Tank testing – Franklin Fueling Systems TS 550 evo Fuel Management System Operators Guide User Manual

Page 19

15

Tank Testing

There are two types of Tank Testing available in the Fuel

Management Systems: Static and SCALD.

Static tests are run during quiet times when the tank is

thermally stable and the site is closed so that no dispensing

or deliveries will occur. There are two types of Static tests:

Monthly (0.2 gph) and Annual (0.1 gph). Static tests can

be scheduled to run on a Daily, Weekly or Monthly basis in

the Setup menu (Administrator use only). They can also be

started on demand from the

tank detail screen. Make sure

that all testing conditions are met before starting a Static

Tank Test.

SCALD (Statistical Continuous Automatic Leak Detection)

tests run 24 hours a day and look for periods of quiet time

when the tank is thermally stable and no dispensing or

deliveries are occurring. These quiet periods are collected

and analyzed and the tightness of the tank is determined.

SCALD tests will update whenever possible and can

be setup to print automatically when they do. The more

common method is to schedule the latest SCALD test to

print out once a week, saving a significant amount of paper

because SCALD tests can be generated multiple times a

day on a quiet tank.

Static and SCALD tests run independently of each other

and can be run at the same time. A SCALD test will likely

complete during the time that the Static test is running.

All Franklin Fueling Systems Fuel Management Systems

meet the requirements of the U.S. Environmental

Protection Agency (EPA/530/UST-90/006 test protocol) for

Automatic Tank Gauging Systems (ATGS). The system(s)

also meet the requirements for Annual Tank Tightness

Testing for 0.1 gal/hr leaks of the National Work Group on

Leak Detection Evaluations (NWGLDE). Third Party Testing

Laboratory test results (for standard static tank leak tests)

are also available at

http://nwglde.org/

.

Why Test the Integrity of a Tank

In compliance with federal, state and local regulatory

policies, all tanks must be monitored for leaks due to

environmental and public safety/health concerns. Tank

tightness testing determines if there is a leak.

Static Testing

Terms

Threshold – Test results must be within these

programmable limits to pass a leak test. There are Monthly,

Annual and Sentinel Mode Thresholds.

Sentinel Mode – Sentinel mode is designed to monitor the

product levels in your tank(s) when there isn’t supposed to

be any dispensing.

Confidence – Level of testing

sensitivity indicating the probability

that the test will detect a leak. Higher

confidence percentages will produce

more sensitive test results. Check

local regulations to verify acceptable

confidence levels.

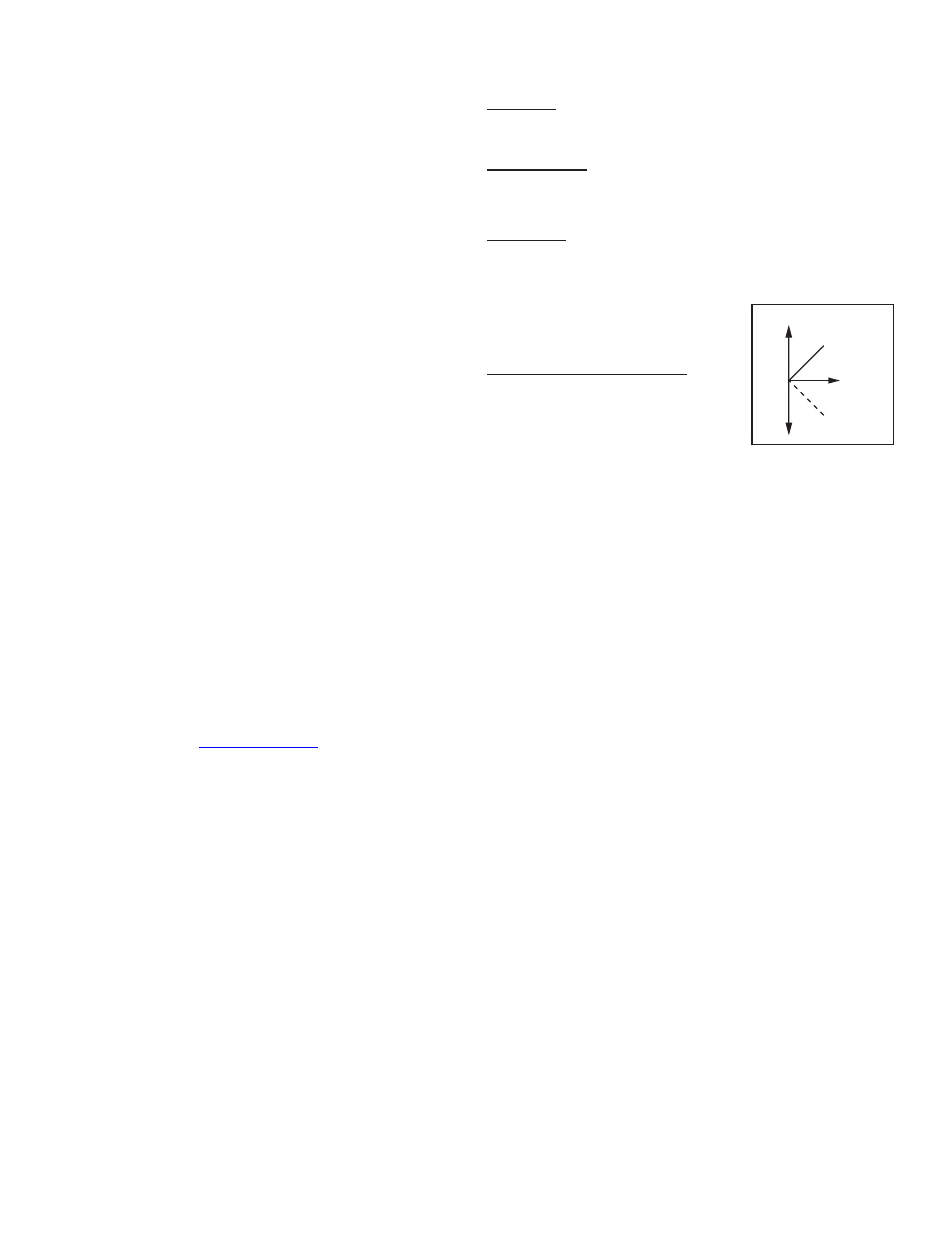

Flow

Time

No Leak

(+) slope

(–) slope

Slope (Tank Testing Reports) – A

ratio of the calculated rate of change

to the time the rate is measured.

Slope is affected by leaks and by

many other sources of interference.

A negative slope or decrease

indicates loss of product volume. A

positive slope or increase indicates a

rise in product volume.