950md mill-duty housing – AMETEK 1986XPJ Explosion Proof Resolver User Manual

Page 14

14

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

AUTOMATION & PROCESS

TECHNOLOGIES

950MD

NPT conduit port for wiring to the LDT or optionally

an MS connector can be installed for the external

wiring. Use of the MS connector will require that

the LDT also have a connector on it in lieu of a

potted cable. This will allow for a quick connect at

the LDT head internally and on the 950MD head

externally. The 950MD head is sealed with O-rings

and also contains two threaded air purge openings

that are plugged but available for use to air cool

the LDT head with filtered and regulated air. By

removing the plugs and installing the proper size

air fittings, you can cool the head electronics for

high temperature applications. An optional Vortex

air cooler may also be specified for the head and/or

barrel or an optional water jacket for the LDT can be

supplied. See the 950MD dimension drawings for

further details

.

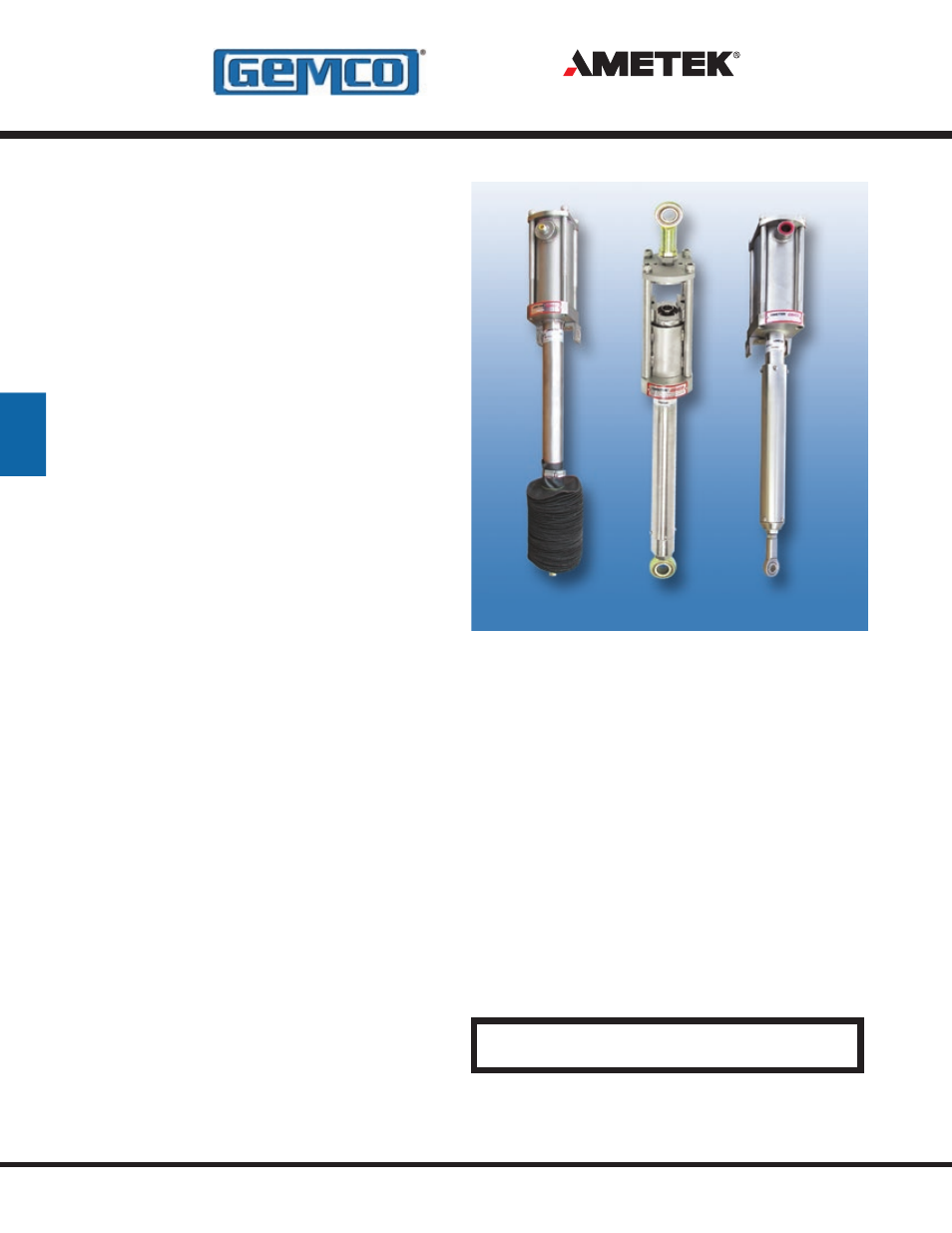

950MD Mill-Duty Housing

Optional Water-Cooled

Head Assembly

Consult Factory if installing

950IS into 950MD Housing

Optional

Bellows Boot

Optional

Stainless Boot

Due to the fact that the standard Mill-Duty Housing

has a mechanical stroke identical to the LDT

active stroke, no physical over-stroke exists. If

it is possible that the machine being coupled to

can extend/retract beyond the stroke supplied,

damage to the Mill-Duty Housing and possibly to the

machine might occur. To compensate for this we

call out fully retracted/fully extended over-stroke

dimensions for the Mill-Duty Housing. These values

are essentially the additional stroke length added to

the Mill-Duty Housing. The reason they are called

out separately is to alert the user that when entering

these areas, they are out of the LDT active stroke

area. If an extended over-stroke is specified, the

LDT must be ordered with a Dead Band of 5” + X

(extended stroke value). If a retracted over-stroke

is specified, the LDT must be specified with a Null

value of 2” + Y (retract over-stroke value).

The Mill-Duty Housing offers either a conduit

entrance for hard wiring directly to the LDT within

the head or an external connector and mate. The

connector attaches to the LDT inside of the housing

via a small pigtail connector within the head.

Detailed Product Description

and Materials of Construction

The 950MD consists of a 304 Stainless Steel body,

barrel, piston, head and trunnion mount bracket.

The standard 1/2” diameter rod end with mounting

bolt, the 3/4” diameter trunnion mounting bolt, and

some of the optional MS connectors on the head

are the only items that are not Stainless Steel on the

standard assembly. This is also true of the optional

3/4” diameter front and rear rod ends with their

mounting bolts. These rod ends and all mounting

bolts can be ordered in Stainless Steel as an option.

The 12mm Euro connector options C3 and C4 come

standard in Stainless Steel. Consult the factory for

further details.

The 950MD head assembly is removable to allow

installation of a rod style LDT that will screw into

the standard 3/4” - 16 x 1.00 mounting thread. An

optional Metric thread of M18 X 1.5 can also be

supplied upon request. The head contains a 1/2”

- 1986 MD Mill Duty Housing 1986H Servo Mount Resolver 1986GG Multi Turn Dual Resolver 1986G 3 1986F Standard Block Style Resolver 1986E 100mm Face Mount Resolver 1986D 3 1986C 2.06 1986B 2.25 1986A Standard Foot Mount Resolver 956 Blok Housing Option 955S Smart Brik LDT 955LC Brik LDT 955DQ Brik LDT 955D LDT 955C Brik 955A Brik LDT 955 eBrik 953 VMAX LDT 952 BlueOx LDT 950 MD Mill Duty Housing LDT 950IS Intrinsically Safe LDT