AMETEK 1986XPJ Explosion Proof Resolver User Manual

Page 44

44

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

AUTOMATION & PROCESS

TECHNOLOGIES

955

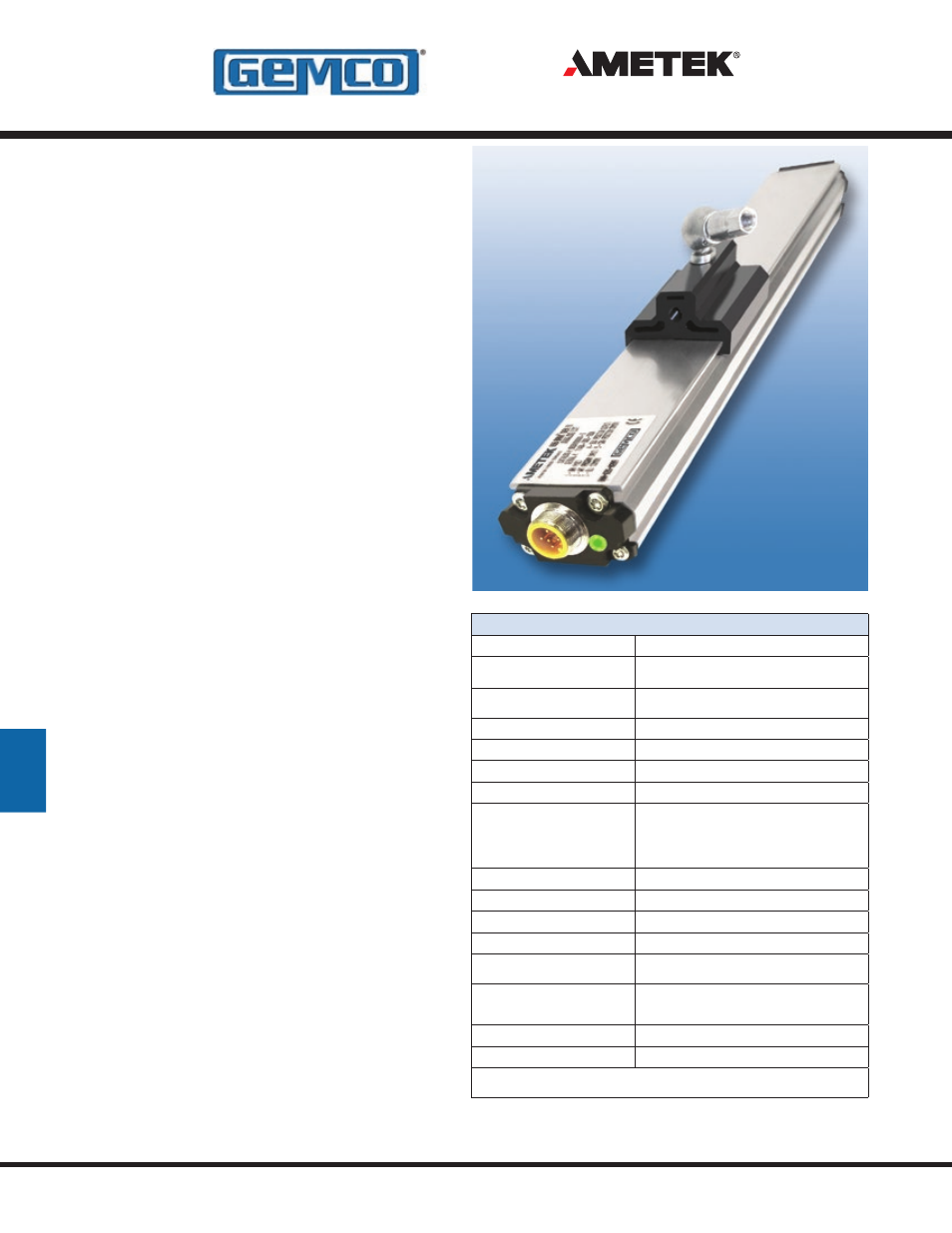

955DQ BRIK Gen III Magnetostrictive LDT

In A Low Profile Package

The 955DQ BRIK is an accurate, auto-tuning, non-

contact linear displacement transducer in an

economical, low profile package with direct quadrature

output.

This new method of interfacing magnetrostrictive

transducers offers an interface as common as

analog but with the speed and accuracy of pulsed

type signaling. The Gemco 955DQ linear transducer

provides quadrature output directly from the transducer

to the controller. The output from the transducer can be

wired directly to any incremental encoder input card,

without the need for a special converter module or a

PLC interface card designed specifically for use with a

pulsed output magnetostrictive transducer.

The streamlined anodized aluminum extrusion houses

the sensing element and electronics. The BRIK with

quadrature output is a self-contained unit and does

not have a can or head assembly. All of the electronics

are incorporated in the transducer which is less than

one inch deep. The magnet slide is designed to move

effortlessly along the transducer in a guide track or a

floating magnet assembly can be positioned above the

unit.

The 955DQ BRIK has a few truly unique features. First,

the LDT has auto-tuning capability. This is the abiliy to

sense a magnet other than the standard slide magnet

and adjust its signal strength accordingly. Another

feature is a diagnostic LED located at the connector end

of the probe that remains green when a good magnet

signal is present and power is normal. The LED turns

red when there is no magnet present or the magnet

assembly is out of the sensing area.

The 955DQ LDT can be ordered with 1-9999 cycles per

inch of output resolution in lengths of 5 to 180 inches.

The transducer features an input to re-zero the probe

“on-the-fly”. Another unique feature is the “burst” mode.

An input on the transducer triggers a data transfer of all

the incremental position data relative to the customers

set zero position. This can be used to achieve absolute

position updates when power is restored to the system,

eliminating the time consuming need to “re-home” the

machine.

Specifications

Input Voltage

13.5 to 30 VDC

Current Draw

2.5 Watts Maximum,

120mA @ 15 VDC Typical

Output

Quadrature Output A+, A-, B+, B-, Z+, Z-

Line Drivers: 5V or Input Power

Resolution

0.001”

Linearity

+/- 0.05% of Stroke

Repeatbility

+/- 0.006% of Full Stroke

Hysteresis

+/- 0.02% of Full Scale

Update

50” or less

51” to 100”

101” to 150”

151” to 180”

1ms (Stroke Lengths 5” to 50”)

2ms (Stroke Lengths 51” to 100”)

3ms (Stroke Lengths 101” to 150”)

4ms (Stroke Lengths 151” to 180”)

Operating Temperature

-20° to 70° C

Span Length

5” to 180”

Null Zone

3.00”

Dead Band

2.00”

LED

Green = Power is applied and magnet is present

Red = Fault, magnet is in the Dead Band or lost

Connector

Standard 12 Pin Micro (Option E)

12mm Euro Connector

or 10 Pin HRS (Option H)

Approvals

CE

Enclosure

IP67, IP68 Optional (Connector Option E Only)

Specifications are subject to change without notice.

Specifications are based on a typical 36” LDT.

- 1986 MD Mill Duty Housing 1986H Servo Mount Resolver 1986GG Multi Turn Dual Resolver 1986G 3 1986F Standard Block Style Resolver 1986E 100mm Face Mount Resolver 1986D 3 1986C 2.06 1986B 2.25 1986A Standard Foot Mount Resolver 956 Blok Housing Option 955S Smart Brik LDT 955LC Brik LDT 955DQ Brik LDT 955D LDT 955C Brik 955A Brik LDT 955 eBrik 953 VMAX LDT 952 BlueOx LDT 950 MD Mill Duty Housing LDT 950IS Intrinsically Safe LDT