Buhler 2180 User Manual

Page 172

SECTION 2 - OPERATION

2-126

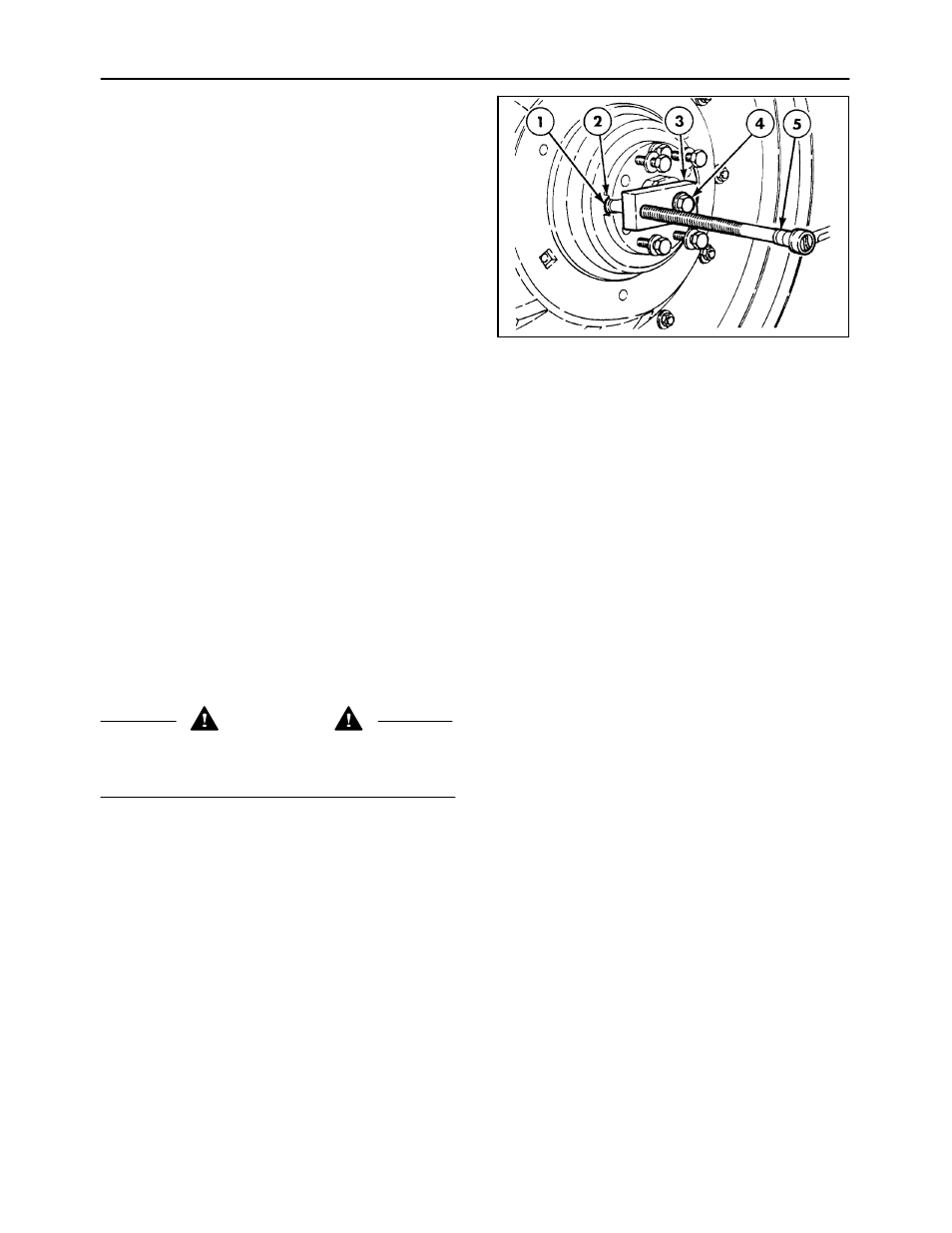

An optional wheel adjustment tool, P/N 9824982, is

available to move the loosened wheel in or out as

required. To use the tool, slide the stepped end, 1,

into the notch, 2, between the wedges. Attach the

block, 3, to the axle with one of the removed wedge

bolts, 4. Turn the adjusting bolt, 5, in or out to move

the wheel assembly.

NOTE: The tool is available through your authorized

dealer.

Set the wheel to the desired position on the shaft.

Remove the pusher bolts and replace them in the

outer holes, 2, Figure 180.

Tighten the six wedge retaining bolts in increments of

68 N·m (50 ft.-lbs.) until a final torque of 391 N·m (290

ft.-lbs.) is achieved.

IMPORTANT: The wedges must be pulled tight

evenly.

Repeat the procedure on the other wheel, making

sure that both rear wheels are the same distance

from the ends of the axle shafts.

NOTE: Check the torque of all six wedge retaining

bolts on each wheel after driving the tractor for 200

m (200 yards), after 1 hour, and 10 hours operation

and thereafter at the 50-hour service intervals.

186

ADJUSTING REAR WHEELS

WARNING

Tractor wheels are very heavy. Handle with care

and make sure, when stored, that they cannot fall

and cause injury.

NOTE: When changing from one track width setting

to another, it may be necessary to interchange the

left- and right-hand wheel assemblies. If so, be sure

that the “V” of the tire tread remains pointing in the

direction of forward travel.

Rear wheel track adjustment is effected by changing

the position of the disc, and/or wheel rim, relative to

the rear axle as shown in Figures 178 and 179.

In each position, a range of track settings may be

achieved by moving the wheel assemblies in or out

on the axle shafts.

To change wheel position, follow all steps outlined in

“Rear Wheel Track Adjustment.”