Franklin Fueling Systems TS 550 evo Fuel Management System Operators Guide User Manual

Page 35

31

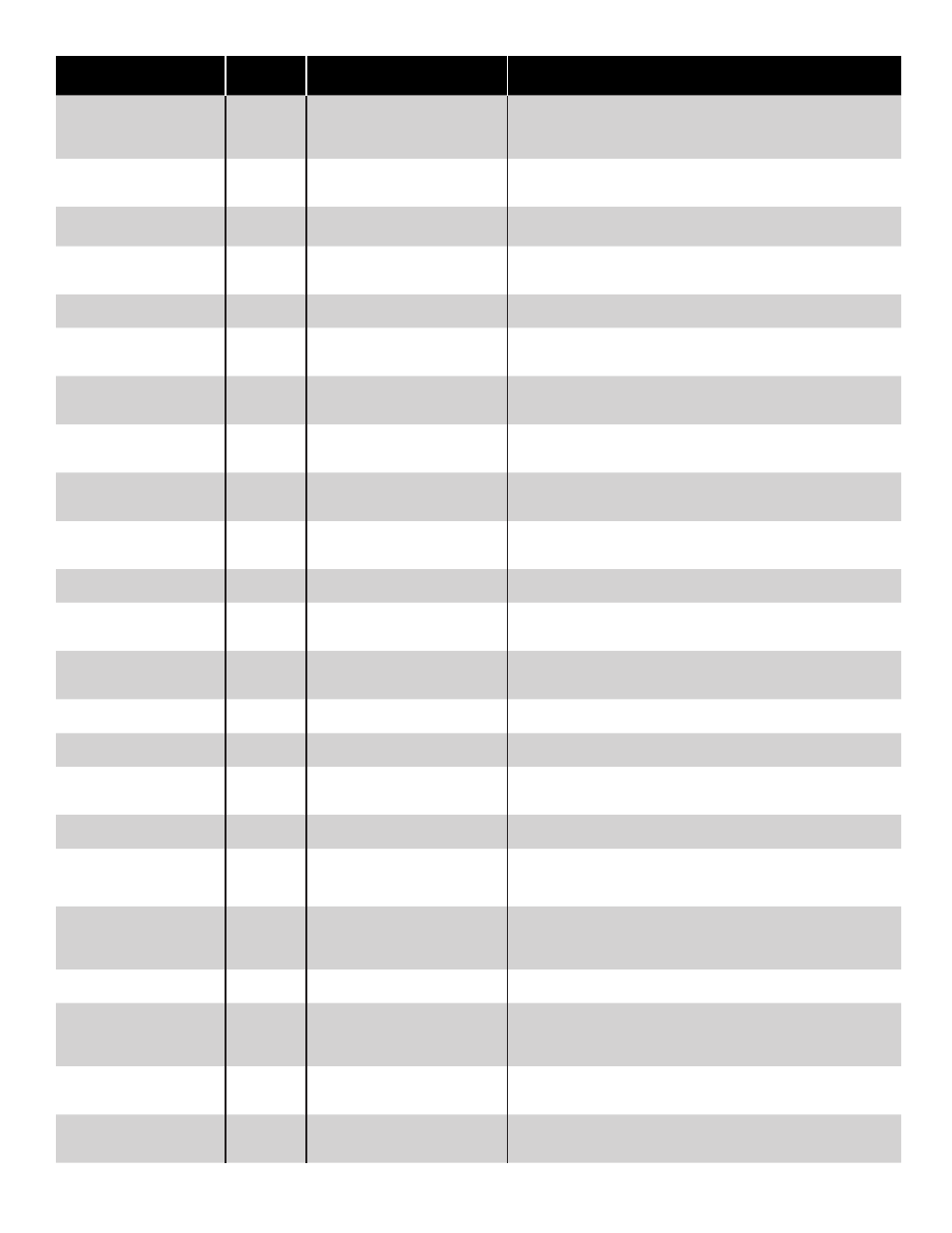

Displayed Alarm /

Warning

Device

Description

Recommended Actions

Manifold Theft Detected

Tank

The specified manifold has entered

Sentinel Mode and detects product

leaving the tank that exceeds the

programmed theft limits.

Verify programming and accurate level / volume readings.

Modem Error

None

Indicates that a modem

malfunction has occurred.

Try to recycle power on the console. Verify modem programming. If

the alarm does not clear, contact Franklin Fueling Systems’ Technical

Services Dept. for support on this issue.

Monthly Compliance

Alarm

Any

The device listed has gone

out of compliance

Pass a test or clear the alarm on the device.

Monthly Compliance

Warning

Any

The device listed has 7 days

before it will go into a compliance

alarm.

Pass a test or clear the alarm on the device.

Net error

Tank

Product net levels exceed tank

diameter

Verify tank, product offset and probe programming

No data available

System

A communication issue has

occurred between the probe and

the console

Check for proper probe programming at the console and inspect

wire connections at the probe. If the problem persists, contact FFS

Technical Services for support.

No probe detected

Tank

The Console is not receiving any

communication from the probe.

Check for proper probe programming at the console and inspect

wire connections at the probe. If the problem persists, contact FFS

Technical Services for support.

Probe synchronization

error

Tank

Communication between the

probe and the Console is either

incomplete or ill timed.

Check for proper probe programming at the console and inspect

wire connections at the probe. If the problem persists, contact FFS

Technical Services for support.

Product volume error

Tank

The Product Volume as reported

by the probe has exceeded the

limits of the tank.

Check for proper probe and tank programming at the console. If

programming is correct, inspect the probe to ensure that the float is

not stuck in the riser or is otherwise obstructed.

RTD table error

Tank

RTD distance error; Special Probe

programming error.

Verify correct RTD programming. If issue still exists, inspect wiring to

probe.If the condition still exists, contact Franklin Fueling Systems’

Technical Services for support.

System memory error

System

The system has detected a low

memory situation.

Contact FFS Technical Services for support.

Tank Gross Leak Detected

Tank

Tank Gross leak test detected

tank. Suspect possible leak.

Review tank leak test history and programming.

Refer to Section 5: Misc. / Tank Leak Tests – Type and Frequency for

instructions on manually starting line leak tests.

Tank Leak Detected

Tank

Tank leak detected. Suspect

possible leak.

Review tank leak test history and programming.

Refer to Section 5: Misc. / Tank Leak Tests – Type and Frequency for

instructions on manually starting line leak tests.

Tank Product Density

High Limit Exceeded

Tank

The Product Density exceeds the

programmed high limit.

Verify programming if correct this alarm may be an indication of

improper density of the fuel.

Tank Product Density Low

Limit Exceeded

Tank

The Product Density has exceeded

the programmed low limit.

Verify programming if correct this alarm may be an indication of

improper density of the fuel.

Tank SCALD Leak

Detected

Tank

SCALD leak test detected tank

leak. Suspect possible leak.

Review Tank Leak Test History and programming.

Refer to Section 5: Misc. /Tank Leak Tests – Type and Frequency for

more information on SCALD tests.

Tank Delivery Detected

Tank

A delivery has been detected on

the specified tank.

This is not an alarm and should only be a concern if there was not a

delivery to the site at the specified date and time.

Tank Water/Phase Sep

Float Disabled

Tank

The Phase Separation Water Float

has been disabled in setup

Verify Phase Separation Water Float level and enable the float in

setup.

Tank Theft Detected

Tank

Product used in Sentinel Mode

exceeds theft limit set. Suspect

theft, and then verify theft limit in

programming.

Verify theft limit in programming. Also obtain an accurate product level

and compare to inventory.

Temperature error

Tank

Special Probe RTD temperature

error detected.

Verify correct RTD table programming. If problem still exists, suspect

wiring or faulty probe.

Ullage error

Tank

Ullage reported has exceeded

tank capacity.

Check for proper probe and tank programming at the console. If

programming is correct, inspect the probe to ensure that the float is not

stuck in the riser or obstructed. Bring the probe inside and wire directly

to the gauge to eliminate possible problems with the field wiring.

Unstable probe

Tank

LL Liquid Level probes can send

FFSsistent data back to console.

Check for proper probe programming at the console and inspect

wire connections at the probe. If the problem persists, contact FFS

Technical Services for support.

Water volume error

Tank

Water volume has exceeded tank

capacity.

Check for proper probe and tank programming at the console. If

programming is correct, inspect the probe to ensure that the colored

water float is on the bottom.