Buhler 2180 User Manual

Page 173

SECTION 2 - OPERATION

2-127

Adjusting Pressed Steel Wheel

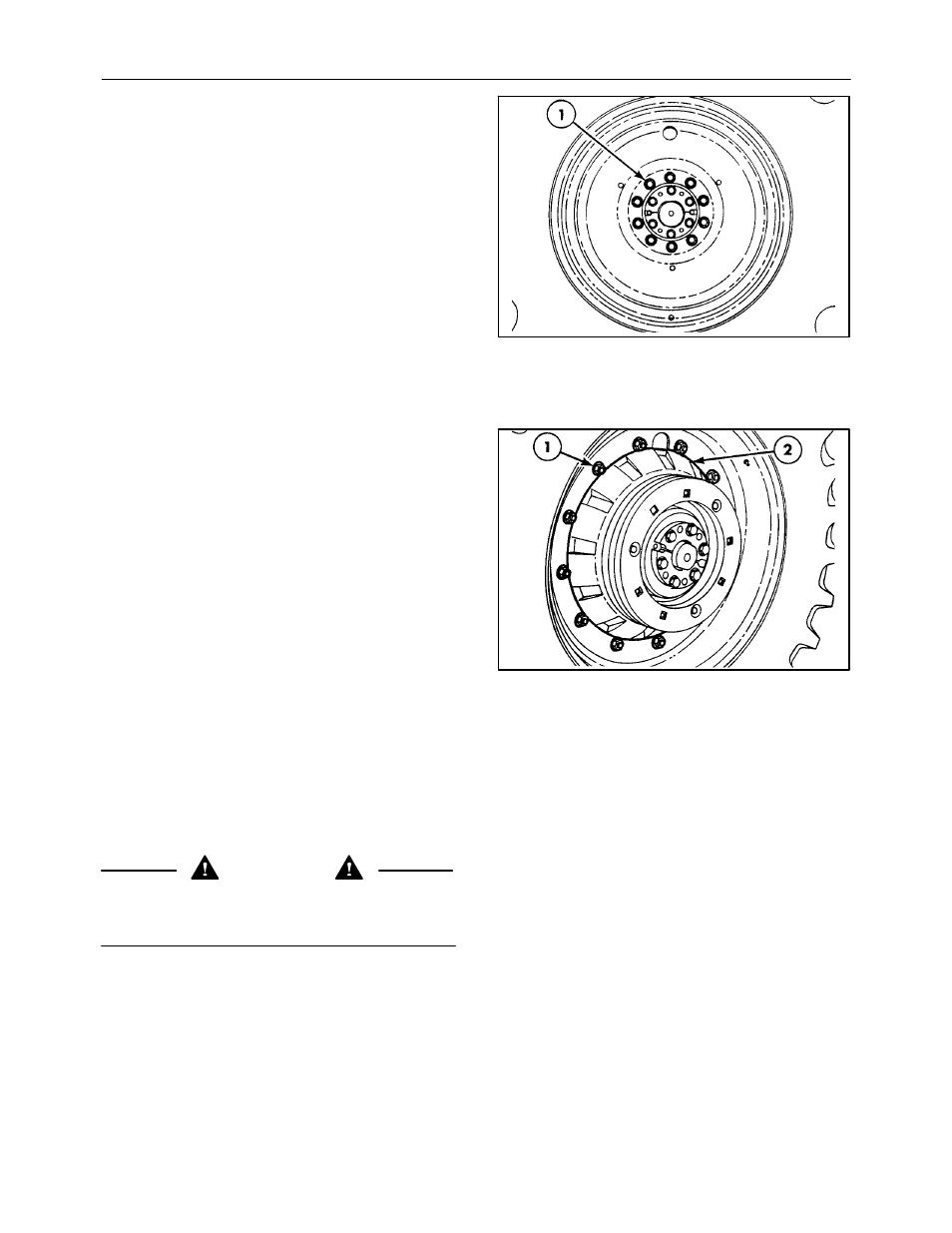

After the rear axle is jacked up and blocked, remove

the disc to hub bolts, 1. Using a suitable lifting device,

remove the wheel and store the wheel and tire where

it won’t fall over. Repeat the procedure on the

opposite wheel and install where the first wheel was

removed.

Torque the disc to hub bolts to 800 N·m (590 ft.-lbs.)

in 68 N·m (50 ft.-lbs.) increments using a diagonal

pattern.

NOTE: Check bolt torque after driving the tractor for

200 m (200 yards), after 1 hour, and 10 hours of

operation and thereafter at the 50-hour service

intervals.

187

Adjusting Cast Center Wheel

After the rear axle is jacked up and blocked, remove

the disc to rim attaching hardware, 1. Remove the

wheel using a suitable lifting device and store where

it won’t fall. Repeat this procedure on the opposite

rim and install on the first disc. If the discs, 2, are to

be switched, remove wheel weights first, then

position discs as required.

Reinstall the rim and weights and tighten all bolts and

nuts.

Repeat the procedure on the other wheel.

Tighten the rim to disc retaining nuts uniformly in an

alternate pattern, 68 N·m (50 ft.-lbs.) at a time, until

a torque of 596 N·m (440 ft.-lbs.) for Grade 8 bolts is

obtained, is obtained.

NOTE: Check hardware torque after driving the

tractor for 200 m (200 yards), after 1 hour, and 10

hours operation and thereafter at the 50-hour service

intervals.

WARNING

Never operate the tractor with a loose wheel or

rim. Always tighten the bolts to the specified

torque and check them frequently.

188