Installation – GF Signet 9900-1BC Batch Controller System User Manual

Page 3

3

9900-1BC Batch Controller Manual

Panel Mount Installation

Tools and Equipment Required

• Fine-tooth fi le

• ¼ DIN punch or jigsaw suitable for cutting panel opening to within

1 mm (0.04 in) tolerance.

• ¼ DIN punches are available and recommended for creating clean, precise

openings quickly and easily in most instrument panels.

• If a punch is not available, a jigsaw or other cutting tool can be used.

An adhesive template is provided to help guide the cutting process.

De-burr and smooth the opening with a fi le.

Installation

Do not mount in direct sunlight.

Recommended clearance on all sides between instruments is 25 mm (1 in).

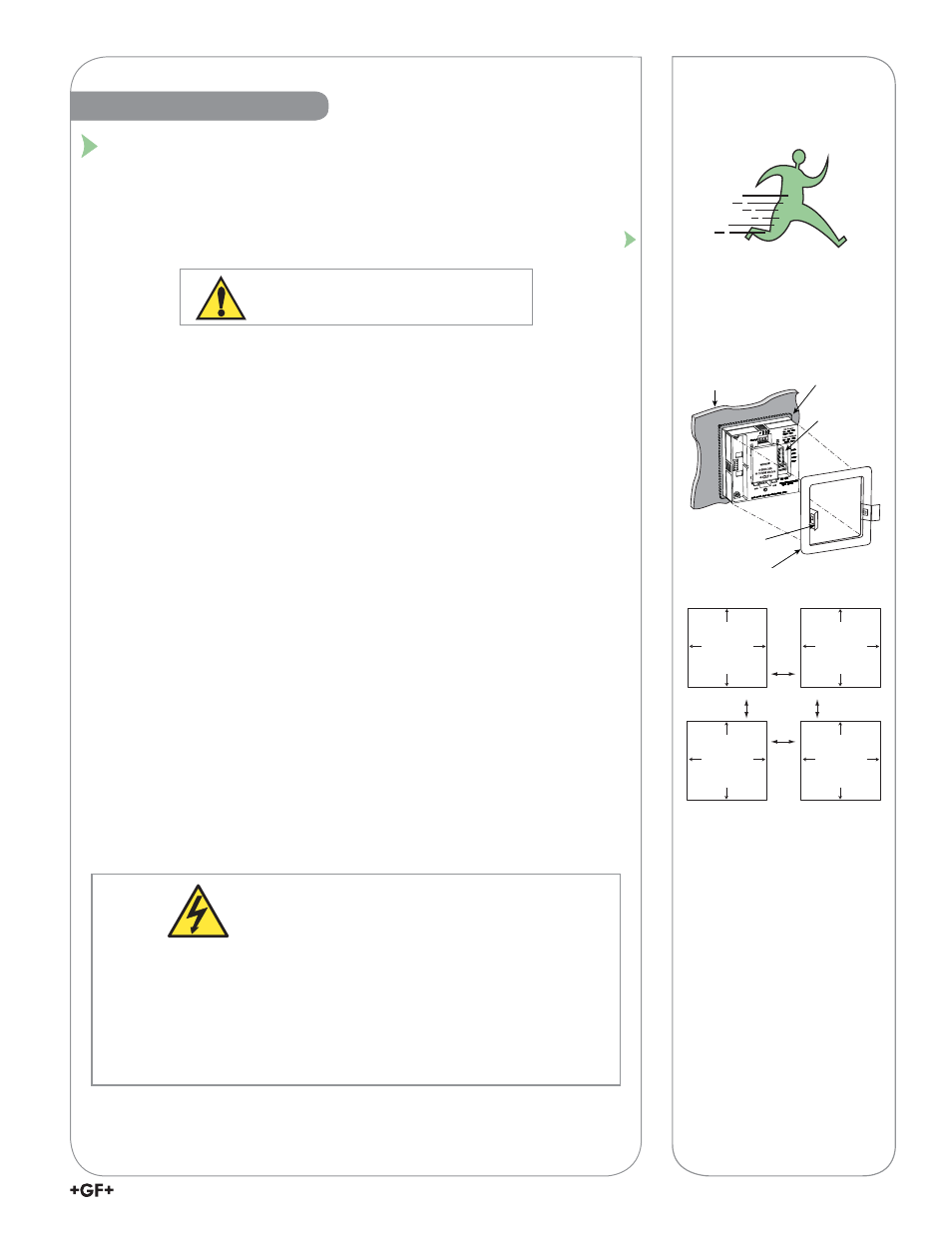

1. Place gasket on instrument, and install through ¼ DIN size opening.

2. Slide mounting bracket over back of instrument until bracket snaps into

latches on sides of instrument.

To remove:

1. Secure instrument temporarily with tape from front or grip from rear of

instrument. DO NOT RELEASE.

2. Press bracket clips outward and remove.

Field Mounting

The Panel Mount unit can be installed in the optional Wall Mount Accessory

(3-9900.392, 159 001 700), for fi eld mount installation.

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

minimum

clearance

25 mm

(1 in.)

panel

Quick-clip

gasket on

front side

of panel

plugs

mounting

DC Power

Loop V

oltage

3-9900.395

H COMM Module

System Start-up: Step 1

Prepare the Controller installation location. If the back of the Controller is

diffi cult to access when installed, wire the removable terminal plugs fi rst,

then attach to 9900 Transmitter.

Next step: Wiring (Step 2).

• Minimize handling of plug-in modules to reduce the possibility of

damage due to ESD.

• Handle modules by the edges. Never touch any exposed circuitry or

contacts.

• Wear an anti-static wristband or stand on an anti-static mat, or

keep one hand touching a properly grounded pipe or other properly

grounded piece of metal when handling modules.

CAUTION:

Avoid Electrostatic Discharge (ESD)