Operation, Weld sequence, Start options – Lincoln Electric IM946 CRUISER Digital Tractor User Manual

Page 88

Cruiser™ Tractor

OPERATION

10-11

10-11

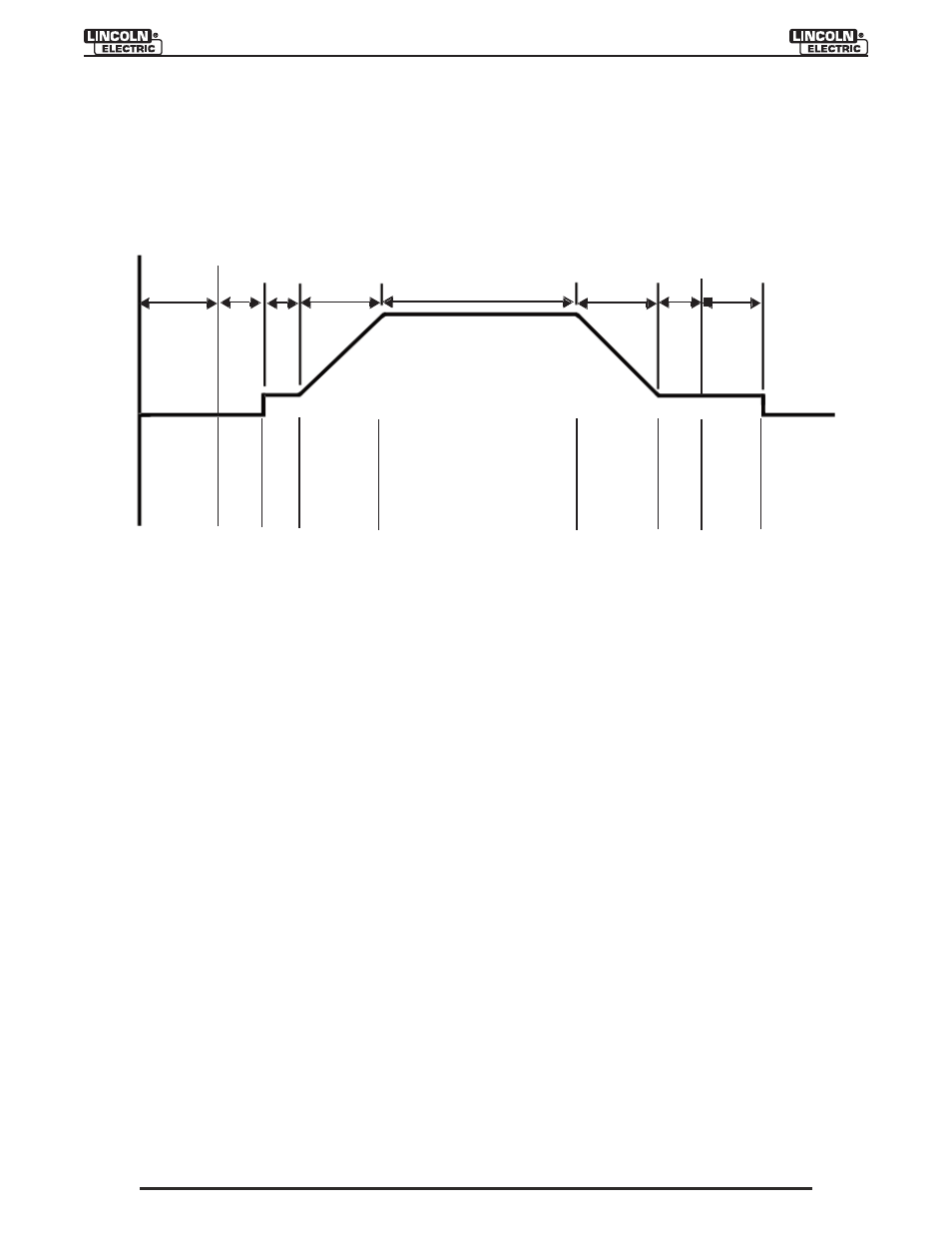

Arc Start

Delay

Downslope Crater

Start

Burnba

ck

Upslope

Weld

Strike

Output

Start Button

Pressed

Wire Begins

to Feed

Wire T

ouches

Plate

End of

Upslope

End of

Downslope

End of Crater

T

imer

Stop Button

Pressed

Time

Weld Sequence

The weld sequence defines the weld procedure from beginning to end. All adjustments

are made through the user interface.

Figure 10-5 Weld Sequence

Start Options

The strike, start and upslope parameters are used at the beginning of the weld se-

quence to establish a stable arc and provide a smooth transition to the welding parame-

ters. They are described in the following:

• Strike settings are valid from the beginning of the sequence (trigger) until the arc is

established. They control run-in (speed at which the wire approaches the work-

piece) and provide the power to establish the arc. Typically output levels are in-

creased, and WFS is reduced during the strike portion of the weld sequence.

• Start values allow the arc to become stabilized once it is established. Extended start

times or improperly set parameters can result in poor starting.

• Upslope determines the amount of time it takes to ramp from the start parameters to

the weld parameters. The transition is linear and may be up or down depending on

the relationship between the start and weld settings.

End of

Burnback

End of Start

T

imer