Buhler 2180 User Manual

Page 207

SECTION 3 - LUBRICATION AND MAINTENANCE

3-19

EVERY 50 HOURS

OPERATION 9

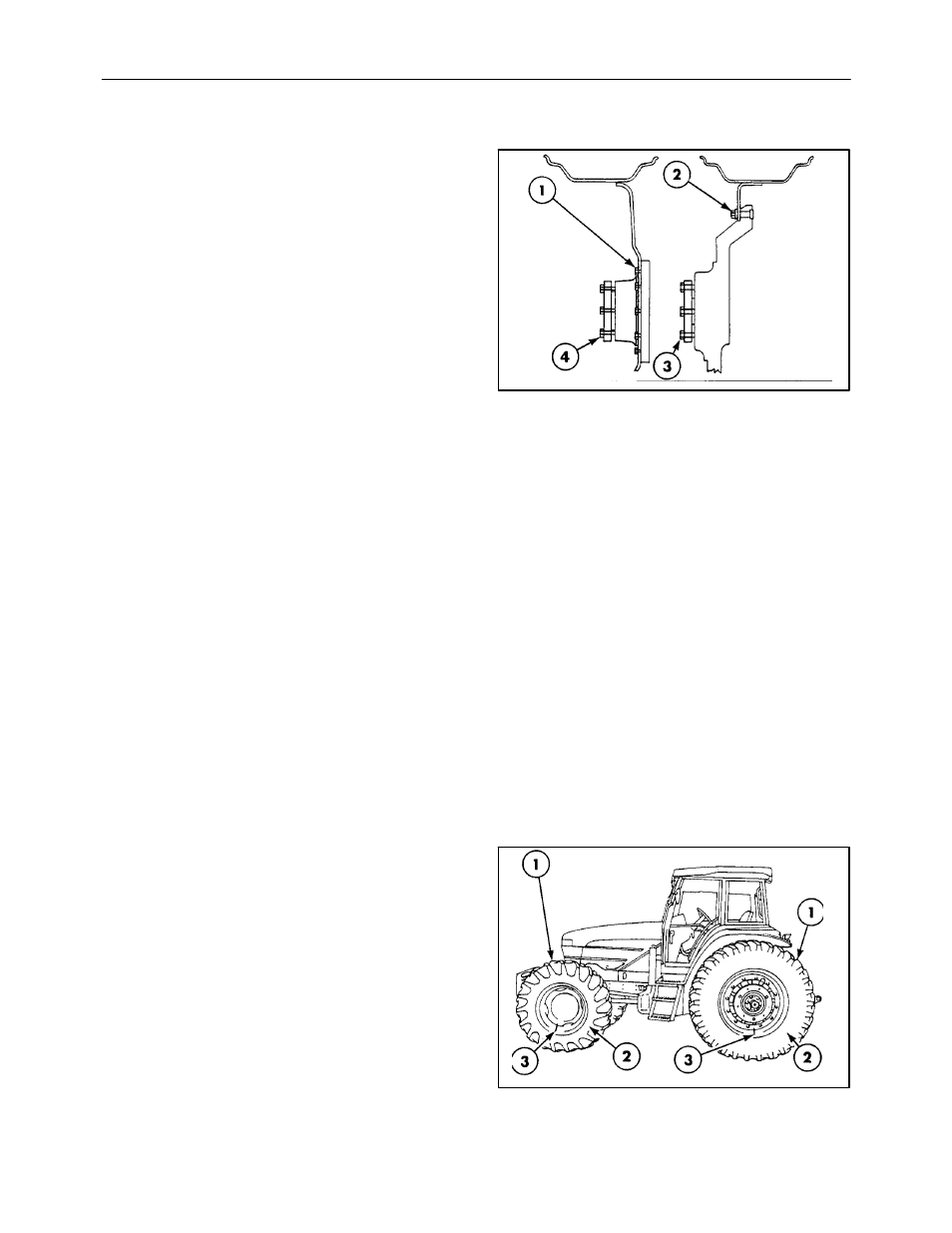

CHECK FRONT AND REAR WHEEL

HARDWARE, REAR WHEEL WEIGHT

HARDWARE

Check the front and rear wheel hardware, rear wheel

weight hardware for tightness using a torque wrench

or torque multiplier. The specified torque figures are

shown in the table below:

Front disc to hub nuts, 1

203 N·m

(two wheel drive)

(150 ft.-lbs.)

Front disc to hub nuts, 1

700 N·m

(four wheel drive)

(515 ft.-lbs.)

Front disc to rim nuts, 2

345 N·m

(four wheel drive)

(255 ft.-lbs.)

Rear wedge to disc bolts, 3

391 N·m

(cast disc wheels)

(290 ft.-lbs.)

Rear disc to rim nuts (Grade 8), 2

596 N·m

(cast disc wheels)

(440 ft.-lbs.)

Rear wedge to hub bolts, 4

391 N·m

(steel disc wheels)

(290 ft.-lbs.)

Rear disc to hub bolts, 1

800 N·m

(steel disc wheels)

(590 ft.-lbs.)

Rear wedge to hub bolts, 4

391 N·m

(dual wheel - six wedge bolts)

(290 ft.-lbs.)

Rear wedge to hub bolts, 4

391 N·m

(dual wheel - four wedge bolts)

(290 ft.-lbs.)

Rear wheel weight mounting bolts

224 N·m

(165 ft. lbs.)

26

OPERATION 10

CHECK TIRE PRESSURES AND TIRE

CONDITION

Check and adjust the front and rear tire pressures.

Inspect the tread, 1, and sidewalls, 2, for damage.

Adjust the tire pressures to suit the load being

carried.

See “Tire Pressures and Permissable Loads” in

Section 5.

NOTE: If the tires are ballasted with a calcium

chloride/water solution, use a special tire gauge as

the solution will corrode a standard-type gauge.

Check pressure with the valve stem, 3, at the bottom.

27