Bryant Bruant 4 Way Gas 355AAV User Manual

Page 46

46

A99118

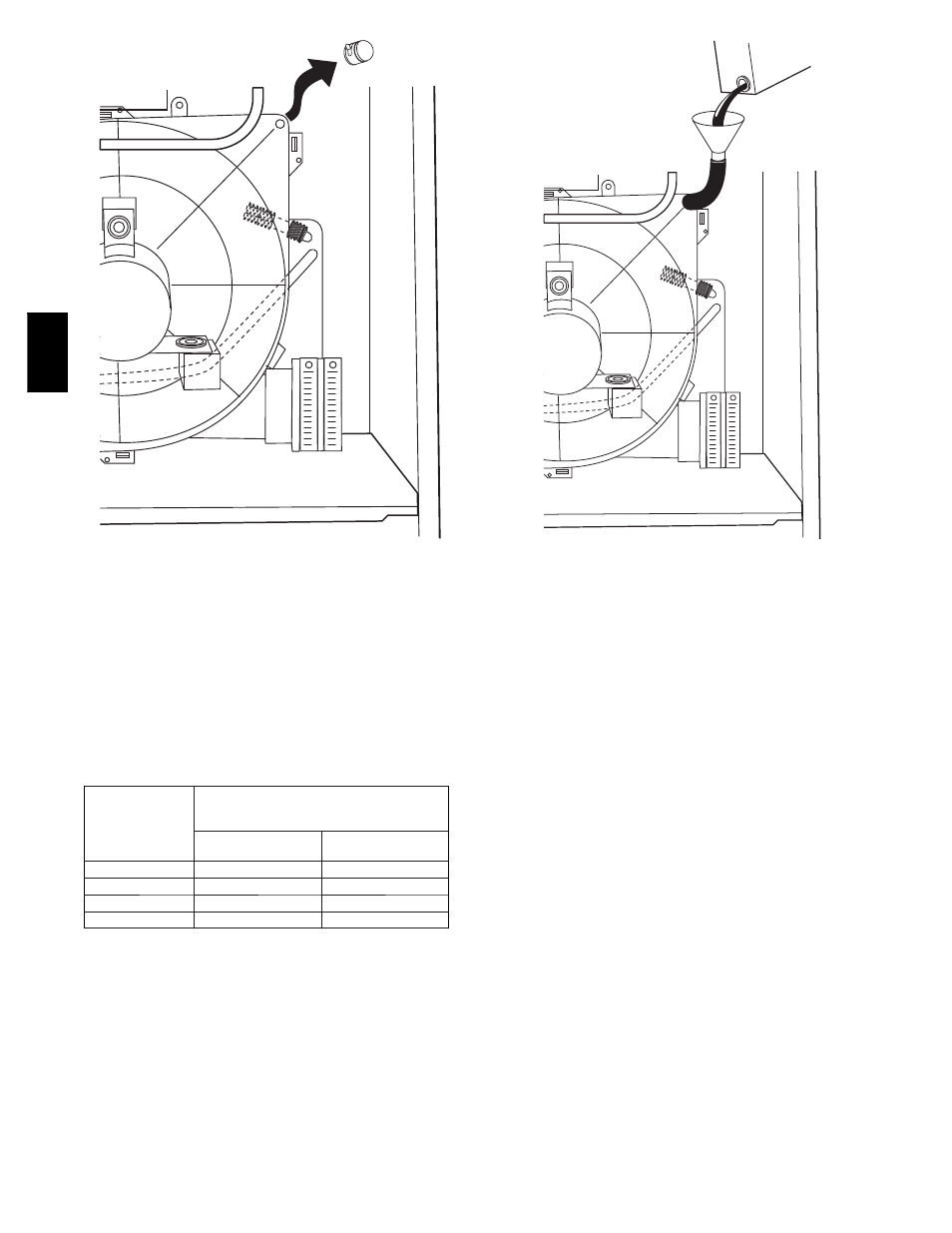

Fig. 49 -- Inducer Housing Drain Tube

SINGLE--STAGE THERMOSTAT AND TWO--

STAGE HEATING (ADAPTIVE MODE)

See Fig. 32 or 58 for thermostat connections

NOTE:

Low--heat--only switch, SW1--2, selects either the

low--heat-- only operation mode when ON, (see item 2. below) or

adaptive heating mode when OFF, in response to a call for heat.

(See Fig. 37.) When the W2 thermostat terminal is energized, it

will always cause high--heat operation when the R to W circuit is

closed, regardless of the setting of the low--heat only switch.

DESIRED

HEATING

MODE

BLOWER OFF

DELAY (SEC)

SETUP SWITCH (SW1---7 AND SW1---8)

POSITION

SW1---7

SW1---8

90

OFF

OFF

120

ON

OFF

150

OFF

ON

180

ON

ON

This furnace can operate as a two--stage furnace with a single--stage

thermostat because furnace control CPU includes a programmed

adaptive sequence of controlled operation, which selects low--heat

or high--heat operation. This selection is based upon the stored

history of the length of previous gas heating periods of the

single--stage thermostat.

The furnace will start up in either low-- or high--heat. If the furnace

starts up in low--heat, the furnace control CPU determines the

low--heat on time (from 0 to 16 minutes) which is permitted before

switching to high--heat.

A99119

Fig. 50 -- Filling Condensate Trap

If power is interrupted, the stored history is erased. When this

happens, the control CPU will initially select low--heat for up to 16

minutes and then switch to high--heat, as long as the thermostat

continues to call for heat. Subsequent selection is based on stored

history of thermostat cycle times.

The wall thermostat “calls for heat”, closing the R to W circuit. The

furnace control CPU performs a self--check, verifies the low--heat

and high--heat pressure switch contacts LPS and HPS are open.

1. Inducer Prepurge Period -- The furnace control CPU turns

on inducer motor IDM and slowly increases the inducer

motor speed. When the low--heat pressure switch LPS

closes, inducer motor RPM is noted by the furnace control

CPU, and a 25--sec. prepurge period begins. The RPM is

used to evaluate vent system resistance. This evaluation is

then used to determine the required RPM necessary to

operate the inducer motor during the low--heat prepurge

period and low--heat mode.

NOTE: The heat cycle can start in either high--or low--heat. If a

high--heat cycle is initiated, the furnace control CPU will

deenergize the high--heat pressure switch relay HPSR to close the

NC contact and continues to increase the inducer motor speed after

the low--heat pressure switch LPS closes. When the high--heat

pressure switch closes, inducer motor RPM is noted by the furnace

control CPU before the 25--sec prepurge period begins. The RPM

is used to evaluate vent system resistance. This evaluation is then

used to determine the required RPM necessary to operate the

inducer motor in high--heat mode.

2. Igniter Warm--Up -- At end of the prepurge period, the Hot

Surface Igniter HSI is energized for a 17--sec igniter

warm--up period.

3. Trial--For--Ignition Sequence -- When the igniter warm--up

period is completed, the main gas valve relay contacts GVR

close to energize the gas valve GV, the gas valve opens. The

gas valve GV permits gas flow to the burners where it is

355A