Buhler 2180 User Manual

Page 129

SECTION 2 - OPERATION

2-83

LOW PRESSURE RETURN CIRCUIT

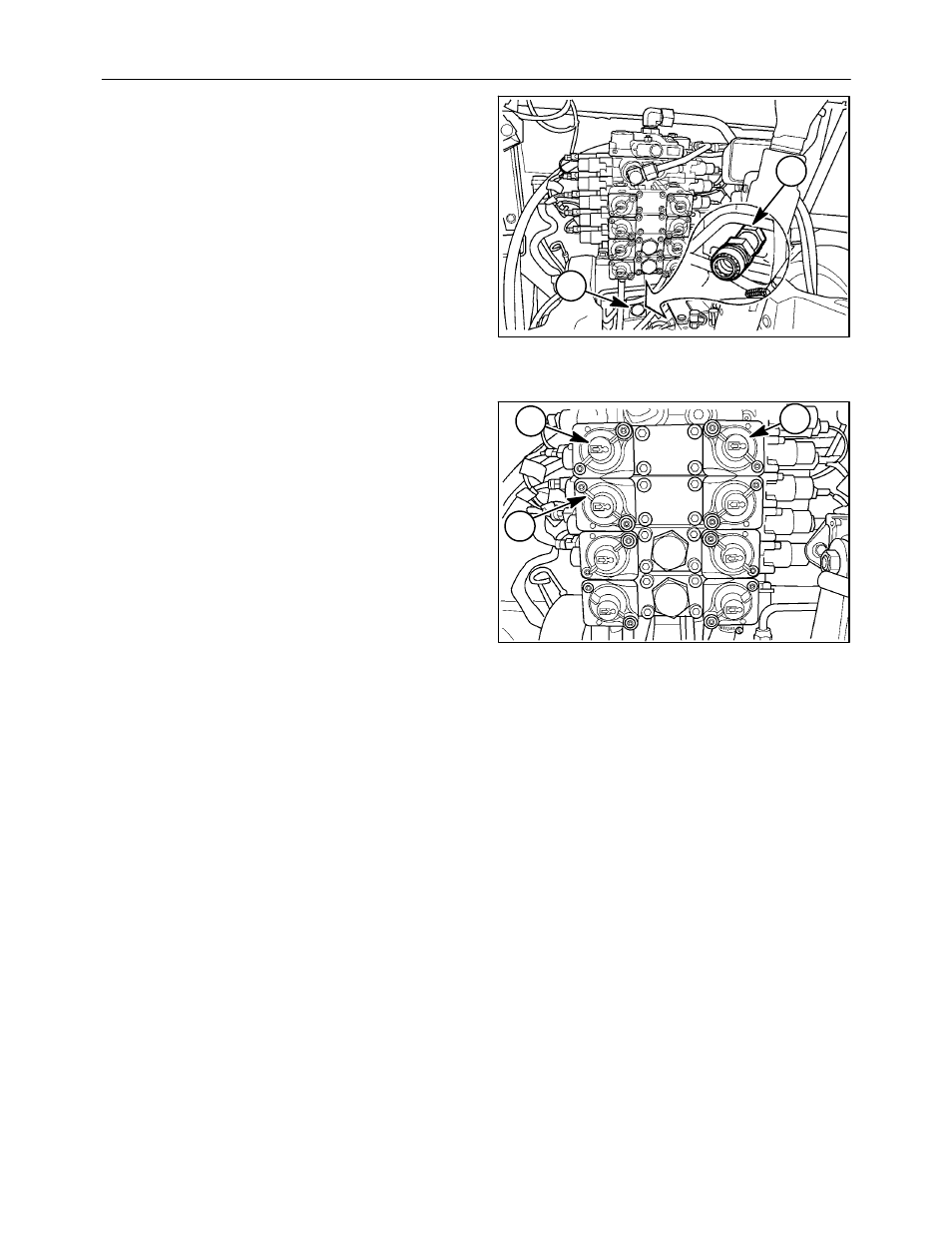

A low pressure return circuit is available by removing

the (1-1/16) - 12 ORB threaded plug, 1, and installing

a low pressure return kit, 2, P/N 86031849. The low

pressure return circuit will reduce back pressure in

the remote hydraulic return line which will result in

more efficient hydraulic motor operation. The return

circuit can also be used in applications where low

return oil pressure is desired to improve implement

operation such as orbit motor case drain lines.

Connect the return line from the hydraulic motor or

implement to the coupler.

NOTE: Connectors and couplers are available from

your authorized dealer.

2

1

123

QUICK COUPLERS

Each control valve has a pair of self-sealing,

leverless quick couplers to facilitate remote cylinder

connection. These couplers also permit remote

cylinder hoses to be pulled from the coupler if an

implement should become disconnected from the

tractor. The left couplers, 1, are identified by an

extended cylinder symbol containing an arrow

pointing in the direction of cylinder travel molded on

the cover. The right couplers, 2, are identified by a

retracted cylinder symbol containing an arrow

pointing in the direction of cylinder travel molded on

the cover. The covers pivot open by pressing on tab

3, to expose the quick coupler.

The covers are color coded (top) gray, brown, blue,

green (bottom) to correspond to the control switches

in the cab console.

The couplers will accept standard (1/2″ )SAE or ISO

tips. The couplers can be connected or disconnected

under pressure. Disconnect pressure is proportional

to system pressure. Increased system pressure will

require increased force to disconnect the couplers.

To connect a remote cylinder hose, open the coupler

dust cover. Clean, then insert the male coupler

making sure the coupler is correctly seated.

Actuate the remote valve to supply hydraulic

pressure which will complete the hydraulic coupling

of the tractor and implement.

To ease removal and installation of the couplers,

relieve the pressure in the system. Securely support

the implement. Make sure no one will be injured by

moving equipment when relieving pressure in the

system. Move the control switch to the float position

with the engine running. This will relieve the

pressure. Turn the engine off with the control switch

still in float. After the engine is shut down return the

control switch to the neutral position. The couplers

can now be connected or disconnected with minimal

pressure and effort.

2

3

1

124