Appendix “d” - manual tuning 81, Open loop step response method 81, Appendix “d” - manual tuning – Red Lion TCU User Manual

Page 89

APPENDIX “D” - MANUAL TUNING

Open Loop Step Response Method

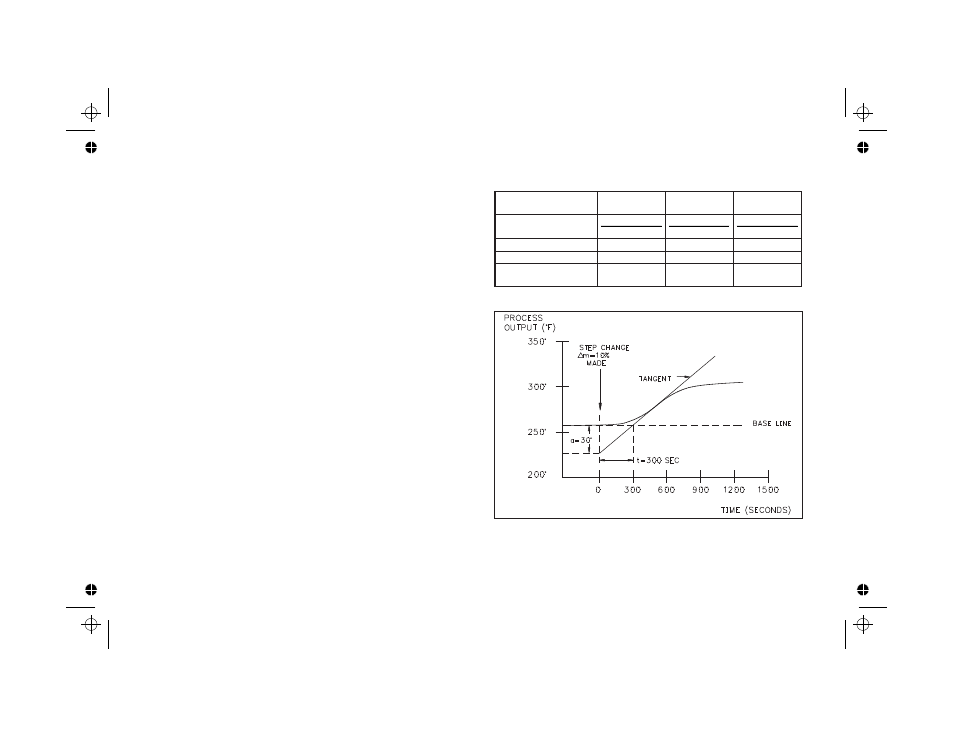

The Open Loop Step Response Method is a tuning procedure that does not

induce process oscillations. This method involves making a step change to

the process and observing the process reaction. A strip paper recorder or other

high resolution data logging equipment is required for this procedure. This

procedure requires that all disturbances to the process are minimized because

the data is influenced by these disturbances.

1) Connect a chart recorder to log temperature and set the paper speed

appropriate for the process.

2) Set the controller to manual (user) control mode.

3) Allow the process to stabilize (line out).

4) Make a step change of 10% or more in the controller output. It may be

necessary to increase the size of the step to yield a sufficient process

reaction curve.

5) Record the response of the process. Use the information from the table to

calculate the controller tuning values. The PID tuning parameters are

determined graphically from Figure 43, Process Reaction Curve. Draw a

vertical line at the moment the step change was made. Draw a line (labeled

tangent) through the process reaction curve at its

maximum upward slope.

Extend this line to intersect the vertical line.

Example

: From the Process reaction Curve

a = 30°, t = 300 sec, step = 10%, thermocouple range = 1700°F.

For fast response:

Prop

=

35.3%

Intt

=

900 sec

dert

=

120 sec

OPdP

=

15

Parameter

Fast

Response

Damped

Response

Slow

Response

Proportional Band (%)

20000a

Range

Step%

´

40000a

Range

Step%

´

60000a

Range

Step%

´

Integral Time (Sec)

3t

4t

5t

Derivative Time (Sec)

0.4t

0.4t

0.4t

Output Power

Dampening (Sec)

t/20

t/15

t/10

81

Figure 43, Process Reaction Curve