KROHNE TIDALFLUX IFM 4110 PF EN User Manual

Page 56

7.30830.32.00

56

7.6

Checking the primary head

Since the primary head consists of two “separated” parts (velocity measurement and level measurement), the

checking is separated in two parts.

If you encounter problems with the level meter, see section 7.6.1, in case of problems with the velocity

measurement see section 7.6.2..

7.6.1

Checking the level meter

•

Most faults concerning the level meter of the flowmeter can be eliminated by following the instructions in the following

tables.

Note: please make sure that the level indication is turned on in Fct. 1.04 as described in sect. 5.4.

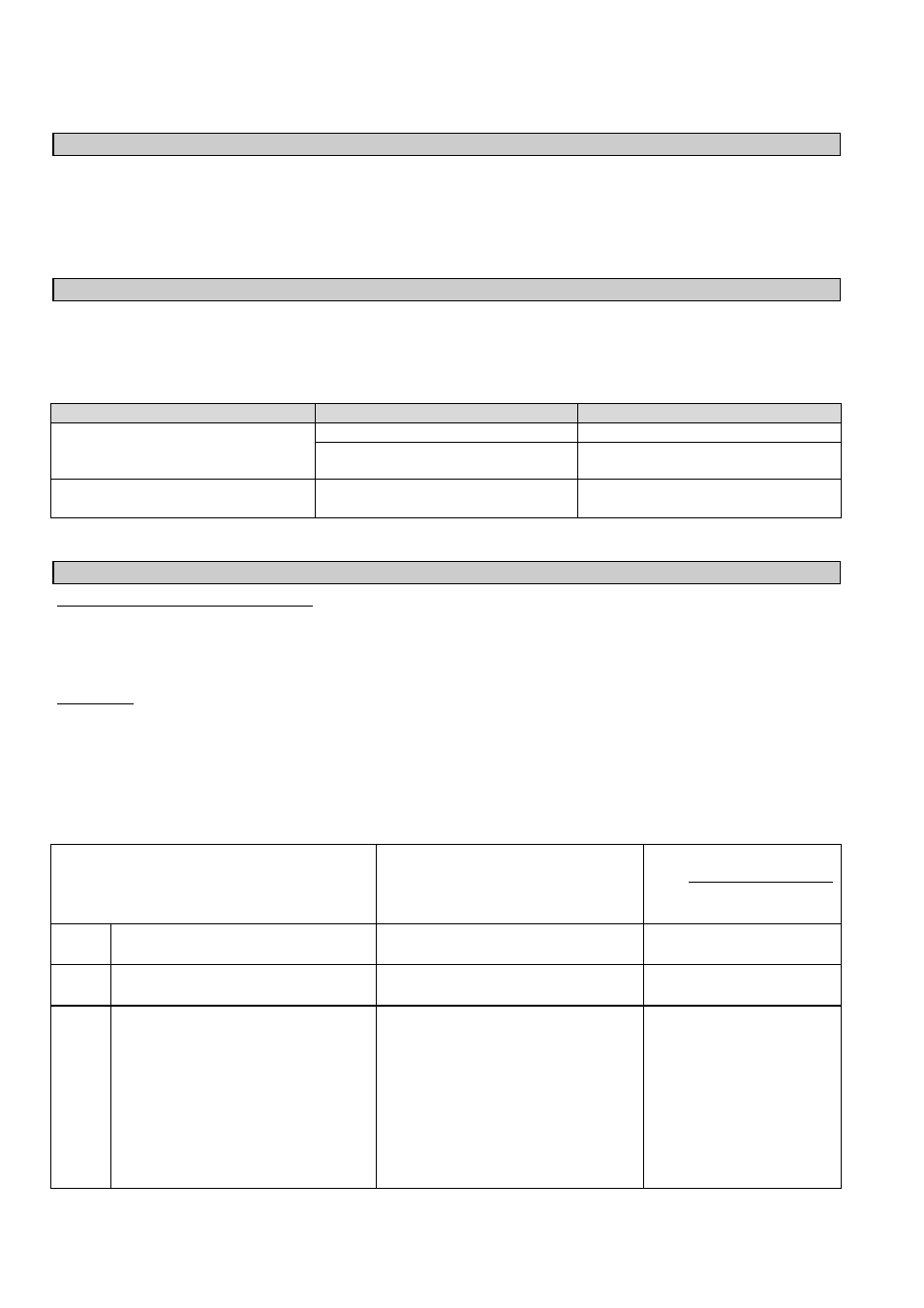

Faults / symptoms

Cause

Remedial action

inner side of tube heavily contaminated

clean inner side of tube

level too high

cable connections incorrect

check all cable connections acc. to

connection diagram in sect. 1.5.6.

level indicated is zero; red LED of IFC

110 PF flashes; indicated flow too high

no communication between

IFS 4000 PF and IFC 110 PF.

check all cable connections acc. to sect.

1.5.6.

7.6.2

Checking the velocity meter

Required measuring instruments and tools

•

Ohmmeter with at least 6 V measuring voltage range

•

or AC voltage/resistance bridge

•

Note:

accurate measurements in the electrode area can only be obtained with an AC voltage/resistance bridge.

The measured resistance also heavily depends on the electrical conductivity of the process liquid.

Preparations

•

Switch off the power supply of the IFC 110 PF.

•

Remove the cover from the terminal compartment (remove 2 screws).

•

Pull out the two plug-in terminals SC (5-pin, signal line) and FP (4-pin, field current supply line), see illustration in sect.

8.1.

•

Fill the measuring tube of the flowmeter completely with process liquid.

•

Please note: The following measurements must only be carried out for plug-in terminals which are occupied (used).

Action

Resistance measurements at plug-in terminals SC

(5-pin, signal line) and FP (4-pin, field current

supply line)

Typical result

Incorrect result for

1-3 = defective primary head,

return to factory for repair,

refer to last-but-one page!

1

Measure resistance between wires 7

and 8.

30 – 170

Ω

- If lower: interwinding fault

- If higher: wire break.

2

Measure resistance between wires 1

and 7 or between wires 1 and 8.

> 20 M

Ω

If lower: interwinding fault to

PE or FE.

3

Measure resistance between wires 1

and 2 and between 1 and 3 (same

measuring conductor always on wire 1 !)

1 k

Ω

- 1 M

Ω

(see “Note” above)

Both values should be approx. equal

- If lower: drain measuring

tube and repeat

measurement; if still too low,

short-circuit in electrode

wires.

- If higher: break in electrode

wires or electrodes

contaminated.

- If values differ considerably:

break in electrode wires or