Buhler 2180 User Manual

Page 120

SECTION 2 - OPERATION

2-74

ATTACHING EQUIPMENT TO THE PTO

SHAFT

Mount or hitch the equipment to the tractor as

outlined in either “3-Point Hitch Linkage” or “Drawbar

- Towing Attachments” sections.

1. With the engine stopped, all equipment lowered,

and the PTO stopped, unscrew the PTO shaft

cover, 3, Figure 102.

2. Attach the equipment drive shaft to the tractor

PTO shaft. Be certain that the equipment drive

shaft coupler lock pin, 1, engages the PTO shaft

lock groove. If the coupler does not have a lock,

pin the coupler to the shaft.

3. MOUNTED EQUIPMENT ONLY: Raise and

lower the linkage and check for interference.

Make sure the PTO shaft is not binding in the fully

raised position. If necessary, set the height limit

control knob on the right-hand console to limit

raising height. Also study the instructions in

“3-Point Hitch Controls.”

4. TRAILING EQUIPMENT ONLY: Be certain that

the drawbar is fixed in the center position and that

the drawbar is set at the correct length for the

PTO speed selected. See “Drawbar - Towing

Attachments.”

5. Position the PTO master shield, 1, Figure 102, in

the proper position before operating the PTO.

108

6. Check that the PTO driveline is not overex-

tended, bottomed out, or at an excessive angle

and the driveline shield does not contact the PTO

guard or drawbar.

IMPORTANT: Before operating PTO driven equip-

ment, check to make sure the driveline will not bottom

out or become disengaged. Use the following to

determine PTO shaft engagement.

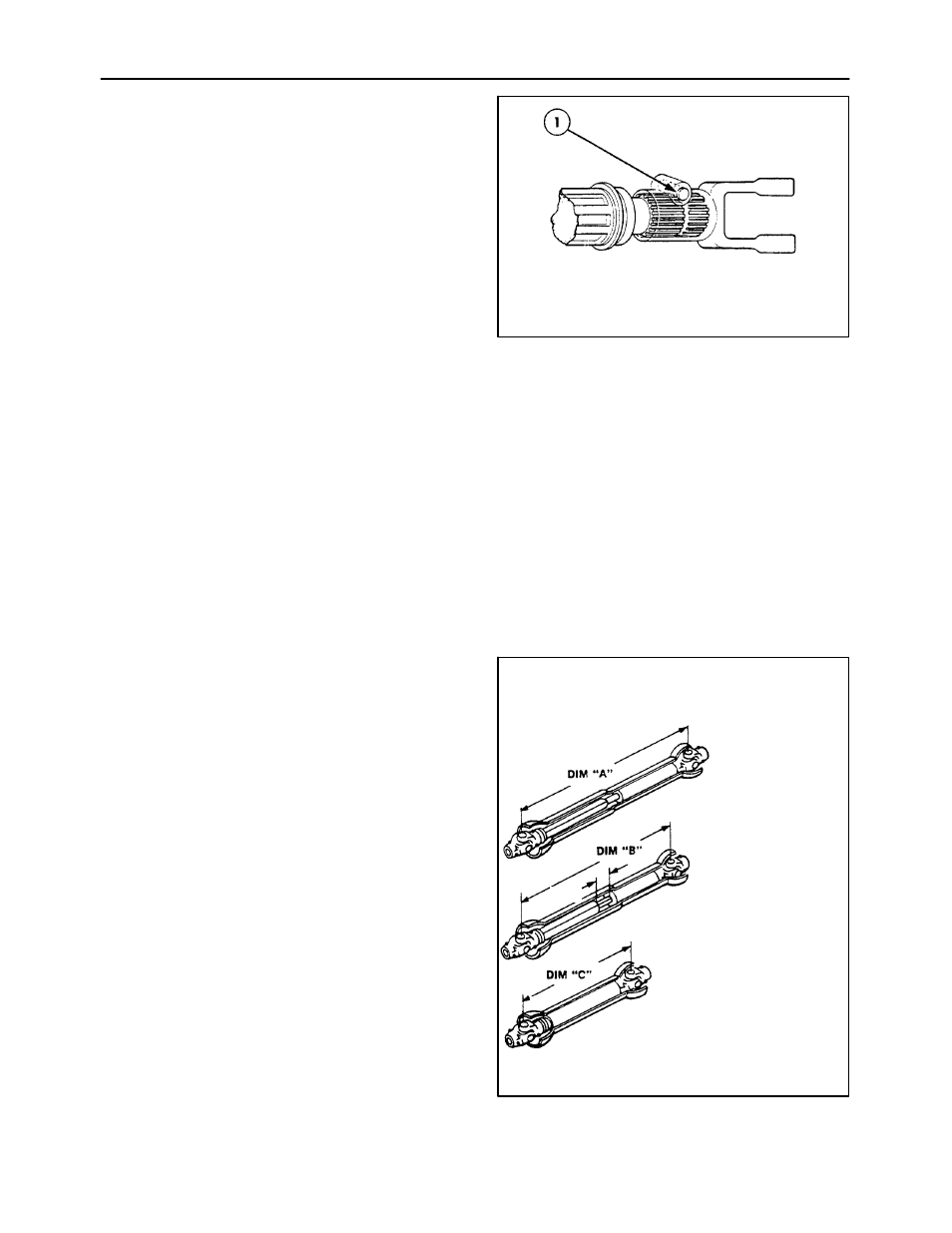

Pull drive halves until fully

extended, just before they

come completely apart. This

is dimension A.

From dimension A, subtract

150 mm (6”) establishing

dimension B.

IMPORTANT: Never operate

equipment with driveline

extended past dimension B.

IMPORTANT: Never operate

equipment with driveline

collapsed past dimension D.

Push drive halves together

as far as possible. This is

dimension C. Add 25 mm (1”)

to dimension C to establish

dimension D.

150 mm

DIM “D” EQUALS

DIM “C” + 25 mm (1”)

(6”)

109