Caution, Warning – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 17

17

UNIT DAMAGE HAZARD

Failure to follow this caution may result in minor property or

unit damage.

The furnace can operate in the high--heat mode when certain

fault conditions occur. The following precautions should be

taken:

1. Size gas piping based on the high--heat input

2. Check the high--heat input and adjust it per the main

literature instruction.

CAUTION

!

Step 3 — Furnace Location Relative to Cooling

Equipment

The cooling coil must be installed parallel with or on downstream

side of furnace to avoid condensation in heat exchanger. When

installed parallel with a furnace, dampers or other means used to

control flow of air shall be adequate to prevent chilled air from

entering furnace. If dampers are manually operated, they must be

equipped with a means to prevent operation of either unit unless

damper is in full--heat or full--cool position.

Step 4 — Hazardous Locations

FIRE, EXPLOSION, INJURY OR DEATH HAZARD

Improper location or inadequate protection could result in fire

or explosion.

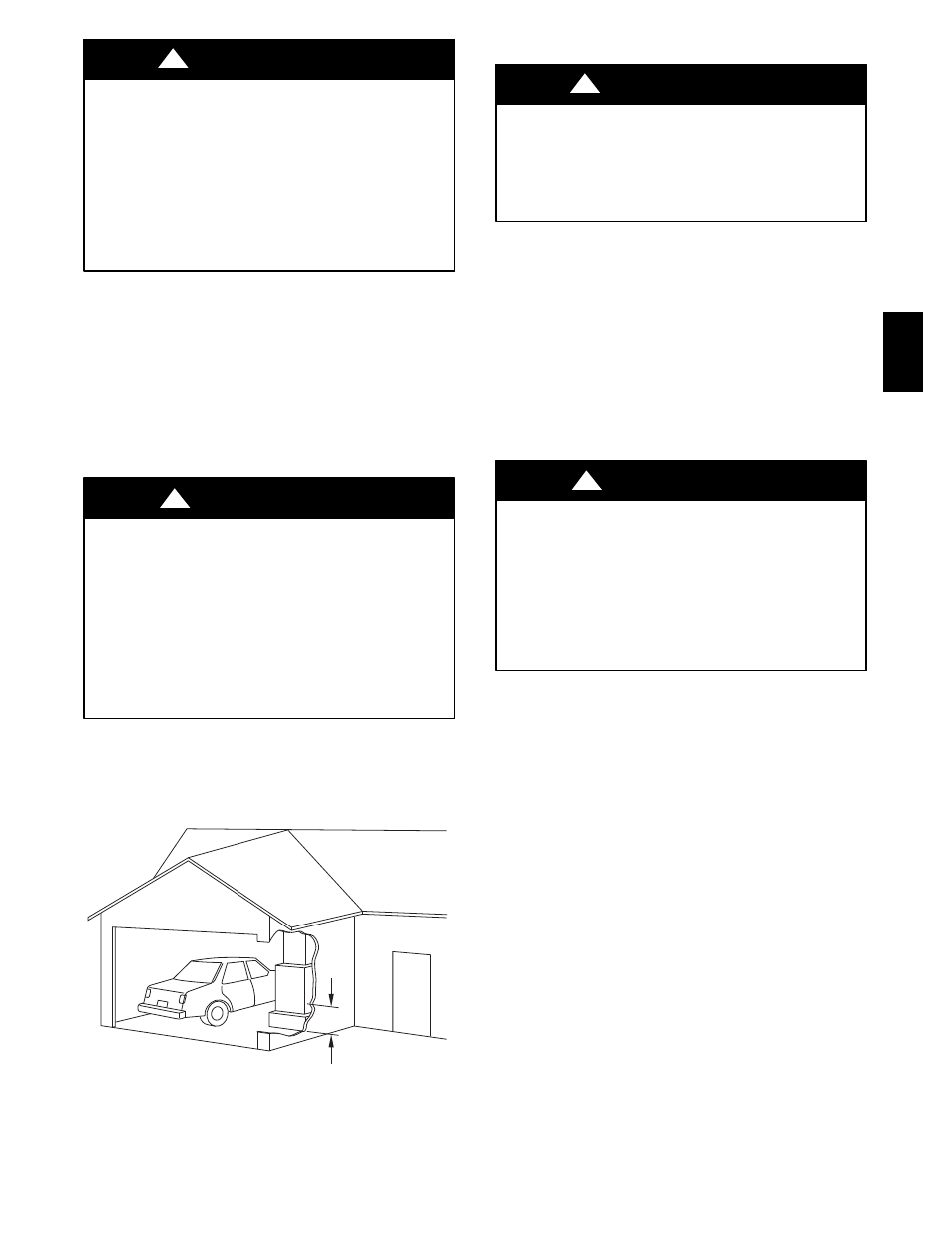

When furnace is installed in a residential garage, it must be

installed so that burners and ignition sources are located a

minimum of 18 in. (457 mm) above floor. The furnace must

be located or protected to avoid physical damage by vehicles.

When furnace is installed in a public garage, airplane hangar,

or other building having a hazardous atmosphere, unit must be

installed in accordance with requirements of National Fire

Protection Association, Inc. (See Fig. 18.)

!

WARNING

Step 5 — Furnace Location and Application

DIRECT VENT (2--PIPE) APPLICATION

Furnace may be located in a confined space without special

provisions for dilution or ventilation air.

18-IN. (457.2 mm)

MINIMUM TO BURNERS

A93044

Fig. 18 -- Installation in a Garage

NON--DIRECT VENT (1--PIPE) APPLICATION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in intermittent unit

operation.

Do not install furnace in a corrosive or contaminated

atmosphere. Make sure all combustion and circulating air

requirements are met.

CAUTION

!

Refer to the AIR FOR COMBUSTION AND VENTILATION

section for details.

AIR FOR COMBUSTION AND VENTILATION

Provisions for adequate combustion, ventilation, and dilution air

must be provided in accordance with:

S

U.S. Installations: Section 9.3 of the NFGC, Air for Combustion

and Ventilation and applicable provisions of the local building

codes.

S

Canadian Installations: Part 8 of the NFPA54/ANSI

Z223.1--2006 CAN/CSA--B149.1--05, Venting Systems and Air

Supply for Appliances and all authorities having jurisdiction.

FURNACE CORROSION HAZARD

Failure to follow this warning could result in reduced furnace

component life.

Air for combustion must not be contaminated by halogen

compounds, which include fluoride, chloride, bromide, and

iodide. These elements could corrode heat exchangers and

shorten furnace life. Air contaminants are found in aerosol

sprays, detergents, bleaches, cleaning solvents, salts, air

fresheners, and other household products.

!

WARNING

The following types of furnace installations may require

OUTDOOR AIR for combustion due to chemical exposures:

S

Commercial buildings

S

Buildings with indoor pools

S

Laundry rooms

S

Hobby or craft rooms, and

S

Chemical storage areas

If air is exposed to the following substances, it should not be used

for combustion air, and outdoor air may be required for

combustion:

S

Permanent wave solutions

S

Chlorinated waxes and cleaners

S

Chlorine based swimming pool chemicals

S

Water softening chemicals

S

De--icing salts or chemicals

S

Carbon tetrachloride

S

Halogen type refrigerants

S

Cleaning solvents (such as perchloroethylene)

S

Printing inks, paint removers, varnishes, etc.

S

Hydrochloric acid

S

Cements and glues

S

Antistatic fabric softeners for clothes dryers

S

Masonry acid washing materials

All fuel--burning equipment must be supplied with air for fuel

combustion. Sufficient air must be provided to avoid negative

355A