Franklin Fueling Systems TS 550 evo Fuel Management System Operators Guide User Manual

Page 9

5

Optional Modules

2-Wire Sensor Module

Provides 12 inputs for 2-wire

Standard sensors.

3-Wire Sensor Module

Provides 8 inputs and

supports both 3-wire and

2-wire sensors.

4-20 mA Input Module

Provides 8 inputs that can be

used for TS-LS500 line leak

detection transducers and

SCM vacuum transducers.

4-20 mA EXP

Explosion-proof module.

Otherwise the same as the

4-20 mA Input Module.

AC Input Module

Provides 12 inputs for

dispenser hook signals, which

are also required for LLD. This

module replaces external DHI

boxes.

Probe Module

Provides 12 inputs or LL2

probes.

Relay Module

Provides 8 relay outputs (2-

Amp) which are typically used

to control the submersible

pump relays to provide pump

or dispenser shutdown when

line leak detection or other

applications are used. Not

used in combination with TPI.

10-Amp Relay Module

Provides 6 relay outputs which

are typically used to control

the submersible pump relays

to provide pump or dispenser

positive shutdown upon alarm

conditions.

Input / Output Module

Provides 8 AC or DC voltage

inputs that can range from 3

to 240 volts. Typically used for

vapor processors and generic

devices, but not for dispenser

hook signals. In addition, this

module also includes four

4-20 mA signal outputs which

are typically used to interface

to an external device, such

as a SCADA (Supervisory

Control and Data Acquisition),

building monitoring system or

fuel level monitoring.

User Interface

LED Indicators – Three LEDs below the front panel give

an “at-a-glance” indication of the system status. These

LEDs are standard on all systems. The green Power LED

indicates that the system power is on. The yellow Warning

LED gives indication that the console has detected a

malfunction or condition that has been deemed a Warning.

The red Alarm LED indicates that the system has detected

an alarm condition.

LCD Touch Screen – The color LCD touch screen is

the most commonly used user interface for the Fuel

Management System. This bright and colorful display

allows easy viewing in any lighting condition. Touching

certain buttons or segments of the screen will allow access

to menus or more detailed information.

Do not use sharp

or pointed objects to operate the touch screen or damage

may result. A “Sleep Mode” screensaver can be activated

under Setup / Configuration / Sleep mode to automatically

turn off the back light after 5 minutes to extend the life of

the display. If improper operation of the touch screen is

noted, it may be necessary to calibrate the touch screen.

Please refer to the Routine Maintenance chapter of this

manual for calibration procedures.

Alarms and Warnings

Alarms and warnings are designed to alert you with

specific details when a problem occurs so that you can

take appropriate corrective action. System hardware

failure warnings, tank related alarms, leak detection sensor

alarms, and line leak alarms will always notify the user in

certain ways, other notification options are programmable.

Alarms and Warnings will always:

• Cause the red Alarm light or yellow Warning light to

flash (standard).

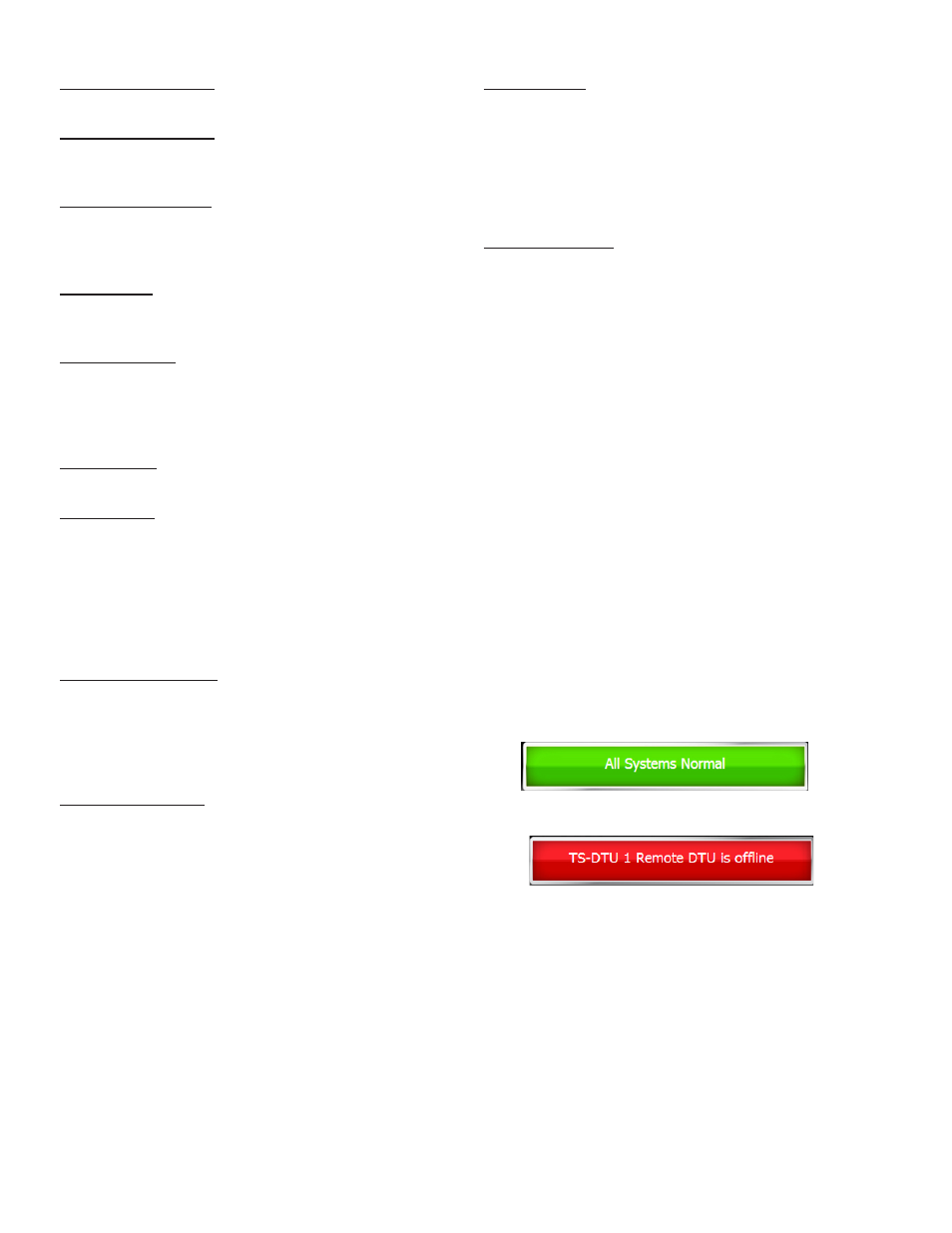

• Change the alarm button from showing normal:

to showing the alarm. i.e.:

.

Optionally, on alarm the system can:

• Sound the console’s internal alarm horn.

• Activate relay outputs and sound external alarm

devices.

• Print alarm reports.

• E-mail alarm reports to a specified destination.

• Notify remote monitoring software via optional

internal modem or Ethernet.

For help with troubleshooting alarms, refer to the

Troubleshooting chapter of the TS-550 evo Series

Programming Manual (000-2173).