Burkert Type 2100 User Manual

Page 30

30

Maintenance, cleaning

Series production status up to January 2013

→

Unscrew the spindle guide with the aid of the installation

wrench

7)

and an open-end wrench.

Series production status since January

→

Unscrew the spindle guide with the aid of a modified socket

wrench

7)

.

WARNING!

Risk of injury from parts jumping out!

When the spindle opening is exposed, the individual parts of the

packing gland are pressed out at an undefined speed when the

pilot air ports is pressurized.

• Before pressurizing with control air, safeguard the ambient area

of the discharge opening (e.g. place spindle on a firm base).

→

Control function A and I Pressurize pilot air port 1 with 6 – 8

bar (see “Fig. 22: Designation parts”).

→

Control function B Pressurize pilot air port 2 with 6 – 8 bar (see

“Fig. 22: Designation parts”).

→

Grease the individual parts of the new packing gland with the

upplied lubricant.

→

Connect the individual parts to the spindle in the specified

direction and sequence (as illustrated in “Fig. 26”).

7)

The installation wrench or modified socket wrench is available

from your Bürkert sales office.

→

Push packing gland into the packing gland tube.

→

Screw spindle guide back in using the installation tool. Observe

torque (see “Tab. 7”)

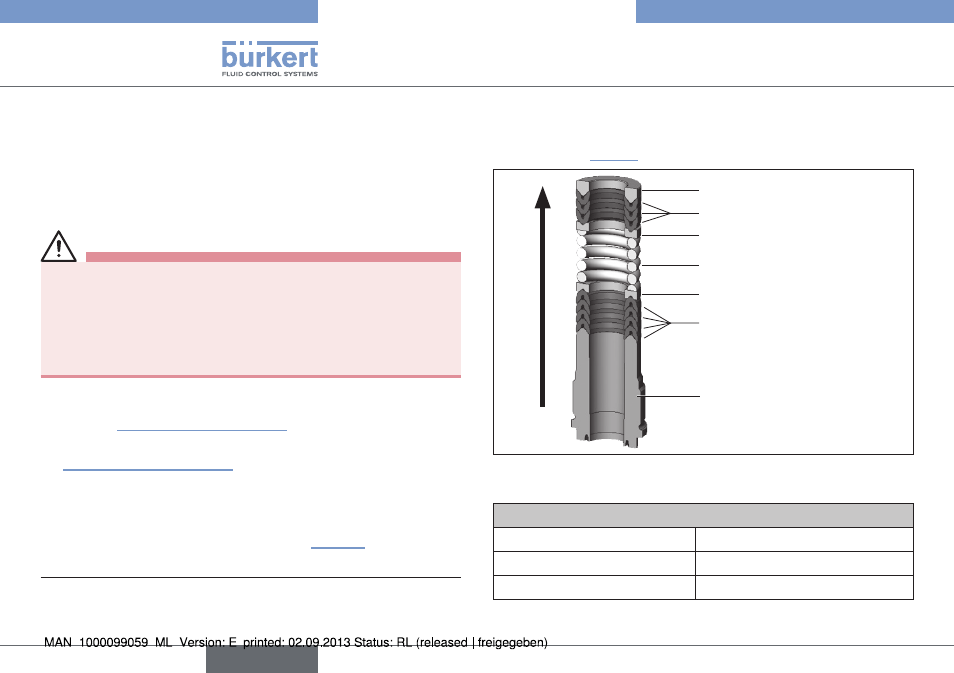

Support ring

Upper chevron seals

Upper pressure ring

Pressure spring

Lower pressure ring

Lower chevron seals

Spindle guide

Insertion direction

for packing gland parts

Fig. 26: Seal set for packing gland

Tightening torques of spindle

Spindle diameter

Tightening torque [Nm]

10 mm

6

14 mm

15

Tab. 7: Tightening torques of spindle

english

Type 2100