Warning – Bryant Bruant 4 Way Gas 355AAV User Manual

Page 30

30

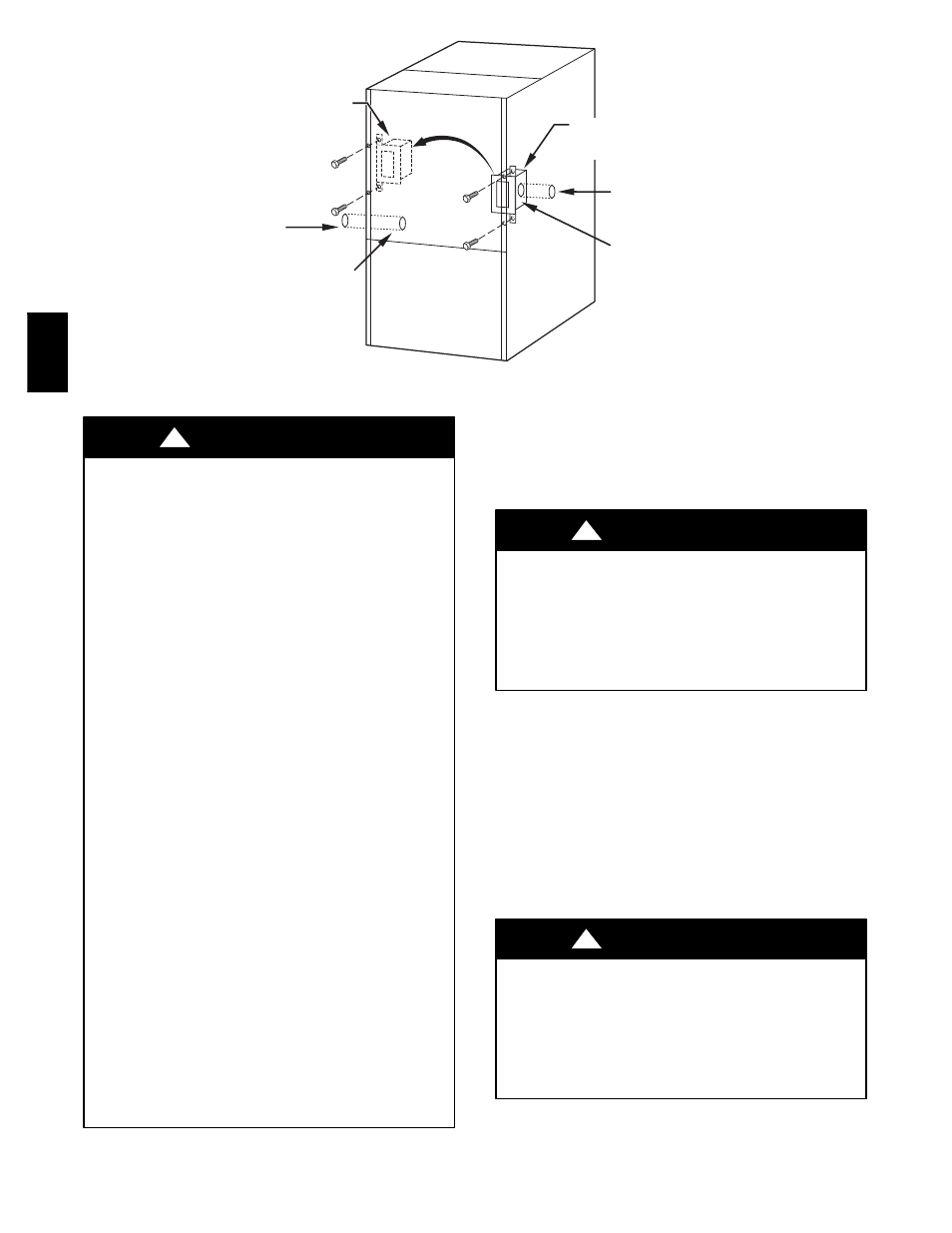

FACTORY

INSTALLED

LOCATION

ALTERNATE

FIELD

LOCATION

POWER ENTRY HOLE

FILLER PLUG (FACTORY-

SUPPLIED LOOSE PARTS BAG)

UNUSED 7/8-IN. (22 mm) DIAMETER

POWER ENTRY HOLES

UNUSED 7/8-IN. (22 mm) DIAMETER

POWER ENTRY HOLES

POWER ENTRY HOLE

FILLER PLUG (FACTORY-

SUPPLIED LOOSE PARTS BAG)

A05058

Fig. 35 -- Relocating J-Box

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance

connected to the venting system being placed into operation

could result in carbon monoxide poisoning or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into operation,

while all other appliances connected to the venting system are

not in operation:

1. Seal any unused openings in venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1--2006/NFPA 54--2006 or the CSA B149.1--05, Natural

Gas and Propane Installation Code and these instructions.

Determine that there is no blockage or restriction, leakage,

corrosion and other deficiencies, which could cause an unsafe

condition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other spaces

of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they are operating at

maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so appliance is

operating continuously.

7. Test for spillage from draft hood equipped appliances at the

draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

8. If improper venting is observed during any of the above

tests, the venting system must be corrected in accordance with

the National Fuel Gas Code, ANSI Z223.1-- 2006/NFPA

54--2006 and/or CSA B149.1--05, Natural Gas and Propane

Installation Code.

9. After it has been determined that each appliance connected

to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace dampers

and any other gas--fired burning appliance to their previous

conditions of use.

!

WARNING

MATERIALS

Combustion--air and vent pipe, fittings, primers, and solvents must

conform to American National Standards Institute (ANSI)

standards and American Society for Testing and Materials (ASTM)

standards. See Table 7 for approved materials for use in the U.S.A.

FIRE AND EXPLOSION HAZARD

Failure to follow this warning could result in fire, property

damage, personal injury or death.

Solvent cements are combustible. Keep away from heat,

sparks, and open flame. Use only in well--ventilated areas.

Avoid breathing in vapor or allowing contact with skin or

eyes.

!

WARNING

In Canada, construct all combustion--air and vent pipes for this unit

of CSA or ULC listed schedule--40 PVC, PVC--DWV or

ABSDWV pipe and pipe cement. SDR pipe is NOT approved in

Canada.

In direct vent (2--pipe) systems, combustion air and vent pipes

must terminate together in same atmospheric pressure zone, either

through roof or sidewall (roof termination preferred), using

accessory termination kit. See Table 8 for required clearances.

In non--direct vent (1--pipe) system, vent pipe termination must be

installed with adequate clearances to building openings and

equipment to comply with national and local codes. See Table 9 for

required clearances.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in property damage,

personal injury, or death.

All combustion--air and vent pipes must be airtight and

watertight. Pipes must also terminate exactly as shown in Fig.

43 for direct vent (2--pipe) system and Fig. 44 for non--direct

vent (1--pipe) system.

!

WARNING

355A