955 ebrik – AMETEK 1986XPJ Explosion Proof Resolver User Manual

Page 35

35

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

AUTOMATION & PROCESS

TECHNOLOGIES

955

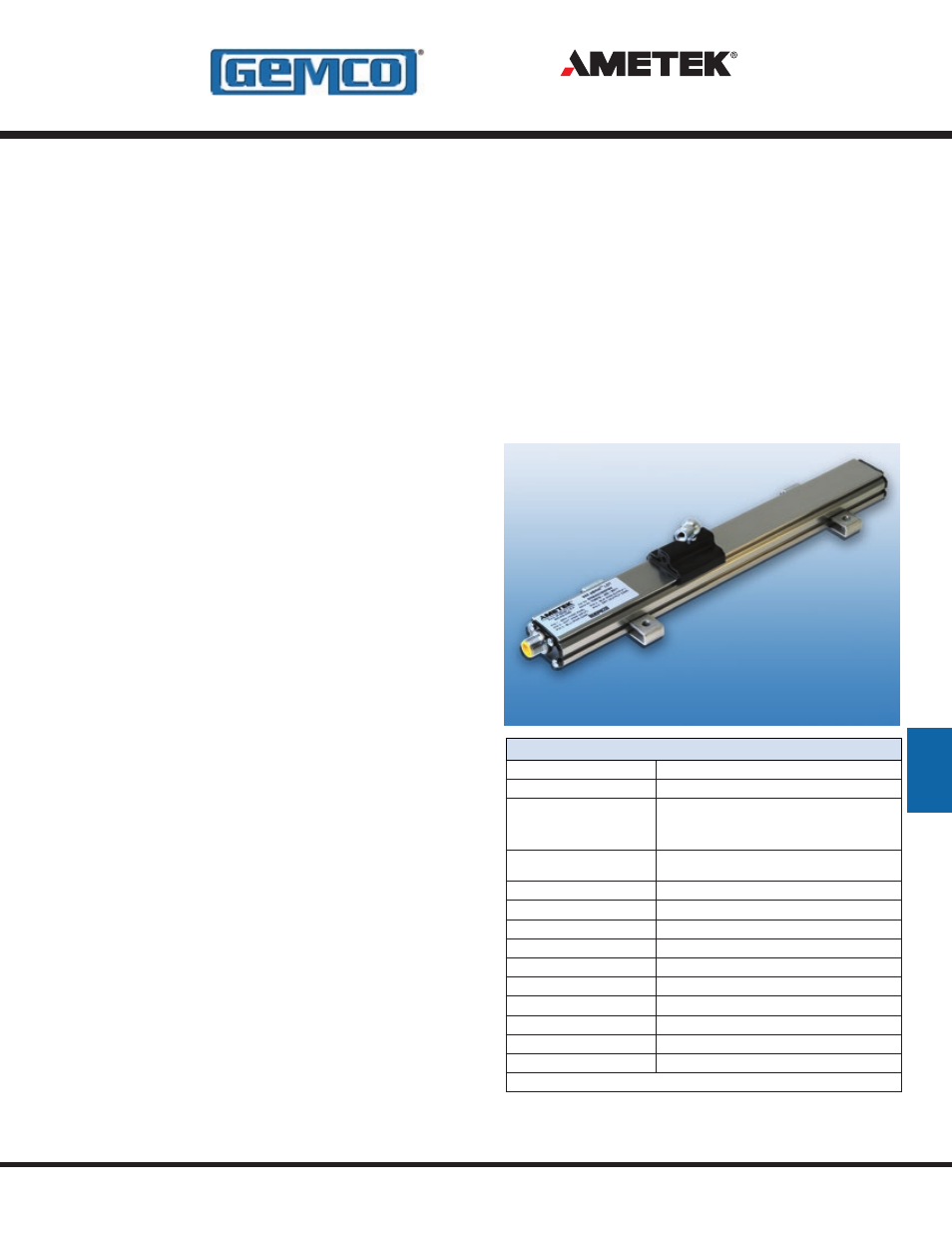

The transducer can be mounted vertically or horizon-

tally using our mounting feet which slide on the lower

part of the extrusion and clamp down when tightened.

This packaging provides a compact and easy method of

mounting for machine builders.

The 955 eBrik™ is designed for applications where eco-

nomical continuous feedback is necessary. The sensor

can be a cost effective replacement to linear potentiom-

eters, limit and proximity sensors.

Applications include presses, blow molding, injection

molding, extruding, roll positioning, tire press, and many

more.

955 eBRIK

TM

High Resolution

Magnetostrictive LDT In A Low

Profile Package

The 955 eBrik™ is an accurate, programmable zero and

span, auto-tuning, non-contact linear position sensor in

an economical, low-profile package. The sensor utilizes

our field-proven Magnetostrictive technology to provide

absolute position, repeatable to .001% of the sensing

distance. The 955 eBrik™ is a cost effective linear sens-

ing solution.

The streamlined anodized aluminum extrusion houses

the sensing element and electronics. The magnet moves

over the sensing element that determines the position

and converts it to a readable output. The 955 eBrik™ is

a self-contained unit and does not have a “can” or head

assembly. All of the electronics are incorporated in the

transducer, which is less than one inch tall.

Units can be ordered in span lengths up to 72 inches

long in 1 inch increments. The slide magnet is designed

to move effortlessly along the transducer in guide tracks,

or a floating magnet assembly can be positioned above

the unit. A variety of hardware is available for attaching

the magnet slide to the moving portion of the process.

The transducer can be ordered with 0 to10 VDC or 4 to

20 mA output.

All units are provided with our standard 5 pin 12mm Euro

Micro connector, mounting feet and magnet assembly.

Mating cables are sold in various lengths and must be

ordered separately.

The 955 eBrik™ has a few truly unique features. One

feature is the LDT’s auto-tuning capability, the ability to

sense the distance between the magnet and the sens-

ing surface and adjust its signal strength accordingly. As

a bonus feature, the 955 eBrik™ offers Programmabil-

ity, the ability to rescale the Zero and Span positions

or invert the positions in the field. This is an optional

feature and must be called out at time of order under the

“Options” field. All units come fully programmed from the

factory, are 100% absolute, and do not require repro-

gramming unless desired. There is a unique diagnostic

that is built into the analog output on every unit. If there

is a loss of magnet, or if the magnet assembly moves

beyond the programmed range, the analog output will

transmit a fault voltage or current, warning the host con-

troller that it is out of range.

Specifications

Input Voltage

24 VDC +/- 20%

Current Draw

1.1w (44 mA typical)

Output

0 to 10 VDC

10 to 0 VDC

4 to 20 mA

20 to 4 mA

Non-Linearity

Less than +/- 0.03% of stroke,

or +/- 0.013” whichever is greater

Resolution

16 Bit (1 part in 65535)

Update Time

1 ms

Repeatability

.001%

Operating Temperature

-40° to 85° C

Span Length

1” to 72”

Null Zone

2.75”

Dead Zone

2.75”

Connectors

12mm Micro 5 Pin

Enclosure

IP67

Approvals

CE

Specifcations are subject to change without notice.

- 1986 MD Mill Duty Housing 1986H Servo Mount Resolver 1986GG Multi Turn Dual Resolver 1986G 3 1986F Standard Block Style Resolver 1986E 100mm Face Mount Resolver 1986D 3 1986C 2.06 1986B 2.25 1986A Standard Foot Mount Resolver 956 Blok Housing Option 955S Smart Brik LDT 955LC Brik LDT 955DQ Brik LDT 955D LDT 955C Brik 955A Brik LDT 955 eBrik 953 VMAX LDT 952 BlueOx LDT 950 MD Mill Duty Housing LDT 950IS Intrinsically Safe LDT