955c brik for pneumatic cylinders – AMETEK 1986XPJ Explosion Proof Resolver User Manual

Page 47

47

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

AUTOMATION & PROCESS

TECHNOLOGIES

955

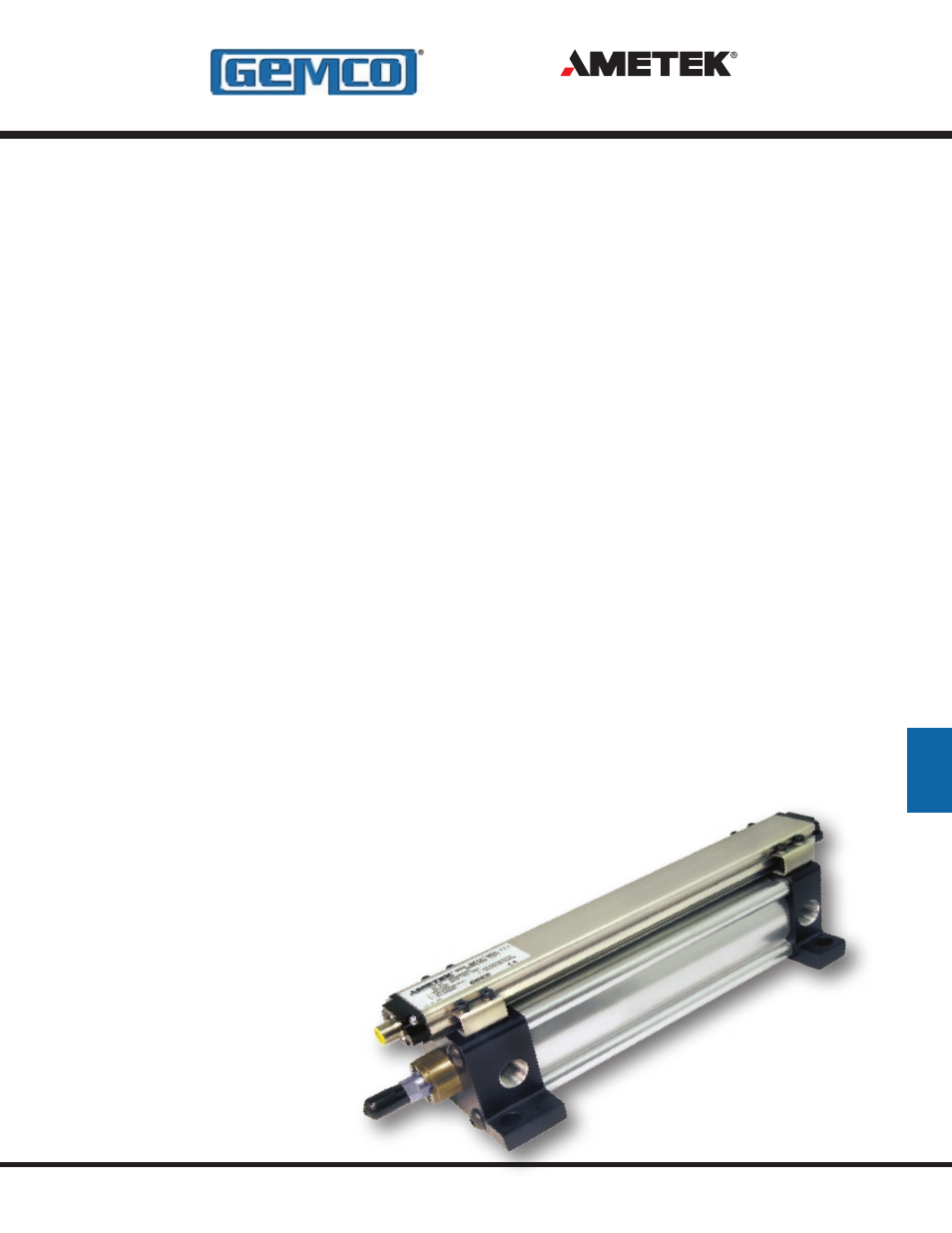

With the demand for automation greater than ever, the

need to replace limit and zone sensors on pneumatic

cylinders with continuous feedback has become obvious.

Speeding up and improving your process is what you

need in order to stay competitive. Knowing your exact

position at any given moment is essential to that end.

Replace your existing limit sensors with the GEMCO

955C BRIK GEN III for continuous position feedback

with your choice of Analog, Digital, or Quadrature

outputs. The

955C BRIK GEN III senses the magnet

located in your existing pneumatic cylinder and uses it to

relay absolute positioning information to the machine’s

controller. The

955C BRIK GEN III can be retro-fitted to

cylinders in the field using standard mounting brackets

or your own customized solution. The

955C solution has

no moving parts to wear out. Magnetostrictive technol-

ogy is used to “see” through the aluminum extrusion and

detect the position of the magnet mounted inside the

cylinder.

Three versions of the

955C BRIK GEN III are available.

The

955CA offers analog output in either voltage or

current with your choice of 0 to 10 VDC, 10 to 0 VDC, 4

to 20mA, or 20 to 4mA. The unit can easily be reconfig-

ured in the field from a 0-10 VDC to a 10-0 VDC or 4-20

mA to a 20-4 mA output.

The

955CD is designed for digital output with choice of

Control Pulse, Start/Stop Pulse, or Variable Pulse output.

The Quadrature output from the

955CDQ allows wiring

directly to any incremental encoder input card, with-

out the need for a special converter module or a PLC

interface card. The

955CDQ can be ordered with 1-9999

cycles per inch of output resolution in lengths of 5 to 180

inches. The transducer features an input to re-zero the

probe “on-the-fly”. Another unique feature is the “burst”

mode. An input on the transducer triggers a data trans-

fer of all the incremental position data relative to the set

zero position. This can be used to achieve

absolute position updates when power is

restored to the system, eliminating the

time-consuming need to “re-home” the

machine.

The

955C BRIK GEN III has truly unique features. The first

one being the LDT’s auto-tuning capability: the ability to

sense a magnet within the pneumatic cylinder and adjust its

signal strength accordingly.

Another feature is that the analog output is programmable

over the entire active stroke length. The active stroke area

of the LDT lies between the Null Zone and the Dead Band.

There is also a diagnostic LED located at the connector to

minimize setup time and troubleshooting. The LED is green

in normal operation. Red will indicate no magnet present

or that the magnet has moved out of sensing range. Yellow

is an indication the magnet is out of the programmed active

range or if no interrogation signal is detected.

The enclosure comes standard as IP67; however, up-

grading to IP68 is available as an option so the LDT can

be used in wet environments.

Note: The Pneumatic cylinder must have a magnet in order

to work. Each cylinder manufacturer uses different types

of magnets. In most cases the cylinder supplier installs the

magnet so that the South Pole is facing out. To date, we

have successfully worked with most brands of pneumatic

cylinders. Consult AMETEK APT for a list of compatible

cylinder manufacturers. Call 800.635.0289 to speak with

a Sales Engineer.

955C BRIK for Pneumatic Cylinders

- 1986 MD Mill Duty Housing 1986H Servo Mount Resolver 1986GG Multi Turn Dual Resolver 1986G 3 1986F Standard Block Style Resolver 1986E 100mm Face Mount Resolver 1986D 3 1986C 2.06 1986B 2.25 1986A Standard Foot Mount Resolver 956 Blok Housing Option 955S Smart Brik LDT 955LC Brik LDT 955DQ Brik LDT 955D LDT 955C Brik 955A Brik LDT 955 eBrik 953 VMAX LDT 952 BlueOx LDT 950 MD Mill Duty Housing LDT 950IS Intrinsically Safe LDT