Maintenance work – Burkert Type 2100 User Manual

Page 24

24

Maintenance, cleaning

WARNING!

For control function I – Danger if pilot pressure fails!

For control function I control and resetting occur pneumatically.

If the pressure fails, no defined position is reached.

• To ensure a controlled restart, first pressurize the device with

pilot pressure, then switch on the medium.

11.2. Maintenance work

Actuator:

The actuator of the angle seat valve is maintenance-free provided it

is used according to these operating instructions.

Wearing parts of the angle seat valve:

Parts which are subject to natural wear:

• Seals

• Swivel plate

→

If leaks occur, replace the particular wearing part with an appro-

priate spare part. (For spare-part sets and installation tools see

chapter entitled “13. Replacement parts”).

The replacing of the wearing parts is described in chapter

“11.3. Replacing the wearing parts”.

Visual inspection:

Perform regular visual inspections according to the application

conditions:

→

Check media connections for leaks.

→

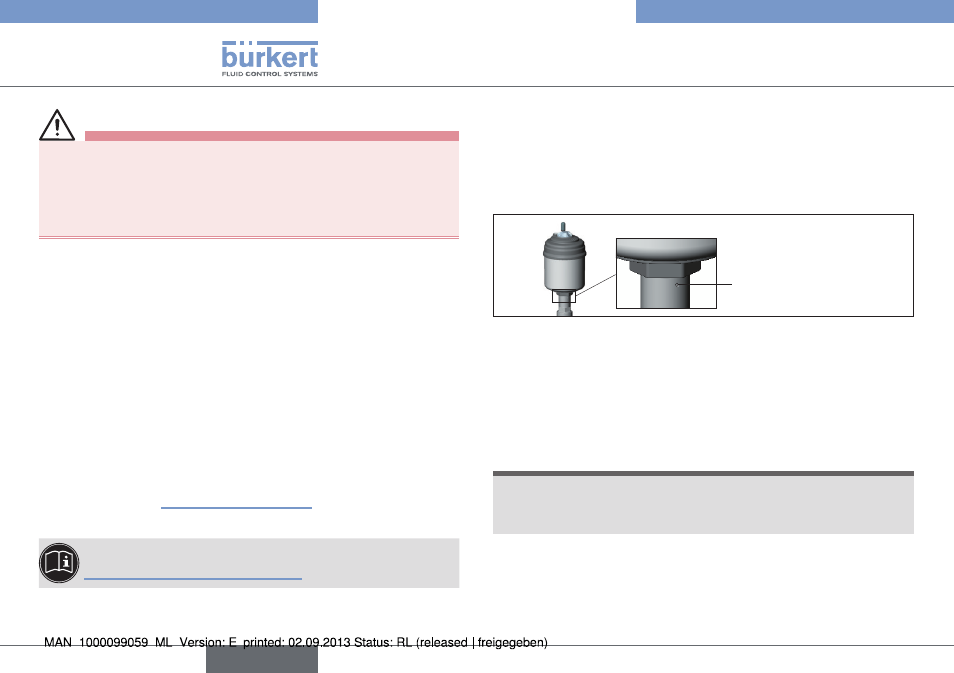

Check release bore on the tube for leaks.

Release bore

Fig. 18: Release bore

11.2.1. Cleaning

Commercially available cleaning agents can be used to clean the

outside.

NOTE!

Avoid causing damage with cleaning agents.

• Before cleaning, check that the cleaning agents are compatible

with the body materials and seals.

english

Type 2100