AMETEK 7014 Unifloat Level Float Sensors User Manual

B/w controls, Series 7014 unifl oat, Installation manual

B/W Controls

Series 7014

Unifl oat

®

Installation Manual

IMPORTANT

Just before fi nal installation into the tank and with the switches mounted inside the guide tube, slide the fl oat up and

down the tube. This will reset all the switches to their normal condition. If the Type “C” Reed Switch was ordered,

the common switch wire (C) in the UNIFLOAT is bare and is attached to the ground screw with a green wire.

RATINGS:

The factory assembled units are rated for operating pressures up to 500 PSI and temperatures of 0° to 250° F

(-19° to 121°C). For pressure tight applications pipe sealing compound should be used on the holder mounting

threads. It is best to install in an upright position, but can be mounted up to 30° from vertical. While some small

loads such as pilot lights may be operated directly from the switches, most applications will require control relays.

Conventional relays can be used, however, B/W relays have unique characteristics that make them desirable for

many applications. Diagrams are attached showing B/W recommended wiring for various relays in some typical

applications.

SWITCH ADJUSTMENT:

Refer to your order for details on the switch settings provided when the UNIFLOAT was shipped from the factory.

If different settings are desired, remove cover on holder. Do not remove any other fi ttings. Remove the internal

assembly consisting of the switches and common wire, (On Type “C” Reed Switch Only), terminal block, and

mounting plate. The set lengths for each switch actuation is measured from the bottom of the terminal block

mounting plate, and is 1.25” + longer than the set length measured from the bottom of the holder mounting threads,

based on a liquid with 1.0 specifi c gravity. Each switch is marked with the actuation point, and the differential travel

is 0.1 inch. Switch actuation will depend on the actual specifi c gravity of the liquid. See the tables below for set

length adjustments for liquids with specifi c gravities other that 1.0.

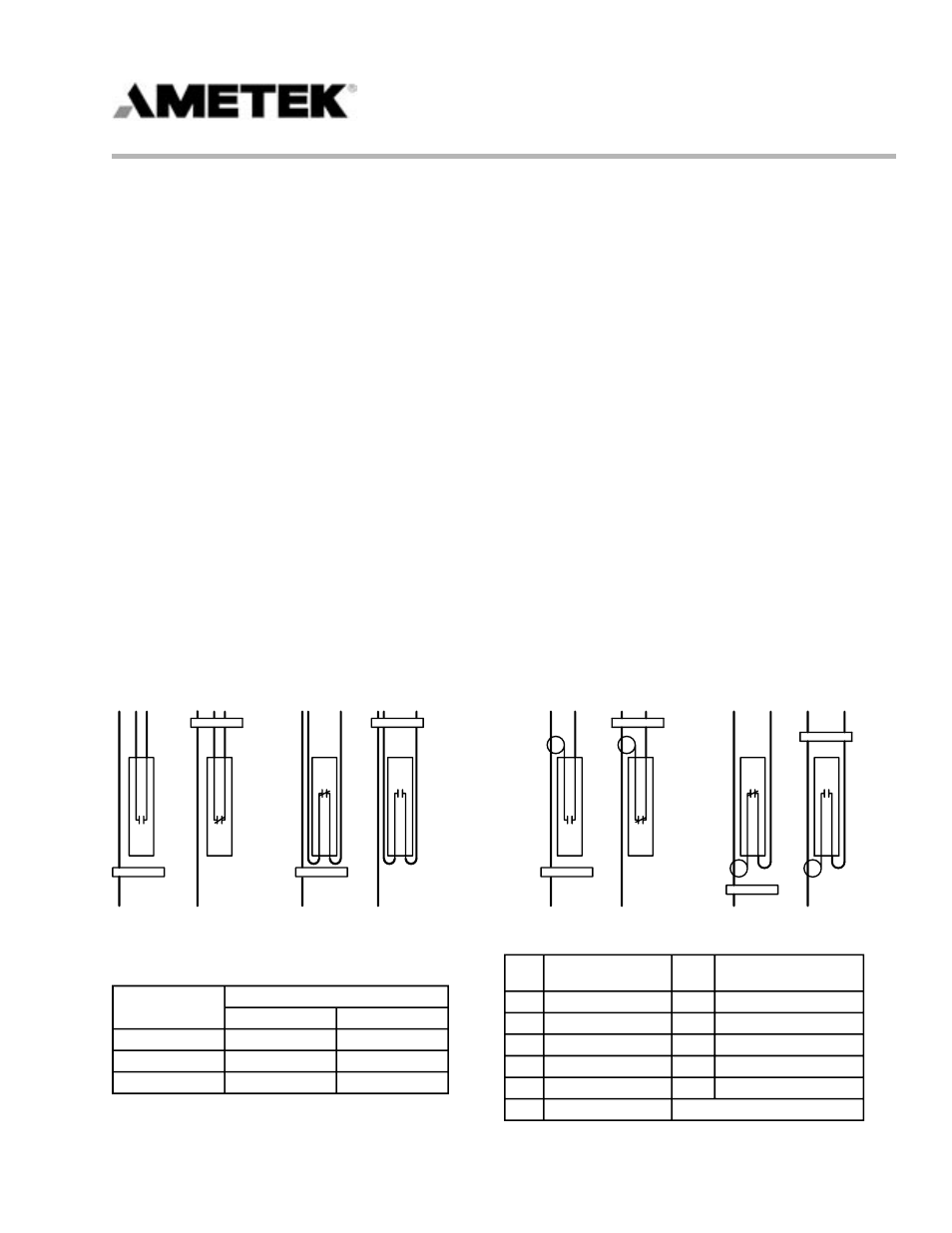

DIRECT OPERATION:

Switches close on the rising level.

FLOAT MAGNET

FLOAT MAGNET�

FLOAT MAGNET

FLOAT MAGNET

FLOAT MAGNET�

FLOAT MAGNET�

FLOAT MAGNET�

FLOAT MAGNET�

INVERSE OPERATION:

Switches close on the falling level.

SWITCH CONVERTION FROM DIRECT TO INVERSE:

In order to change a Type “I” or Type “C” switch from direct operation to inverse operation, rotate the switch 180°

end-to end. For Type “C” switch, re-attach to bare wire. For Type “I” switch, re-tape to the bare wire.

TYPE “I” SWITCH

TYPE “C” SWITCH

VOLTS

MAXIMUM CURRENT

AC

DC

25

440mA

400mA

50

220mA

200mA

120

90mA

80mA

REED SWITCH RATINGS

DIRECT OPERATION

INVERSE OPERATION

DIRECT OPERATION

INVERSE OPERATION

S.G.

SUBTRACT FROM

LENGTH

S.G.

ADD TO LENGTH

1.5

0.37 Inch

1.0

NONE

1.4

0.31 Inch

0.9

0.12 Inch

1.3

0.25 Inch

0.8

0.27 Inch

1.2

0.18 Inch

0.7

0.48 Inch

1.1

0.10 Inch

*0.65

0.62 Inch

1.0

NONE

*Recommended Minumum

SPECIFIC GRAVITY ADJUSTMENT