9eliminating faults, 10 technical specifications – Festo Параллельный захват HGPP User Manual

Page 29

HGPP-...-A

Festo HGPP-...-A 0110a English

29

9

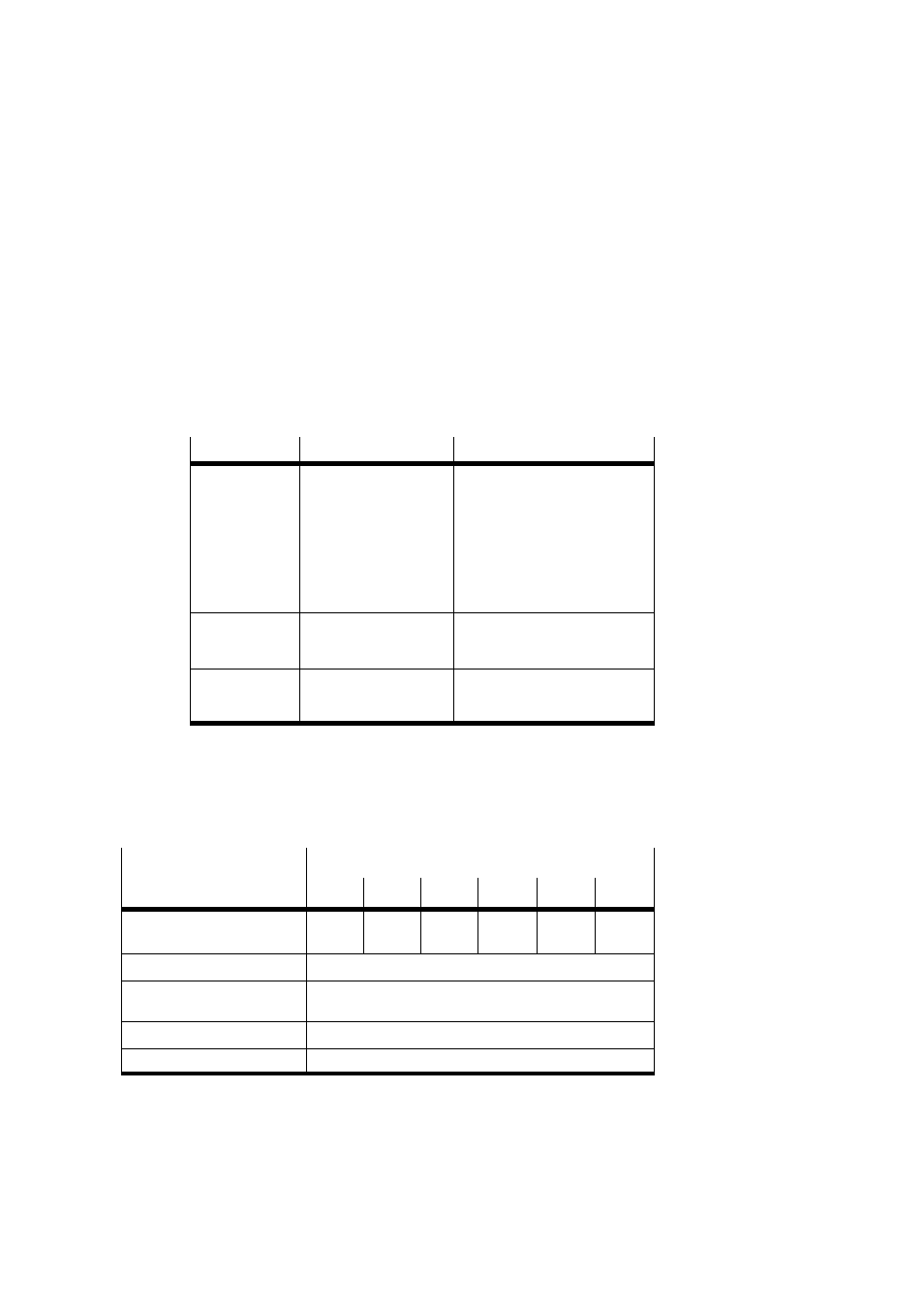

Eliminating faults

Fault

Possible cause

Remedy

Gripper cannot

hold mass firmly

– Mass too large

– Input pressure too low

– Centre of pressure of

gripper fingers too far

outside

– Gripping only by force of

reset spring in wrong

direction of gripping

– Select larger gripper

– Increase input pressure to maxi-

mum permitted value

– Move centre of pressure further

inwards

– Use direction of gripping pre-

scribed

Sensor does not

show gripping

status

– Sensor incorrectly ad-

justed

– Cable fracture

– Check position and calibration of

sensor

– Replace sensor cable

Gripper does not

open/close

– Compressed air not ap-

plied

– Gripper defective

– Check compressed air connec-

tions

– Return gripper to Festo

Fig. 26

10

Technical specifications

Type

HGPP-

10-A-...

12-A-... 16-A-...

20-A-...

25-A-...

32-A-...

Part no.

525658-

525660

187867-

187869

187870-

187872

187873-

187875

525661-

525663

525664-

525666

Design

Double-piston precision gripper

Medium

Filtered, lubricated or non-lubricated compressed air

(filter fineness min. 40 ìm)

Mounting position

As desired

Permitted operating pressure

2... max. 8 bar (control range at 23 °C; without spring pressure)