Valve position option 58, Position mode valve control 58, Valve position option – Red Lion TCU User Manual

Page 66

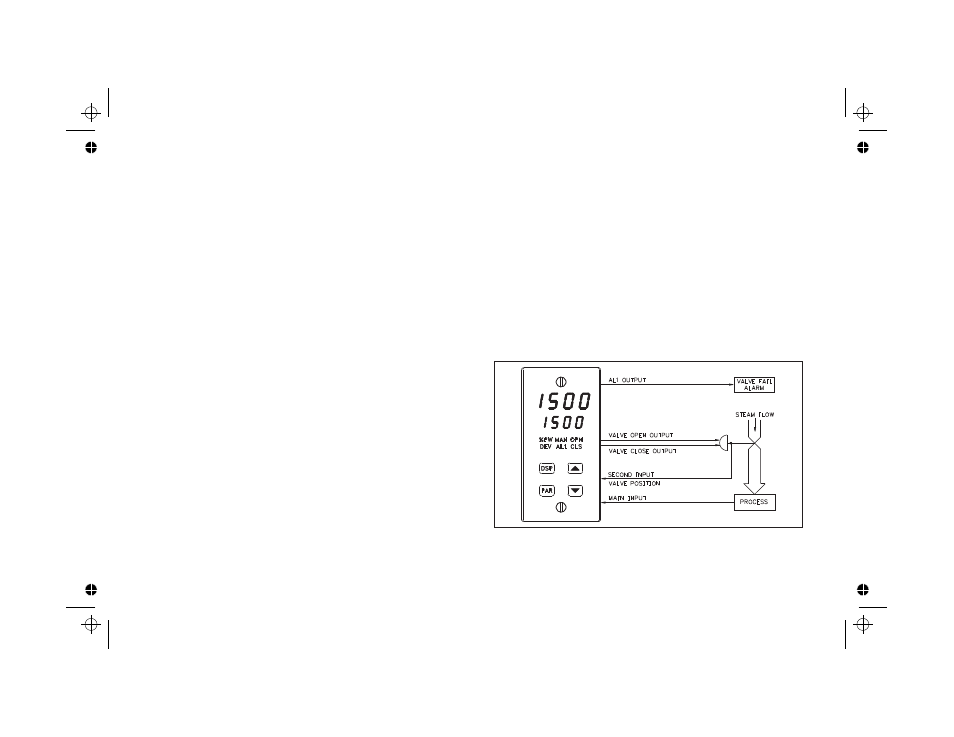

VALVE POSITION OPTION

The Valve Position option of the TCU directly controls the position of a

valve. The Valve Motor Open and Valve Motor Close outputs independently

activate the valve motor to position the valve for closed loop control. The

TCU is capable of two Valve Position control modes: Position mode, in

which valve position slidewire feedback is used by the controller, and

Velocity mode, a special positioning algorithm in which no slidewire signal

is required.

Position Mode Valve Control

In Position mode valve control, the slidewire resistance, representing the

valve position, is measured by the TCU and scaled internally to equal 0% to

100%. The scaled valve position is compared with the output power to

determine if the valve needs to be repositioned. Since the output power and

valve position both range from 0% to 100%, and normally equal each other,

the output power display (%PW) represents valve position. Based on this

information, the valve can be positioned manually from the Manual (USEr)

mode of the controller. The output power can be manually ranged from 0% to

100% to position the valve.

In the event that the valve position feedback and the output power do not

agree, due to a faulty valve motor, binding valve or defective slidewire, a

valve fail alarm occurs, if desired. The valve fail alarm is based on a timer in

which the output power and valve feedback positions must match within a

preset time. A display message of “VALV” occurs in this event. Optionally,

an alarm event output can be programmed to signal the event to other

equipment. Once the alarm triggers, the output power and feedback positions

must match to silence the alarm. Setting the valve fail time parameter to zero

disables this feature and also silences a triggered alarm.

The controller also senses loss of slidewire feedback signal and can

activate the

open

or

close

outputs in such an event. See

Sensor Fail Preset

Power (OPFL),

page 25, for a description of this operation.

Example

:

Steam is used to heat water by passing it through a heat exchanger.

Variations in inlet water temperature, steam pressure, hot water demand,

etc., all contribute to the need for closed loop control. The steam pressure is

controlled by a TCU with Valve Positioner option. A valve positioner with

1,000 ohm slidewire feedback is used. The TCU maintains constant hot

water temperature by controlling the position of the valve. Given the time

constant of the process is 60 seconds, the Valve Update Time (VUdt) of the

controller is set at five seconds to reduce valve activity. Adding Valve

Update Time to the valve motor transit time (20 seconds), the valve fail

time is set at 50 seconds [2 * (20+5)] to alert for a valve fail condition. The

valve position hysteresis is set at 2.0% to allow for valve motor overrun

and backlash, and also to provide a control deadband to reduce valve

activity. A minimum valve position is set to 20% to allow a minimum

amount of steam flow into the heat exchanger. The maximum valve

position is set at 100%. The following data is used to configure the Position

mode valve control parameters of the TCU:

VPS1

20.0

Scale minimum valve position to 20.0%

VPS2

100.0

Scale maximum valve position to 100.0%

Vudt

5

Update valve position, at most, once every 5

seconds

VPdb

2.0

Set valve position deadband to 2.0%

VFAL

50

Set valve fail timer to 50 seconds

58

Figure 28, Motorized Valve Positioner