Fms alarms – Franklin Fueling Systems TS 550 evo Fuel Management System Operators Guide User Manual

Page 33

29

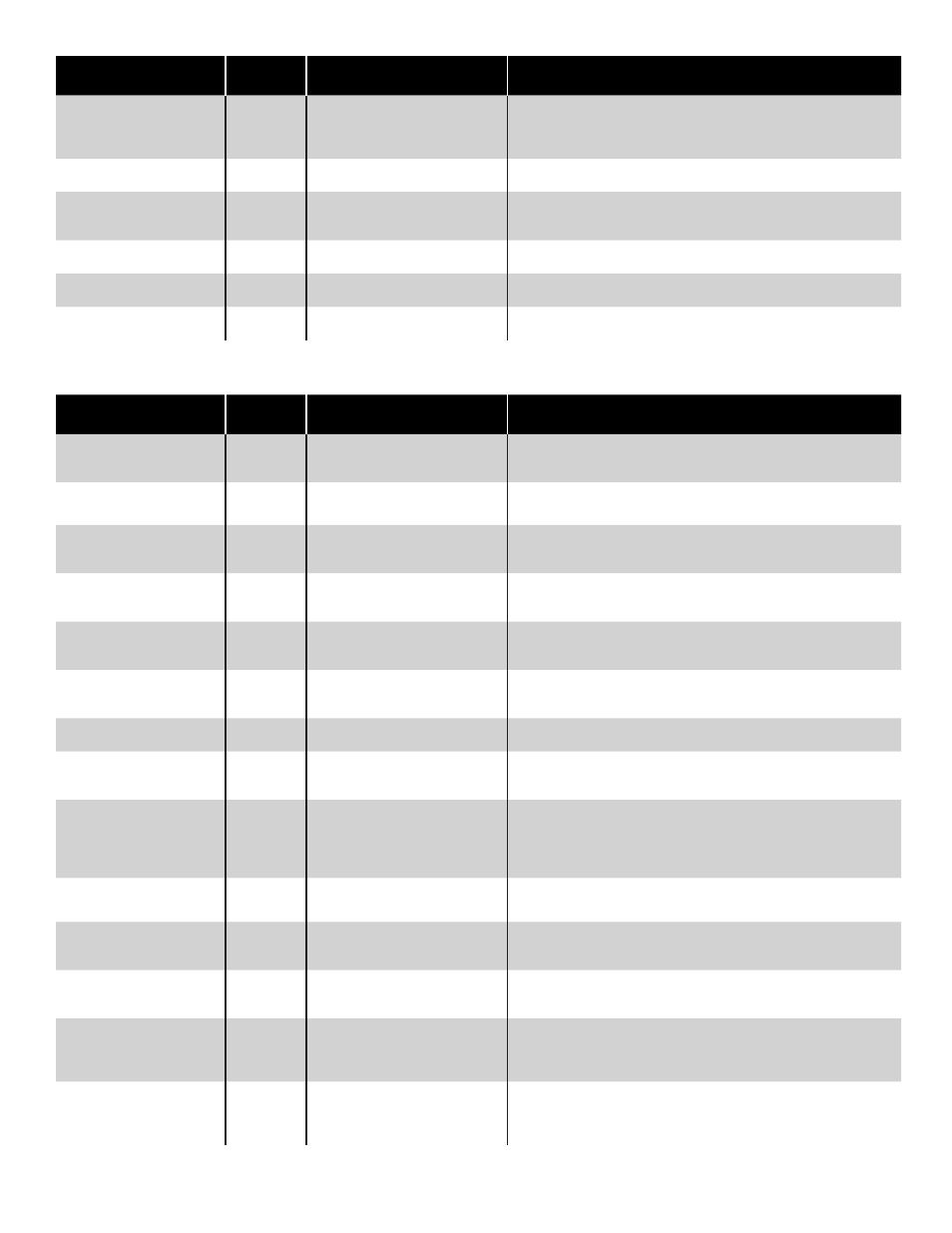

Displayed Alarm /

Warning

Device

Description

Recommended Actions

Relay module number

mismatch

slot

Relay Modules detected does not

match the number programmed.

Check that the number of Relay Modules installed matches the num-

ber programmed under System Configuration > Modules Expected.

Check for a flashing green light or no light at all on the AC Input

Module and contact FFS Technical Services for support.

Relay Module Setup Error

None

An error exists in the Relay

Module configuration

Inspect the Relay Module setup configuration for possible errors. Pay

particular attention to if the module is configured for 10amps or not.

Secondary Containment

Monitor Setup Error

None

An error exists in the configuration

of the Secondary Containment

Monitoring Setup.

Inspect the Secondary Containment Monitor setup configuration for

possible errors.

Set Date and Time

None

System detected an issue with the

date and time

Check and set the system date and time.

System bus error

Slot

Data transfer errors occurred in

the System Bus.

Upgrade to the latest version of firmware available at:

www.franklinfueling.com

System Setup Error

None

There is an error in the Setup

configuration.

Inspect the System setup configuration for possible errors.

FMS Alarms

Displayed Alarm /

Warning

Device

Description

Recommended Actions

Alpha volume correction

error

Tank

This error is caused by a

programming mistake in the

Special Products section.

Verify Special Product Alpha volume correction program parameters.

Contact FFS Technical Services Department for assistance.

Annual Compliance Alarm

Any

The device listed has gone out of

compliance

Pass a test or clear the alarm on the device.

Annual Compliance Warning Any

The device listed has 7 days

before it will go into a compliance

alarm

Pass a test or clear the alarm on the device.

API volume correction

error

Tank

This error is caused by a

programming mistake in the

Special Products section.

Verify Special Product API volume correction program parameters.

Contact FFS Technical Services Department for assistance.

Correction table error

Tank

Level and Volume mismatch

detected in Correction table

programming.

Verify that all levels and volumes are entered accurately into the

Correction Table programming.

Density float error

Tank

A communication error has

occurred involving the density

float.

Verify programming and contact FFS Technical Services for support.

Density error

Tank

The density of the product is not

within specifications.

Enter setup and verify the information under density in the probe

programming.

Float height error

Tank

This error could indicate that the

wrong float type is installed or that

a programming error has occurred.

Review probe programming for proper float type, number of floats in

the tank. (This would be an idea time to clean the probe and floats).

Float Missing

Tank

Probe detects a lesser number of

floats than programmed.

Review probe programming for correct number of floats. If correct

then inspect probe shaft, floats, and float magnets. With the probes

out of the tank, this would be an idea time to clean the probe and

floats. If pressures meets requirements specified, contact Franklin

Fueling Systems’ Technical Services Dept. for support on this issue.

FMS configuration error

None

Conflicts exist within FMS

Application programming.

Verify FMS setting are correct in accordance with the site

specifications.

High product level

Tank

Product level exceeded High limit

set. Possible close to tank overfill

condition

Acquire an accurate product level. If actual product level in tank does

not match the consoles displayed current level, verify programming is

correct.

High high product level

Tank

Product level exceeded High High

limit set. Possible tank overfill

condition.

Acquire an accurate product level. If actual product level in tank does

not match the consoles displayed current level, verify programming is

correct.

High product volume

Tank

The specified tank has reached

the programmed High Product

Volume.

Check product volume and compare to the programmed High Volume

alarm Limit in the setup menu. Acquire an accurate product level and

compare to the ATG. If levels differ, verify programming is correct. If

alarm persists, contact FFS Technical Services for support.

High High product volume

Tank

The specified tank has reached

the programmed High High

Product Volume.

Check product volume and compare to the programmed High High

Volume alarm Limit in the setup menu. Get an accurate product

volume and compare to the ATG. If levels differ, verify programming is

correct. If alarm persists, contact FFS Technical Services.