Gemco 955a brik gen iii – AMETEK 1986XPJ Explosion Proof Resolver User Manual

Page 40

40

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

AUTOMATION & PROCESS

TECHNOLOGIES

955

Specifications

Input Voltage

13.5 to 30 VDC

Current Draw

2.5 Watts Maximum,

120mA @ 15 VDC Typical

Output

0 to 10 VDC, 10 to 0 VDC, 4 to 20mA,

20 to 4mA

Resolution

Internal

Analog Output

0.001”

16 Bit (1 part in 65,535)

Linearity

+/- 0.05% of Stroke

Repeatbility

+/- 0.006% of Full Stroke

Hysteresis

+/- 0.02% of Full Scale

Update

50” or less

51” to 100”

101” to 150”

151” to 180”

1ms (Stroke Lengths 5” to 50”)

2ms (Stroke Lengths 51” to 100”)

3ms (Stroke Lengths 101” to 150”)

4ms (Stroke Lengths 151” to 180”)

Operating Temperature

-20° to 70° C

Span Length

5” to 180”

Null Zone

3.00”

Dead Band

2.00”

LED

Green = Power is applied and magnet is present

Red = Fault, magnet is in the Dead Band or lost

Yellow = Out of the active programmed range

Connector

Standard 5 Pin Micro

12mm Euro Connector

Approvals

CE

Enclosure

IP67, IP68 Optional

Specifications are subject to change without notice.

Specifications are based on a typical 36” LDT.

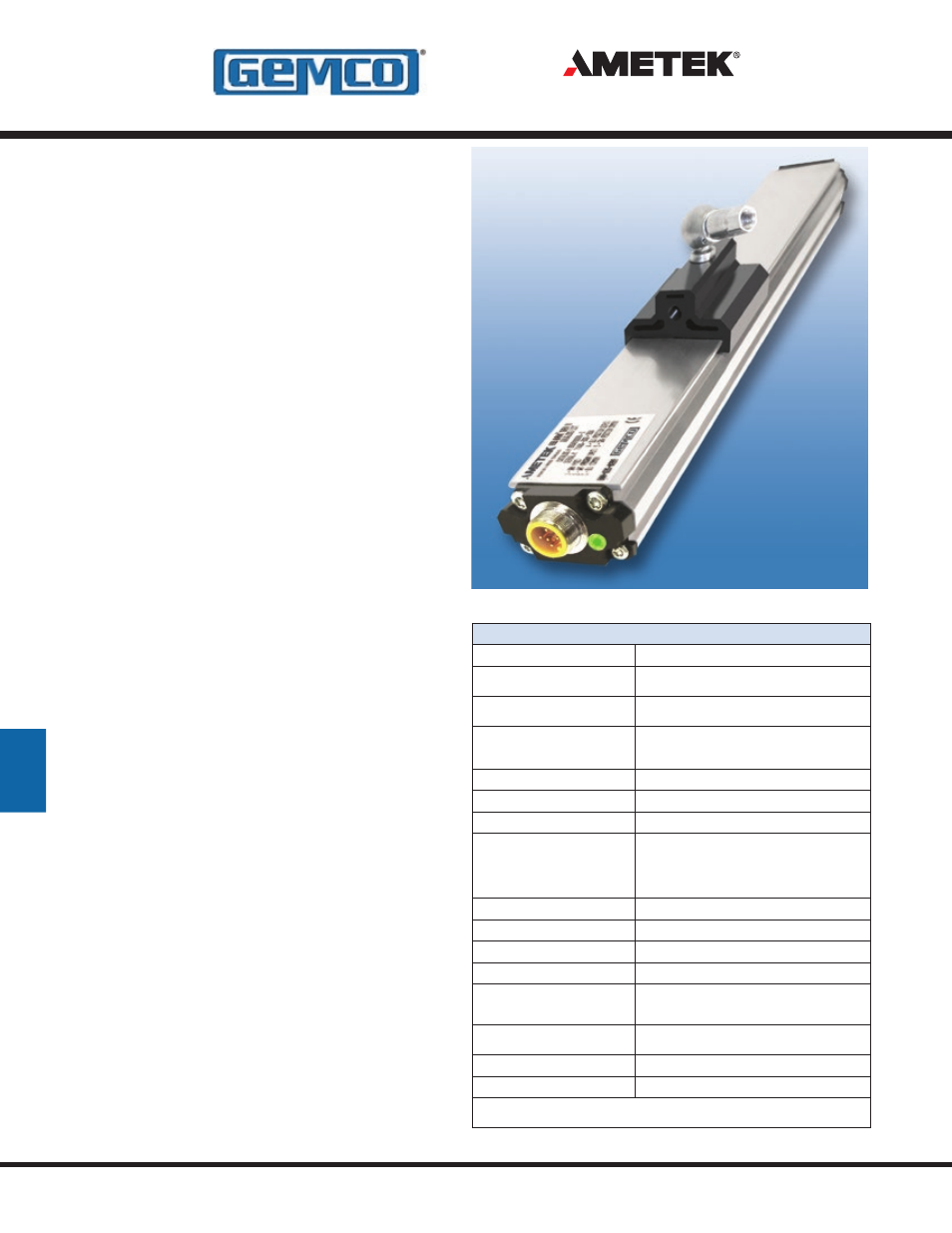

Gemco 955A BRIK Gen III

The 955A BRIK Gen III is an accurate

programmable, auto-tuning, non-contact, linear

displacement transducer in an economical, low

profile package. The transducer utilizes our field

proven magnetostrictive technology to give absolute

position, repeatable to .006% of the programmable

sensing distance.

The streamlined anodized aluminum extrusion

houses the sensing element and electronics. The

magnet moves over the sensing element that

determines the position and converts it to an analog

output. It can be ordered with a 0 to 10 VDC or

4 to 20mA output.

The 955A BRIK Gen III has a few truly unique

features. The first one is the LDT’s auto-tuning

capability, the ability to sense a magnet other than

the standard slide magnet and adjust its signal

strength accordingly. Another feature is the analog

output is programmable over the entire active

stroke length. The active stroke area of the LDT

lies between the Null and Dead zones. There is

a diagnostic LED located at the connector end of

the probe that remains green while a good magnet

signal is present and when the magnet is in the

programmed stroke area. The LED turns yellow

when the magnet is out of the programmed active

range, but still within the active stroke area. The

LED turns red and the output goes to 0 volts on

voltage output units, or 4mA on current output

units when there is no magnet present or when the

magnet is out of the sensing area.

The unit can easily be changed in the field from a

0 - 10 VDC to a 10 - 0 VDC or 4 - 20mA to a

20 - 4mA . As an added feature, the optional

differential analog output allows the distance

between two magnets to be measured.

The 955A BRIK is designed for applications where

economical continuous feedback is necessary. The

sensor can be a cost effective replacement to limit

switches, proximity sensors, linear potentiometers

and LVDT’s. Applications include presses,

blow molding, injection molding, extrusion, roll

positioning, dancer control and many more.

- 1986 MD Mill Duty Housing 1986H Servo Mount Resolver 1986GG Multi Turn Dual Resolver 1986G 3 1986F Standard Block Style Resolver 1986E 100mm Face Mount Resolver 1986D 3 1986C 2.06 1986B 2.25 1986A Standard Foot Mount Resolver 956 Blok Housing Option 955S Smart Brik LDT 955LC Brik LDT 955DQ Brik LDT 955D LDT 955C Brik 955A Brik LDT 955 eBrik 953 VMAX LDT 952 BlueOx LDT 950 MD Mill Duty Housing LDT 950IS Intrinsically Safe LDT