bracket Kit

2Pipe Termination System

1, 1---1/2 or 2 (25, 38, or 51)

3---in. (76 mm) Termination Bracket Kit

2Pipe Termination System

2---1/2, 3 or 4 (64, 76, or 102)

Furnace condensate is mildly acidic, typically in the pH range of

3.2 to 4.5. Due to corrosive nature of this condensate, a condensate

pH neutralizing filter may be desired. Check with local authorities

to determine if a pH neutralizer is required.

APPLICATION

The furnace, A/C, and humidifier drains may be combined and

drained together. The A/C drain must have an external,

fieldsupplied trap prior to the furnace drain connection. All drain

connections (furnace, A/C, or humidifier) must be terminated into

an open or vented drain as close to the respective equipment as

possible to prevent siphoning of the equipment’s drain.

See Fig. 45 for example of possible field drain attachment using

1/2--in. (13 mm) CPVC or PVC tee for vent and A/C or humidifier

drain connection.

Outdoor draining of the furnace is permissible if allowed by local

codes. Caution should be taken when freezing ambient may freeze

drain pipe and prohibit draining.

PERSONAL INJURY HAZARD

Failure to follow this warning could result in property damage

and personal injury or death.

Caution should be taken to prevent draining causing slippery

conditions . Excessive condensate draining may cause

saturated soil conditions which may result in damage to plants.

!

WARNING

CONDENSATE DRAIN PROTECTION

Freezing condensate left in condensate trap and drain line may

cause cracks, and possible water damage may occur. If freeze

protection is required, use condensate freeze protection accessory

or equivalent 3 to 6 watt per ft. at 120v and 40_F (4_C)

self--regulating, shielded, and waterproof heat tape. See Installation

Instructions supplied with accessory or heat tape manufacturer’s

recommendations.

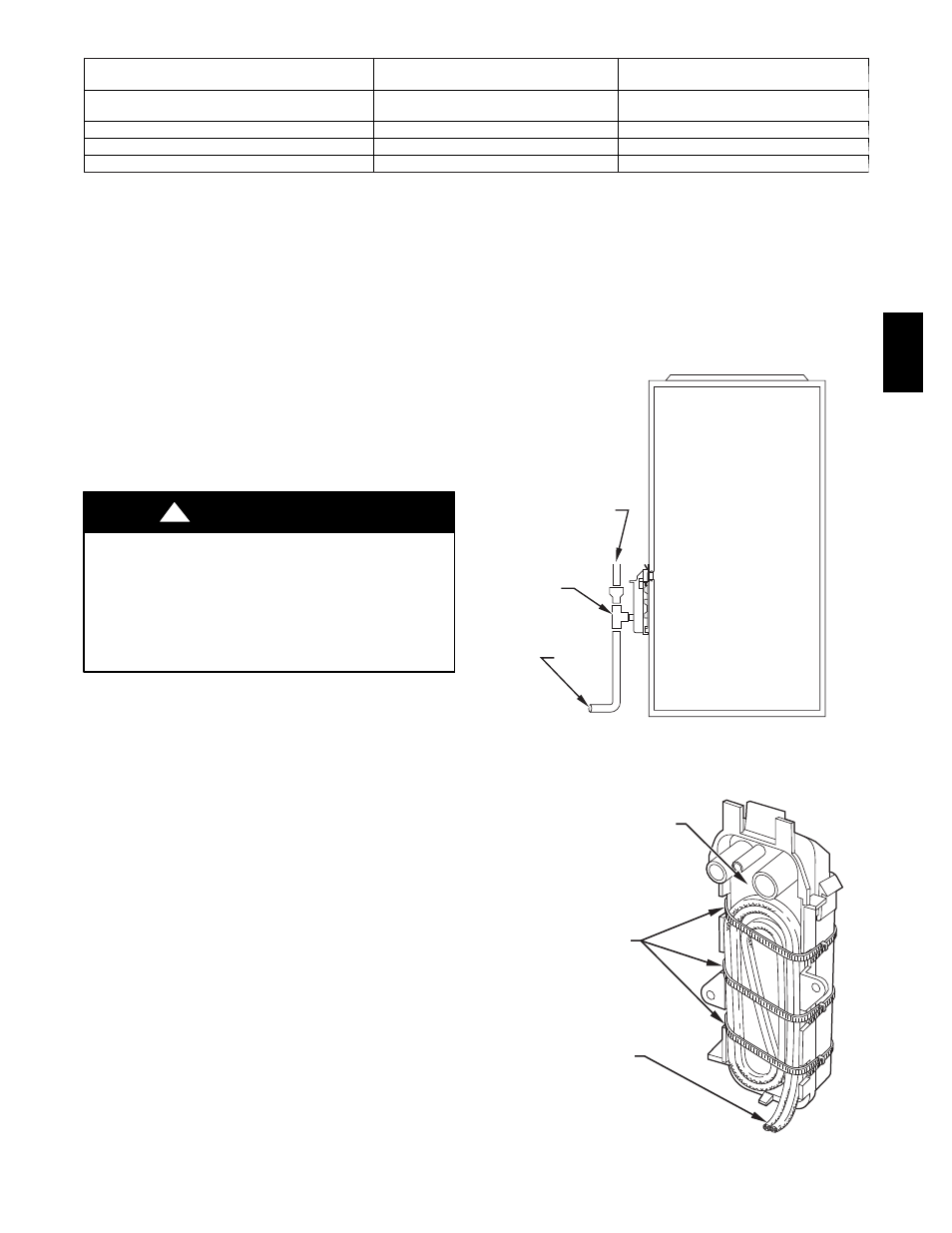

1. Fold heat tape in half and wrap on itself 3 times.

2. Locate heat tape between sides of condensate trap back.

(See Fig. 46.)

3. Use wire ties to secure heat tape in place. Wire ties can be

positioned in notches of condensate trap sides. (See Fig.

46.)

4. Wrap field drain pipe with remaining heat tape,

approximately 1 wrap per ft.

5. When using field--supplied heat tape, follow heat tape

manufacturer’s instructions for all other installation

guidelines.

START--UP, ADJUSTMENTS AND SAFETY

CHECK

Step 1 — General

1. Furnace must have a 115--v power supply properly

connected and grounded.

NOTE: Proper polarity must be maintained for 115--v wiring. If

polarity is incorrect, control status indicator light flashes rapidly

and furnace does not operate.

2. Thermostat wire connections at terminals R, W/W1, G, and

Y/Y2 must be made at 24--v terminal block on furnace

control.

3. Natural gas service pressure must not exceed 0.5 psig

(14--in. wc), but must be no less than 0.16 psig (4.5--in. wc).

4. Blower access panel must be in place to complete 115--v

electrical circuit to furnace.

OPEN STAND

PIPE FOR

A/C OR

HUMIDIFIER

DRAIN

TEE

TO OPEN

DRAIN

A94054

Fig. 45 -- Example of Field Drain Attachment

CONDENSATE TRAP

WIRE TIE(S)

HEAT TAPE

(3 WRAPS MINIMUM)

A93036

Fig. 46 -- Condensate Trap Heat Tape

355A