Operation b-3, Welding procedures – Lincoln Electric IMt913 MAGNUM 100SG SPOOL GUN User Manual

Page 25

OPERATION

B-3

After choosing the proper welding wire

for your application, load the aluminum

wire, connect the gun and cable to the

welding machine. (See Installation

Section).

WELDING PROCEDURES

1. Read and understand Arc Welding Safety

Precautions located throughout this manual

and the Welding Machineʼs Instruction Manual.

Also for helpful hints in welding see (LTW1) the

Learn to Weld manual which is supplied with

the welding machine.

2. Obtain and use the proper personal protective

equipment for welding. Connect the WORK

(welding ground) cable(-) to piece(s) being

welded. Make sure gas hose from cylinderʼs

regulator is connected to welderʼs gas INLET.

Open cylinderʼs gas valve.

3. Connect input power to the machine.

4. Turn the machineʼs power switch to "on". Set

wire speed and voltage tap settings to tables

which are provided in the beginning of this

section.

5. Flip toggle selector switch inside of machine to

"Magnum® 100SG" position. Press and hold

trigger for about 5 seconds to purge hose. Be

sure the Gas flow rate is set to 20 to 50 SCFH

thru the spool gun.

6. Cut off the aluminum wire so that it extends

about 1/4 inches from the contact tip.

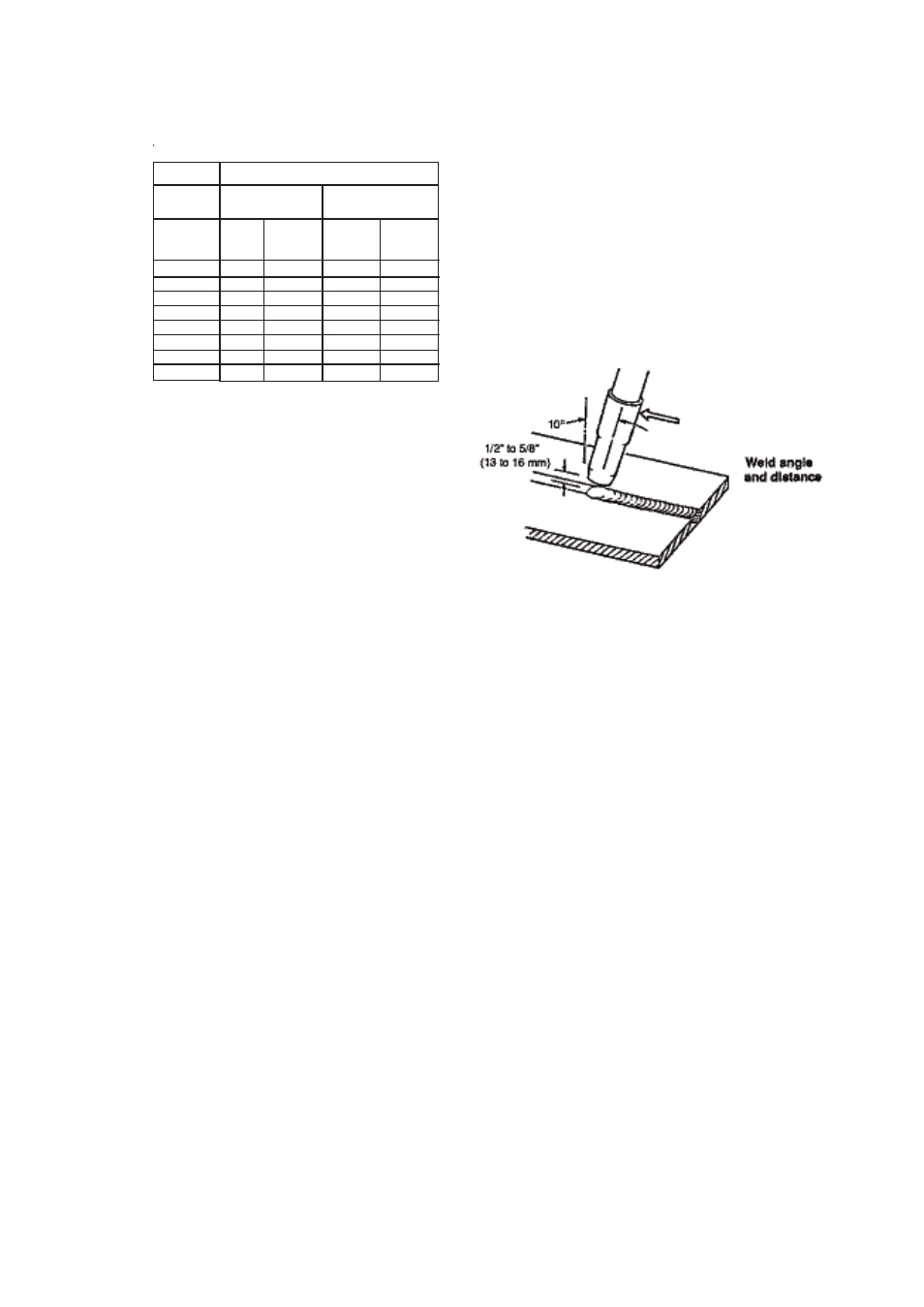

7. CTWD (Contact Tip to Work Distance): Position

the gun so that the contact tip is nominally 3/8

inches from the joint and tilted with a push

angle toward it. The aluminum wire should not

contact the workpiece. (See figure B.1)

FIGURE B.1

8. Protect the eyes and pull the trigger to begin

welding.

9. Adjust the hand travel speed of the gun to

achieve a proper weld. The emerging wire

should stay within the molten puddle and not

overrun it. This speed also should not be so

slow that either the workpiece excessively

melts, or the weld bead becomes excessively

large.

10. Release the trigger to stop welding.

Alloy:

Wire Size:

Weldment

Thickness

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3/16 in.

Speed

2.5

2.5

4.5

5

6

7

N/A

N/A

Voltage

Tap

A

B

C

D

E

E

N/A

N/A

Speed

2

2

4

4.5

5

5.5

N/A

N/A

Voltage

Tap

A

B

C

D

E

E

N/A

N/A

0.030

0.035

5356

Weld-Pak 125 MACHINE

Alloy:

Wire Size:

Weldment

Thickness

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3/16 in.

Speed

2.5

2.5

4.5

5

6

7

N/A

N/A

Voltage

Tap

A

B

C

D

E

E

N/A

N/A

Speed

2

2

4

4.5

5

5.5

N/A

N/A

Voltage

Tap

A

B

C

D

E

E

N/A

N/A

0.030

0.035

5356

Weld-Pak 125 MACHINE