Pid control 63, Proportional band 63, Integral time 63 – Red Lion TCU User Manual

Page 71: Pid control

PID CONTROL

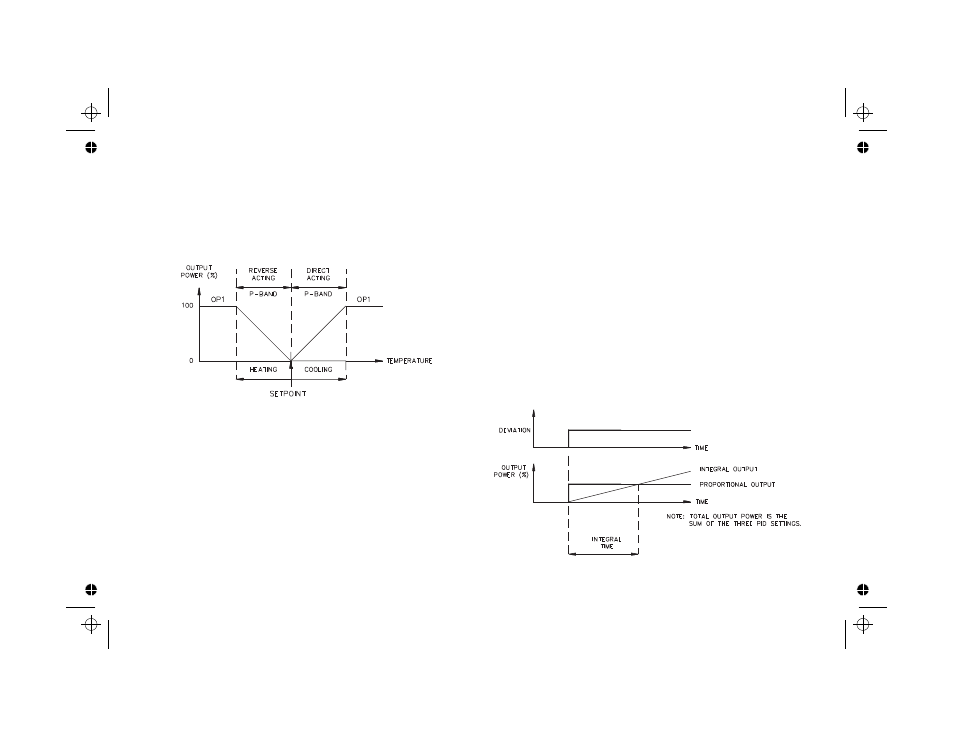

Proportional Band

Proportional band is defined as the “band” of temperature the process

changes to cause the percent output power to change from 0% to 100%. The

band may or may not be centered about the setpoint value depending upon the

steady state requirements of the process. The band is shifted by manual offset

or integral action (automatic reset) to maintain zero error. Proportional band

is expressed as percent of input sensor range.

Example

: Thermocouple type T with a temperature range of 600°C is used

and is indicated in degrees Celsius with a proportional band of 5%. This

yields a band of 600°C X 5% = 30°C.

The proportional band should be set to obtain the best response to a

disturbance while minimizing overshoot. Low proportional band settings

(high gain) result in quick controller response at expense of stability and

increased overshoot. Settings that are excessively low produce continuous

oscillations at setpoint. High proportional band settings (low gain) result in a

sluggish response with long periods of process “droop”. A proportional band

o f 0 . 0 % f o r c e s t h e c o n t r o l l e r i n t o O N / O F F c o n t r o l mo d e w i t h i t s

characteristic cycling at setpoint (See

ON/OFF Control

, page 66, for more

information).

Integral Time

Integral time is defined as the time, in seconds, in which the output due to

integral action alone equals the output due to proportional action with a

constant process error. As long as a constant error exists, integral action

repeats the proportional action every integral time. Integral action shifts the

center point position of the proportional band to eliminate error in the steady

state. The units of integral time are seconds per repeat.

Integral action (also known as “automatic reset”) changes the output

power to bring the process to setpoint. Integral times that are too fast (small

times) do not allow the process to respond to the new output value. This

causes over compensation and leads to an unstable process with excessive

overshoot. Integral times that are too slow (large times) cause a slow response

to steady state errors. Integral action may be disabled by setting the time to

zero. If time is set to zero, the previous integral output power value is

maintained.

If integral action is disabled, manual reset is available by modifying the

output power offset (“OPOF” initially set to zero) to eliminate steady state

errors. This parameter appears in unprotected parameter mode when integral

time is set to zero. The controller has the feature to prevent integral action

when operating outside the proportional band. This prevents “reset

wind-up”.

63

Figure 31, Proportional Band

Figure 32, Integral Time

Note: The Proportional band shift due to integral action

may itself be “reset” by temporarily setting the controller

into the ON/OFF control mode (proportional band =0).