Output status 49 – Red Lion TCU User Manual

Page 57

Sending Commands And Data (Cont’d)

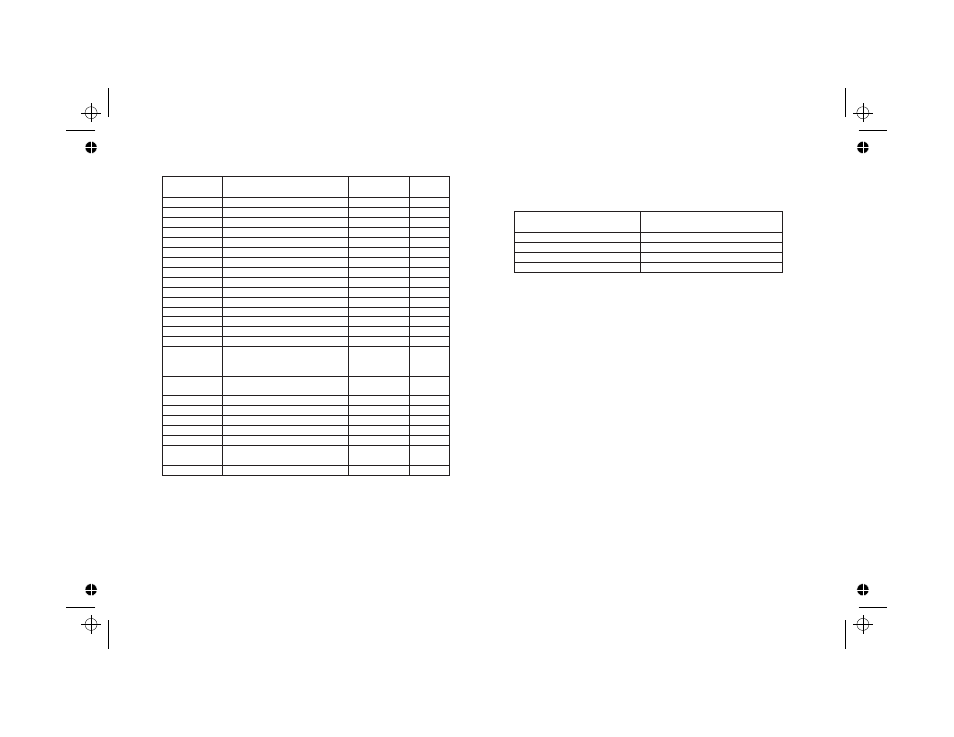

VALUE

IDENTIFIER

DESCRIPTION

SERIAL

MNEMONIC

UNITS

A

Temperature Display Value

TMP

F/C

B

Setpoint

SET

F/C

C

Output Power

PWR

%

D

Proportional Band

PBD

%

E

Integral Time

INT

S

F

Derivative Time

DER

S

G

Alarm 1

AL1

F/C

H

Alarm 2

AL2

F/C

I

Deviation

DEV

F/C

J

Output Power Offset

OFP

%

K

Setpoint Ramp Rate

RMP

R

L

Cooling Relative Gain

CRG

G

M

Cooling Deadband

CDB

F/C

O

Remote Setpoint Ratio

RAT

R

Q

Remote Setpoint Bias

BIA

U

S

Controller Mode

1 - Automatic

2 - Manual

(User)

U

Setpoint Mode

1 - Local

2 - Remote

W

Output status*

OST

U

X

Secondary Proportional Band

PB2

%

Y

Secondary Integral Time

IT2

S

Z

Secondary Derivative Time

DT2

S

AA

Second Input Reading

IN2

U

BB

Remote Setpoint Reading or

Secondary Directed Setpoint

RSP or

SP2

U

HC

Heater Current Reading**

HCR

A

Output status transmission format = ABCD (0=output off, 1=output on)

**

Interrogation of heater current value before the controller has taken a

valid heater current reading results in overload value (###.##). The heater

current reading printout is the last valid reading taken.

Note: The % output power can be changed only if the controller is in the

manual mode of operation.

*

The output status indicates the status of the controller’s outputs. The status

can only be read (see the following table). The alarms outputs may be reset

by the reset operator(R).

Output Status

NON-VALVE POSITIONER

MODELS

VALVE POSITIONER MODELS

A

=

Main output (OP1)

A

=

Alarm 1 output (AL1)

B

=

Cooling output (OP2)

B

=

0

C

=

Alarm 2 output (AL2)

C

=

Motor close output (CLS)

D

=

Alarm 1 output (AL1)

D

=

Motor open output (OPN)

Example

:

OP1 = ON, OP2 = OFF, AL2 = OFF, AL1 = ON

Transmission = “ OST 1001”

Note: The % output power can be changed only if the controller is in the

manual mode of operation.

The command string is constructed by using a command, a value

identifier, and a data value if required. The Data value need not contain the

decimal point since it is fixed within the unit, when programmed at the

front panel. The TCU accepts the decimal point, however it does not

interpret them in any way. Leading zeros can be eliminated, but all trailing

zeros must be present.

Example

: If an alarm value of 750.0 is to be sent, the data value can be

transmitted as 750.0 or 7500. If a 750 is transmitted, the alarm value

changes to 75.0 in the unit.

The address command allows a transmission string to be directed to a

specific unit on the serial communications line. When the unit address is

z e ro , t ra n s mi s s i o n o f t h e a d d re s s c o mma n d i s n o t re q u i re d . F o r

applications that require several units, it is recommended that each unit on

the line be assigned a specific address.

If they are assigned the same address, a Transmit Value Command causes

all the units to respond simultaneously, resulting in a communication

collision. The command string is constructed in a specific logical

sequence. The TCU does not accept command strings that do not follow

this sequence. Only one operation can be performed per command string.

49