Red Lion GEMINI 33 User Manual

Page 18

PROGRAMMING EXAMPLE

This example depicts a typical application for the Gemini 3300. The

programming steps and set-up will be discussed to give the user an

understanding on how to configure the Gemini 3300.

A typical industrial application for the Gemini 3300 will require a slow down

output, a final stop output, and an end of batch output. The Gemini 3300 can be

easily programmed to solve this requirement. Let’s look at a textile web process

that requires two outputs as the web progresses to the proper length and an output

when the desired number of rolls has been processed. A typical length of material

for this application is 1,000 feet. A slow down output is needed approximately

100 feet prior to the end of the 1000 foot length. After 100 rolls of material have

been processed, the power to the motor drive will be removed to prevent further

processing until the unit is reset. A light will also be turned on to indicate to the

operator that the run has been completed.

There are a couple of ways to set-up the Process Counter of the Gemini 3300.

The Process Counter could be set-up for “Manual Reset to Preset 2” operation.

Preset 2 would be set to the total length of 1000 and Preset 1 would be set to 100

(the distance before final cut where the slow down output is to occur). If the

total length were to change, only Preset 2 would need to be changed. Preset 1

would remain set to 100. If the Process Counter is set up for “Reset to Zero”

operation, Preset 2 would still be set to 1000, however Preset 1 would need to

be set to 900 (1000-100), so that the slow down output would still occur 100

feet before final cut. Normally in up-counting modes this type of application

would require that Preset 1 be changed along with Preset 2 every time a

different length was to be processed. With the Gemini 3300, this is not

necessary. The Gemini 3300 has a “Preset tracking” feature which causes

Preset 1 to track Preset 2 whenever the Preset 2 value is changed. In this

application we choose to utilize the second method of setting up the Process

Counter, using “Reset to Zero” operation with “Preset Tracking”.

The Batch Counter can also be set-up for “Reset to Zero” or “Reset to

Preset” operation.

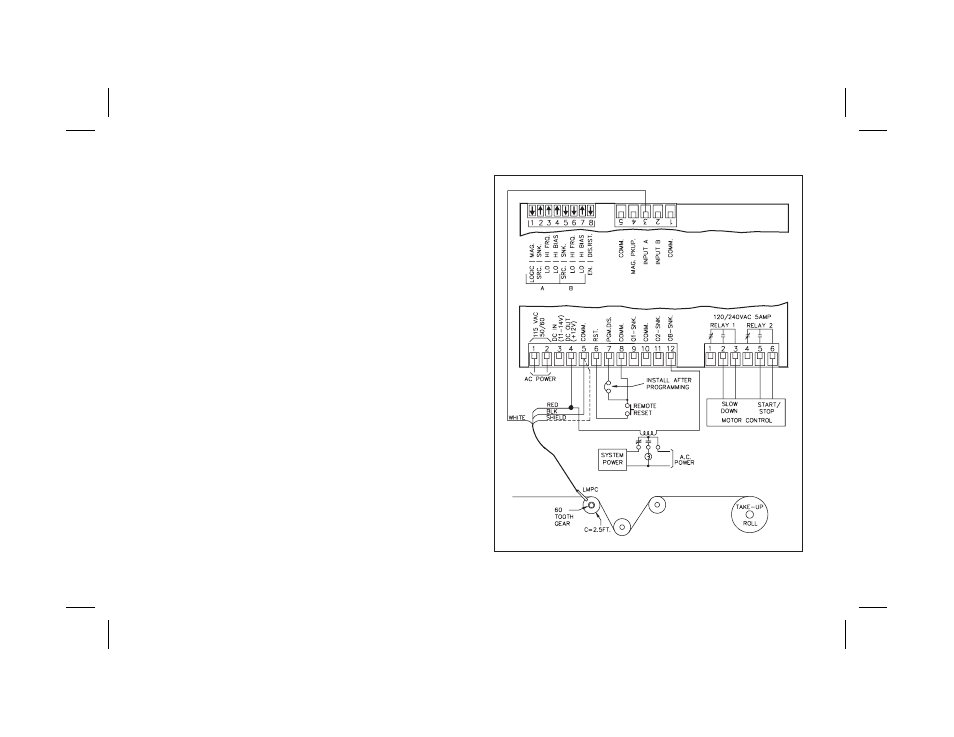

The accompanying drawing shows an LMPC sensing a 60 tooth gear which

is attached to a 2.5 ft. circumference drum. The desired units of display will be

feet. Since there is more than one pulse per foot of travel, the pulses input to

the Gemini will need to be scaled.

-16-